centrifugal fan

A centrifugal fan and centrifugal technology, used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of high noise, high energy consumption, large air volume, etc., to increase air volume and increase air intake. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

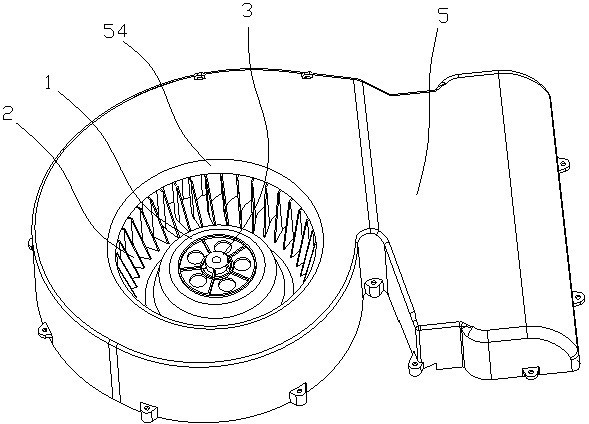

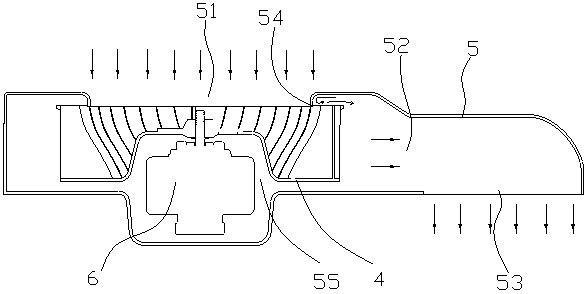

[0030] Centrifugal fans such as Figure 1 to Figure 5 It includes a volute 5, a motor 6 and a wind wheel 1 arranged on the motor 6. The wind wheel 1 includes a base 4 and a wind guide vane 2. The lower end of the wind guide vane 2 is connected to the base 4. The upper end of the wind guide vane 2 passes through the Wheel hoop 3 is fixed. A plurality of air guide vanes 2 distributed at intervals are better fastened into a whole through the tire 1 , and will not shake or twist during high-speed operation.

[0031]There are four or more wind guide vanes 2, which are evenly distributed at equal angles with the geometric center of the base 4 as the center. The wind guide blades 2 are evenly distributed and arranged symmetrically with each other, so that when the wind wheel rotates at high speed, the air volume of each wind guide blade 2 is uniform and equal.

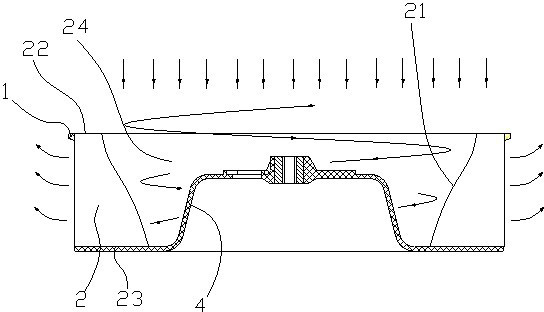

[0032] A negative pressure zone 24 is formed between the wind guide vane 2 and the base 4, the hypotenuse 21 of the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com