Strip waste edge winding device

A winding device and strip-shaped technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of uneven and tidy winding, unfavorable recycling, and affecting the appearance of the workshop, etc., to achieve Compact structure, good for recycling, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

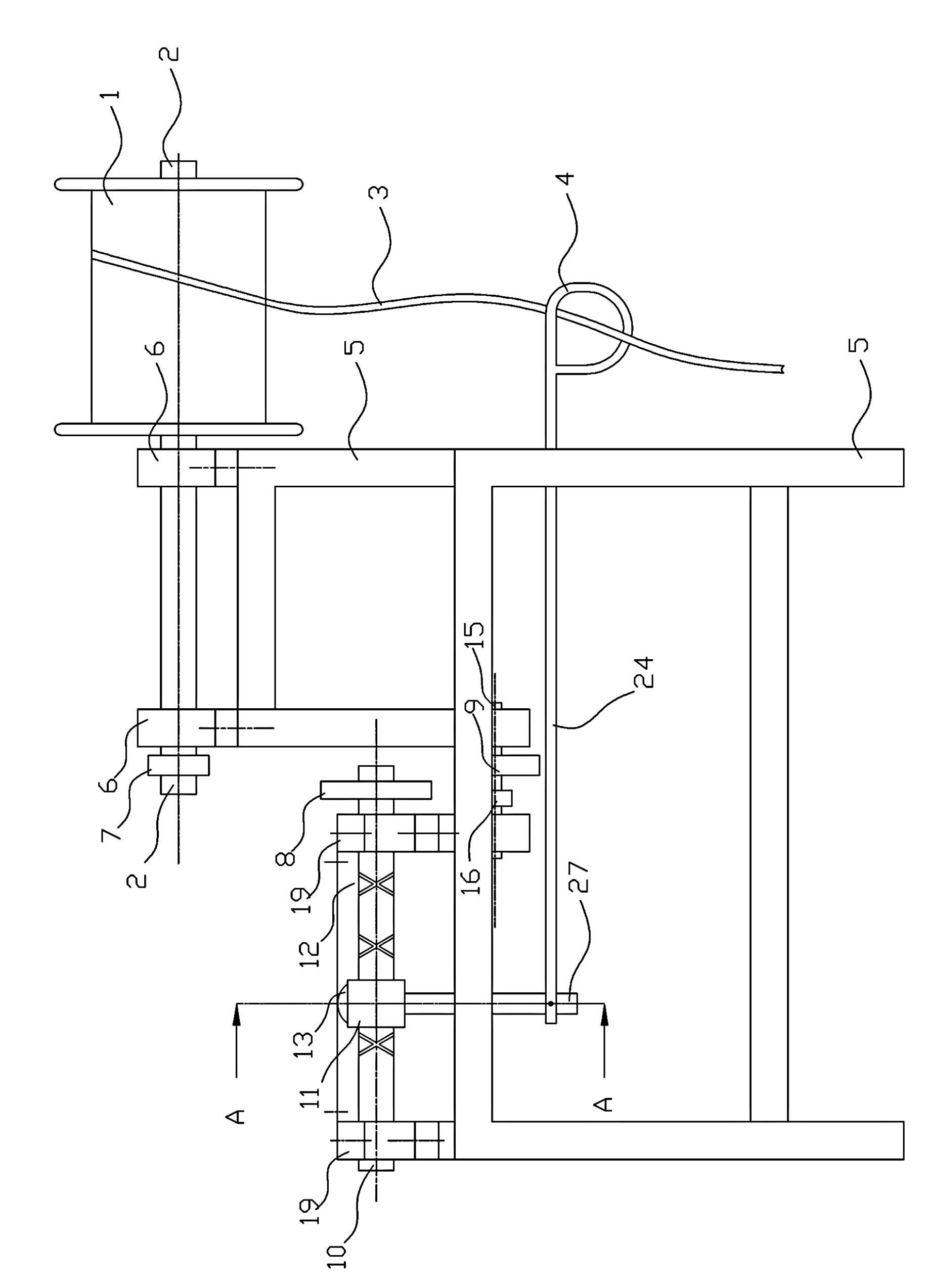

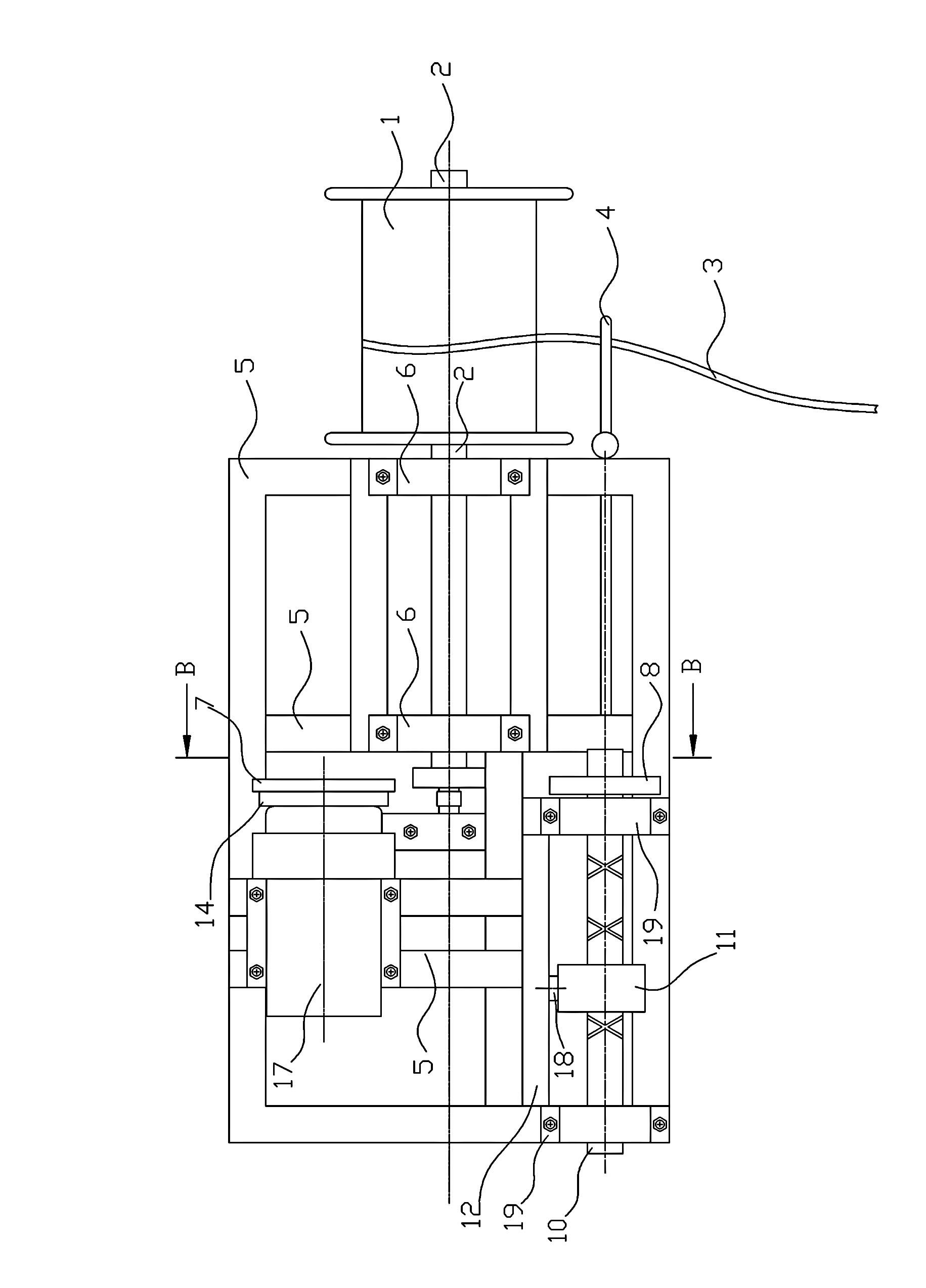

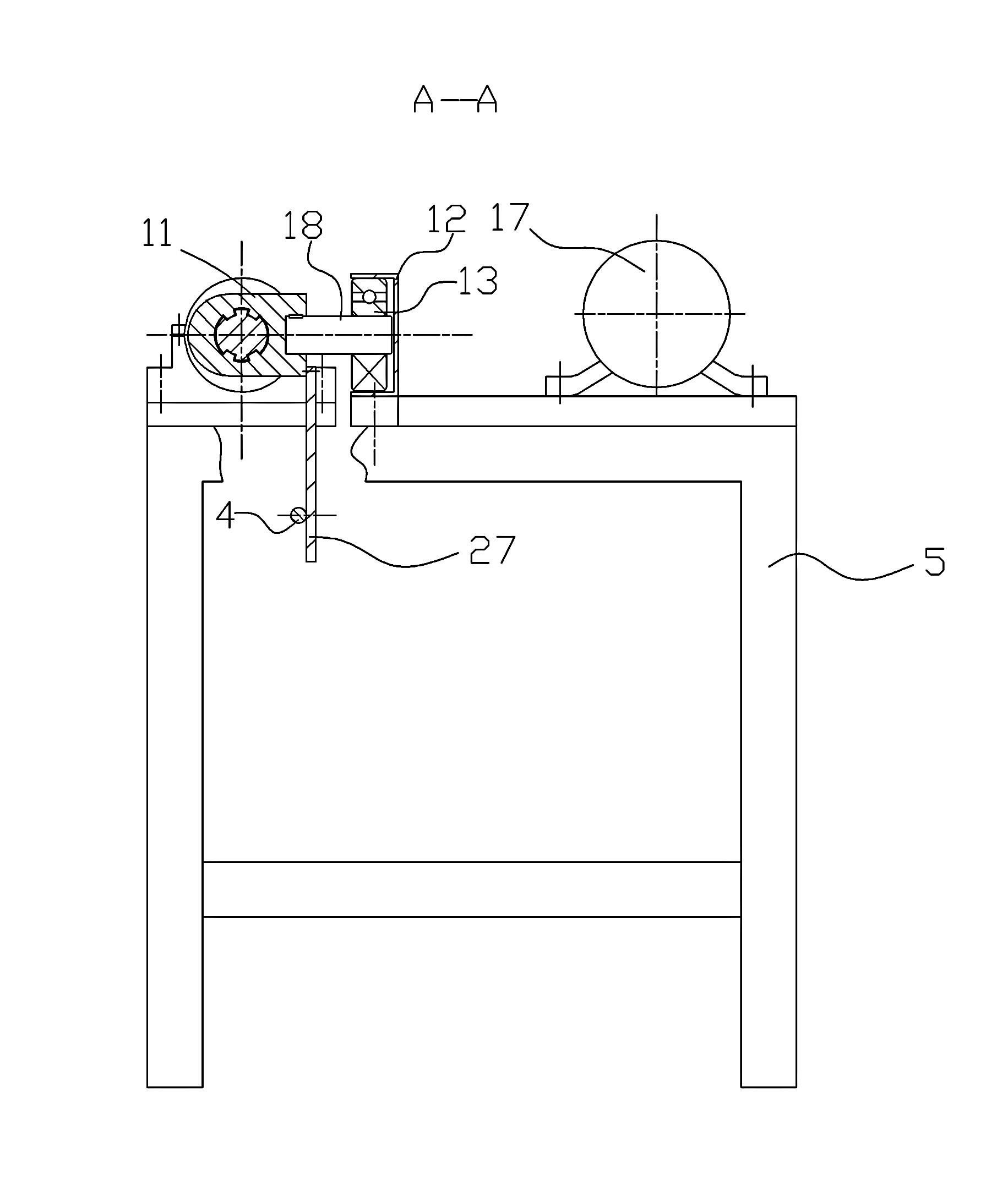

[0016] Such as figure 1 As shown, the axial center of the winding reel 1 passes through a rotating shaft 2, and the winding reel 1 rotates with the rotating shaft 2, and the winding reel 1 passes through the rotating shaft 2 and passes through the bearing seat 6 on the frame 5 to be supported and fixed, and rotates One end that axle 2 stretches into frame 5 is provided with pulley 25, combines figure 2 , Figure 4 , Figure 5 As shown, the frame 5 is provided with a reciprocating shaft 10, a transition shaft 15 and a motor 17, and the two ends of the reciprocating shaft 10 are supported by bearing blocks 19 on the frame 5, and one end of the reciprocating shaft 10 is provided with a pulley 8, and the transition shaft The two ends of 15 are supported by bearing blocks 26 on the frame 5, a sprocket 16 and a pulley 9 are arranged side by side on the transition shaft 15, a sprocket 14 and a pulley 7 are arranged side by side on the output shaft 20 of the motor, and the motor T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com