Integrated ceiling structure

A technology for integrating suspended ceilings and hanging parts, applied in ceilings, building components, building structures, etc., can solve problems such as joints and overall singleness, and achieve the effects of strong three-dimensional effect, avoiding seams, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

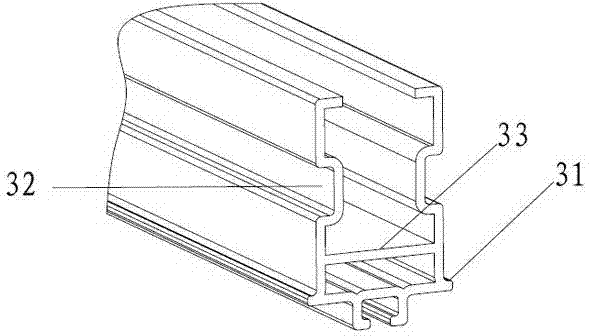

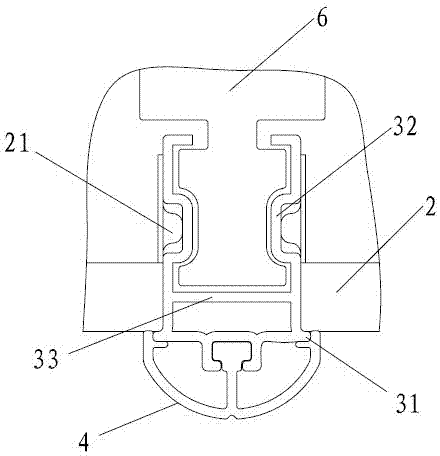

[0035] as attached figure 1 As shown in -6, an integrated ceiling structure, including main joist 1, gusset 2 and auxiliary joist 3, auxiliary joist 3 is connected with main joist 1, and the two sides of the bottom of auxiliary joist 3 are provided with pavement 31, and the two sides of the middle part are limited. Position slots 32 ; bumps 21 are provided on the buckle plate 2 ; the buckle plate 2 is placed on the pavement 31 ; the bumps 21 snap into the limiting slots 32 . A reinforcing rib 33 is arranged inside the auxiliary keel 3 . The gussets 2 are adjacently laid on two parallel auxiliary keels 3; the bottom surface of the auxiliary keels 3 is provided with a decorative strip 4. The integrated suspended ceiling also includes a keel hanger 6 through which the auxiliary keel 3 is connected to the main keel 1 . The decorative strip 4 provided at the bottom of the auxiliary keel 3 can be connected with the decorative strip 4 by way of tenon joint or slide groove.

[0036...

Embodiment 2

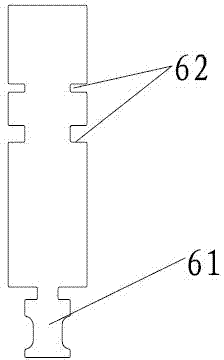

[0040] as attached figure 1 , 2 , 7-14, an integrated ceiling structure, including main keel 1, buckle plate 2 and auxiliary keel 3, auxiliary keel 3 is connected with main keel 1, and paving 31 is arranged on both sides of the bottom of auxiliary keel 3, and the two sides of the middle part A limiting groove 32 is provided; the pinch plate 2 is provided with a bump 21 ; the pinch plate 2 is laid on the pavement 31 ; the bump 21 is snapped into the limiting groove 32 . A reinforcing rib 33 is arranged inside the auxiliary keel 3 . The integrated suspended ceiling also includes inserts 5 arranged perpendicular to the auxiliary keel 3 . Both sides of the bottom of the cutting strip 5 are provided with ribs 51; one side of the top of the cutting strip 5 is provided with a pressure edge 52, and the other side is provided with a pressing piece 53, and the pressing piece 53 is connected with the main body of the cutting strip 5 through a bending part 54; the auxiliary keel 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com