Acoustic enclosure sound-absorbing structure

A sound-absorbing and sound-absorbing material technology for covers, which is applied to the components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve the problem of small sound absorption coefficient of the inner wall, poor noise reduction effect, Environmental pollution and other issues, to achieve the effect of improving noise reduction ability, improving sound absorption frequency band, and improving sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

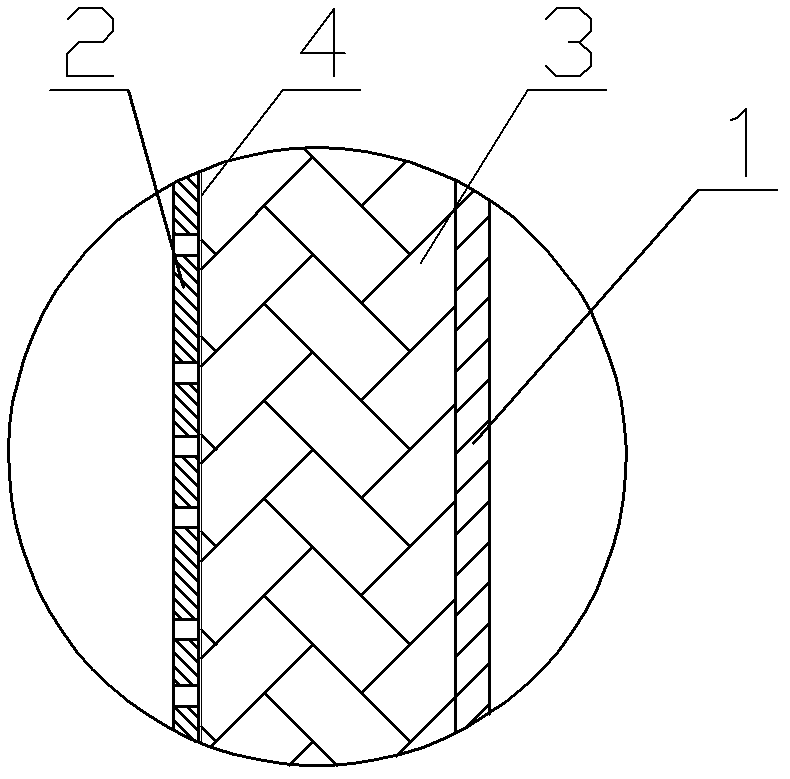

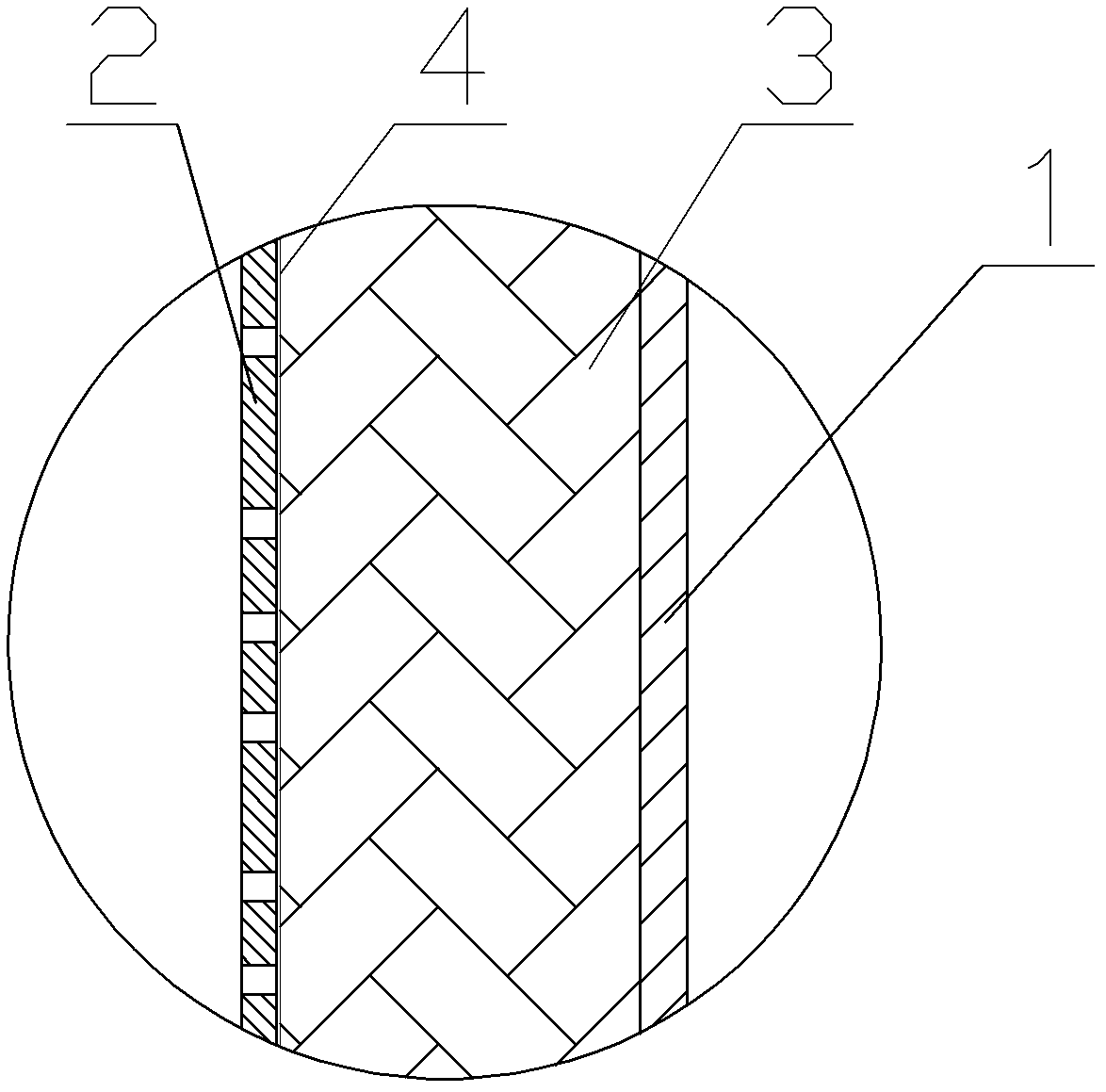

[0013] Such as Figure 1 ~ Figure 2 Shown: Including shell galvanized plate 1, inner wall perforated plate 2, sound-absorbing material 3, glass fiber cloth 4, air intake shutter 5, cooling fan 6 and other components.

