Limiting buffer and capacity composite air spring capable of adjusting static stiffness

An air spring, static stiffness technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problem of affecting the comfort of the occupant, the driver's safe driving, the promotion and application of passive air suspension, the occupant and the driver. dizziness and discomfort, to achieve the effect of reliable performance, simple structure and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

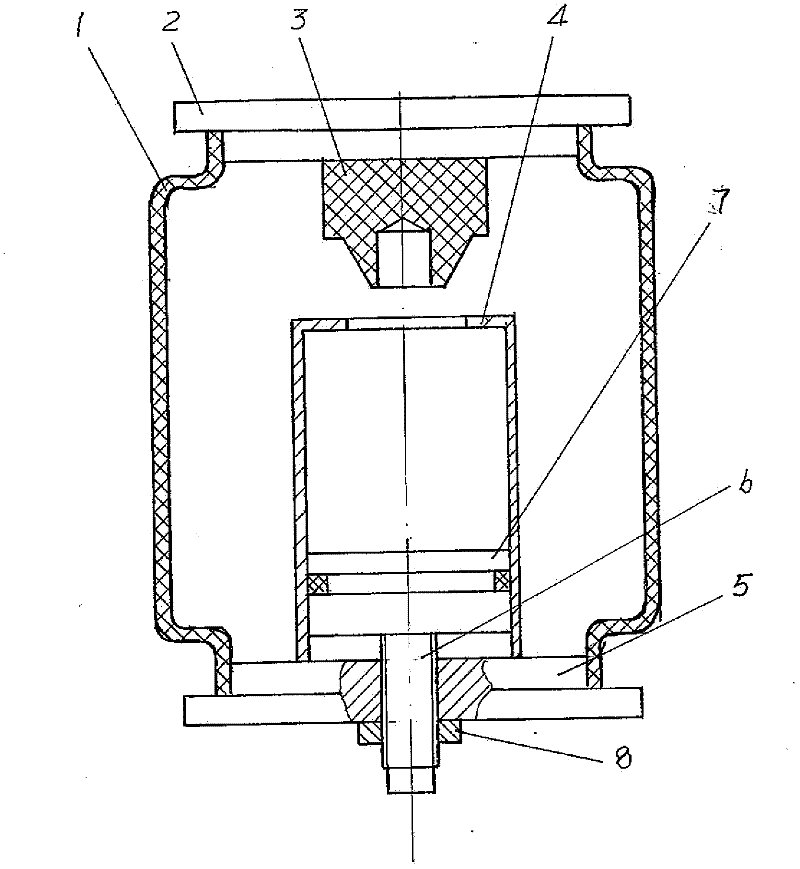

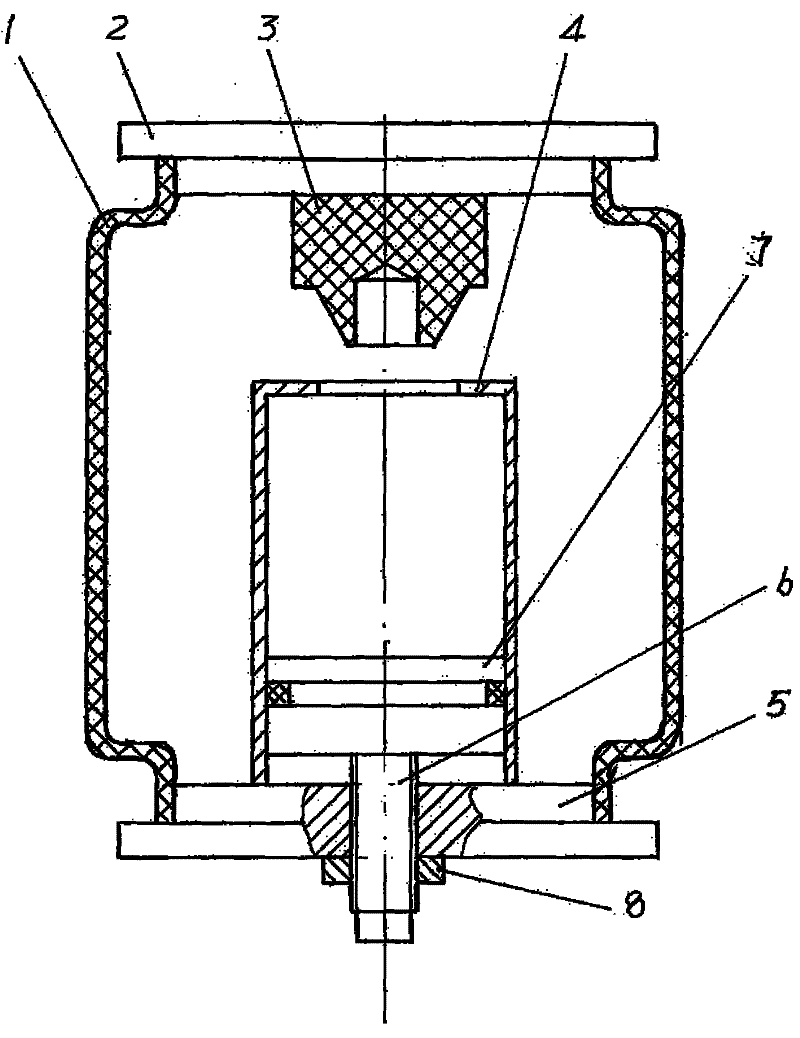

[0007] The static stiffness adjustment of the air spring is simple and easy. The adjustment method is: loosen the lock nut 8, turn the adjusting bolt 6, and move the piston 7 upward, which reduces the effective volume of the gas in the air bag 1 and improves the static stiffness of the air spring; otherwise, it decreases The static stiffness of the air spring; the buffer throttle plug 3 and the buffer air chamber 4 are set in the airbag 1 according to the height of the vehicle body height limiter. When the vehicle encounters a heavy dynamic load during operation, it suddenly rushes to the limit seat , the buffer throttle plug 3 enters the upper circular hole of the buffer air chamber 4 in advance, at this time, the air bag 1 is equivalent to the main air chamber, the buffer air chamber 4 is equivalent to the auxiliary air chamber, and the upper parts of the buffer throttle plug 3 and the buffer air chamber 4 The round hole is equivalent to the throttle valve between the main a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com