Furnace tube ignition method

A furnace tube and ignition chamber technology, applied in the direction of combustion ignition, combustion method, igniter equipped with fuel, etc., can solve the problems of affecting production efficiency, product wafer scrapping, high ignition failure rate, etc., to improve the ignition success rate, loss avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

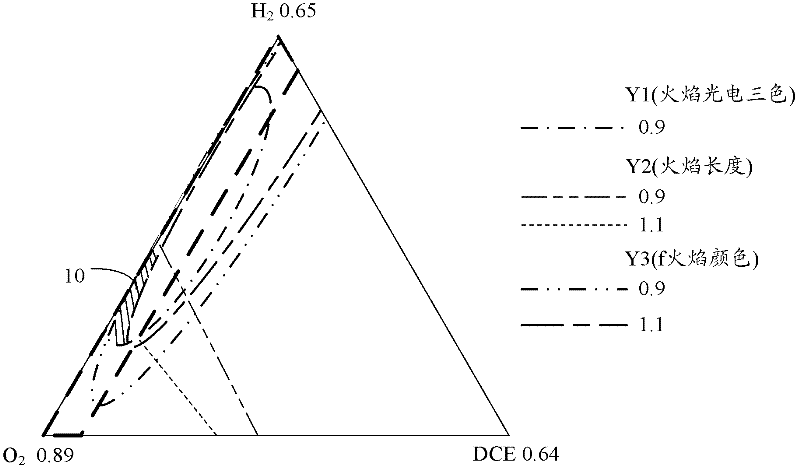

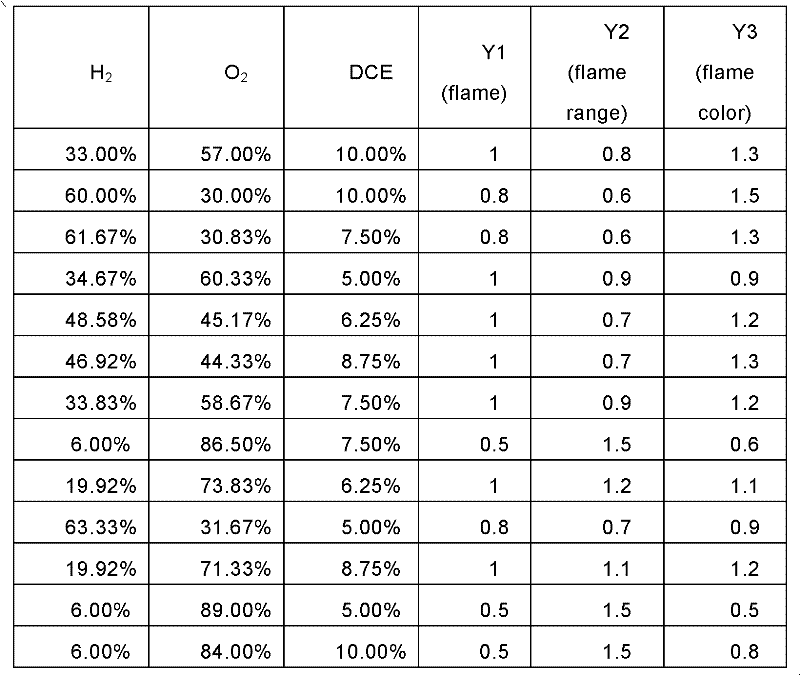

[0016] In the prior art, the ignition mixing ratio of the ASM400 atmospheric pressure furnace tube is generally the ratio of hydrogen to oxygen is 1:2, but the failure rate of ignition is relatively high under this ratio, and it will be used in batch industrial production. cause greater losses.

[0017] In the furnace tube ignition method of the embodiment of the present invention, the ratio of hydrogen and oxygen passed into the ignition chamber of the furnace tube during the ignition process ranges from 1:2.5 to 1:2.7, and the use of this ratio can effectively improve the success rate of ignition , to reduce or avoid losses caused by ignition failure.

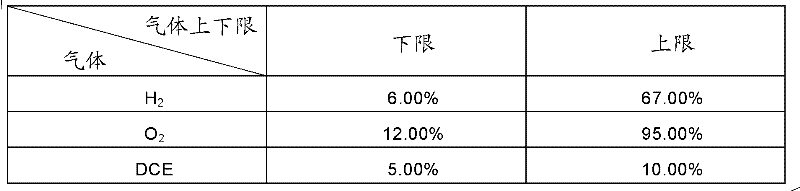

[0018] Further, the embodiment of the present invention optimizes the ignition conditions of the ASM400 atmospheric pressure furnace tube. The gas ratio of the ignition chamber during the ignition process is: hydrogen 26%-28%, oxygen 66%-68, dichloroethylene 4 % to 6%, thus reducing the ignition success rate of the ASM400 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com