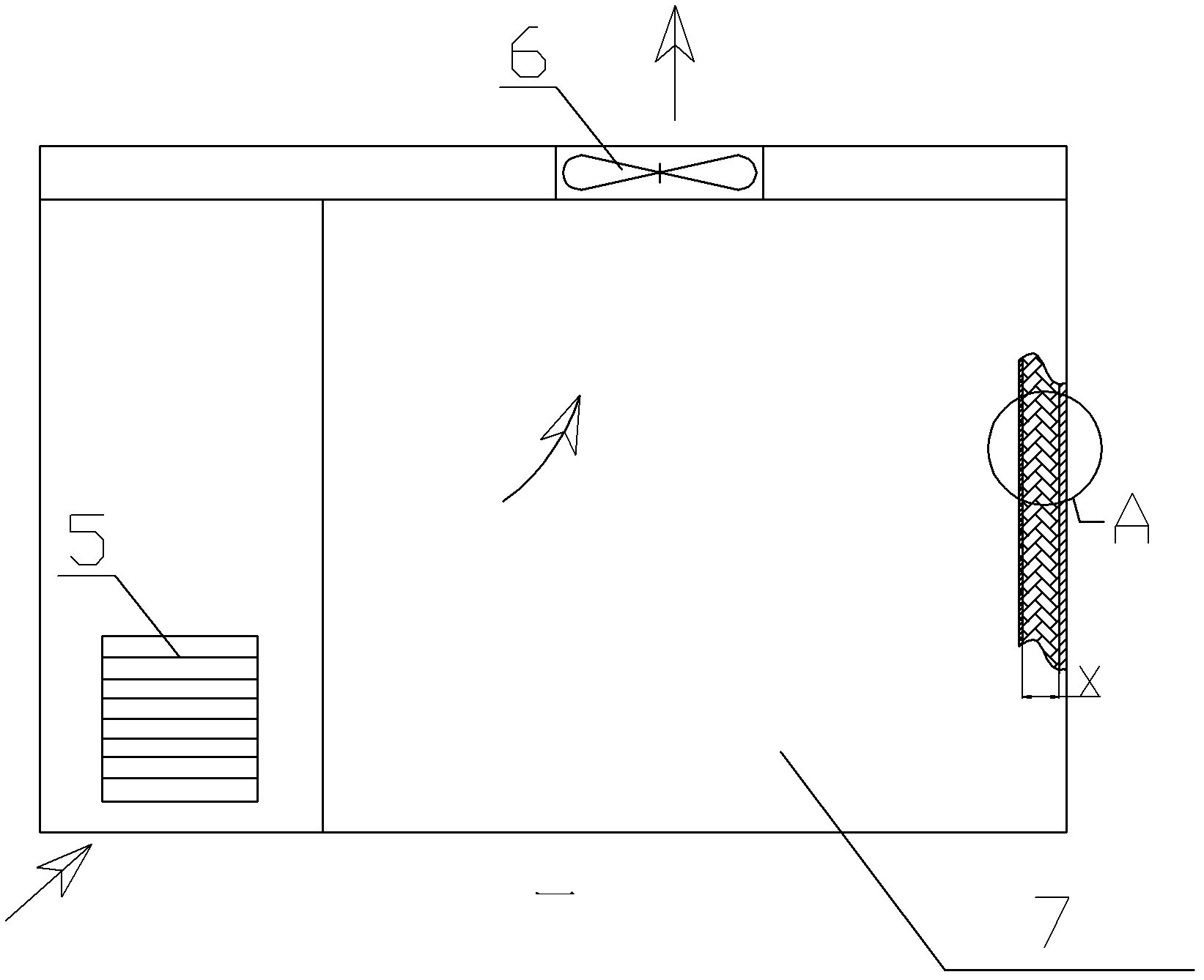

[0014] The soundproof cover includes a soundproof cover body 7, an air intake louver 5, a heat dissipation fan 6, etc., the sound insulation cover body 7 is provided with components such as an air intake louver 5, a heat dissipation fan 6, and the inner wall of the soundproof cover body 7 is provided with a soundproof cover suction acoustic structure.

[0015] The sound-absorbing structure of the sound-proof cover of the present invention includes parts such as a galvanized shell 1 , an inner wall perforated plate 2 , sound-absorbing material 3 , and glass fiber cloth 4 .

[0016] The inner wall perforated plate 2 is provided with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com