Film inspection device

An inspection device and film technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of high labor intensity, affect the inspection effect, easy to produce fatigue, etc., and achieve the effect of simple structure, guaranteed inspection effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

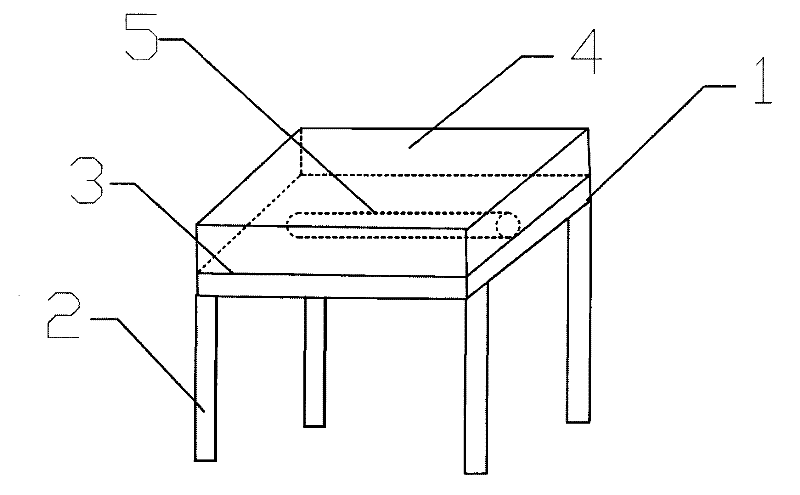

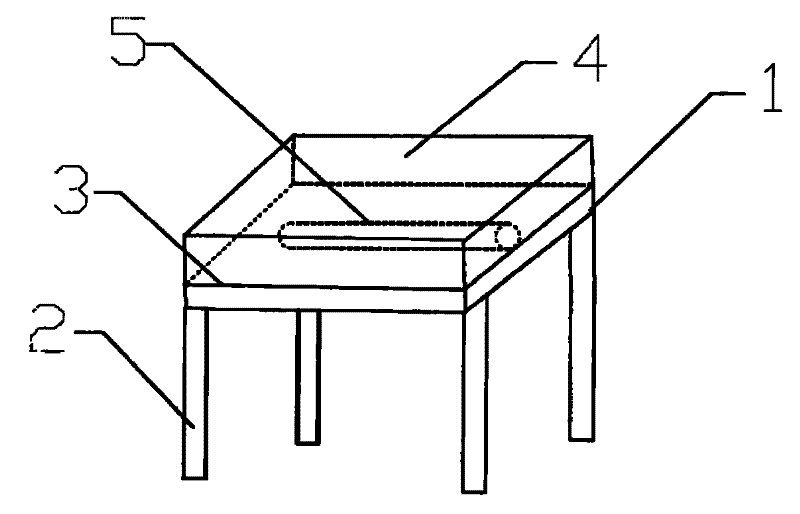

[0016] A kind of checking device of film sheet of present embodiment, as figure 1 As shown, it includes a table body, which includes a desktop 1 and table legs 2; it also includes a light box, the bottom plate 3 of which is fixed on the desktop 1, and the top of the light box is a white transparent plate 4, which is a glass plate or an acrylic plate Or any kind of plexiglass plate; the base plate 3 is provided with a white light source 5, which is any one of a fluorescent lamp, an incandescent lamp, a fluorescent lamp or a light-emitting diode.

[0017] When applying this embodiment, it is only necessary to turn on the above-mentioned light source 5, place the exposed film sheet close to the light-transmitting plate 4, and check whether the film sheet has trachoma, whether the drug film has scratches, oil stains, light loss, dirty spots, Vignettes, laser lines, creases, etc. This embodiment effectively solves the problem of high labor intensity and easy fatigue during long-te...

Embodiment 2

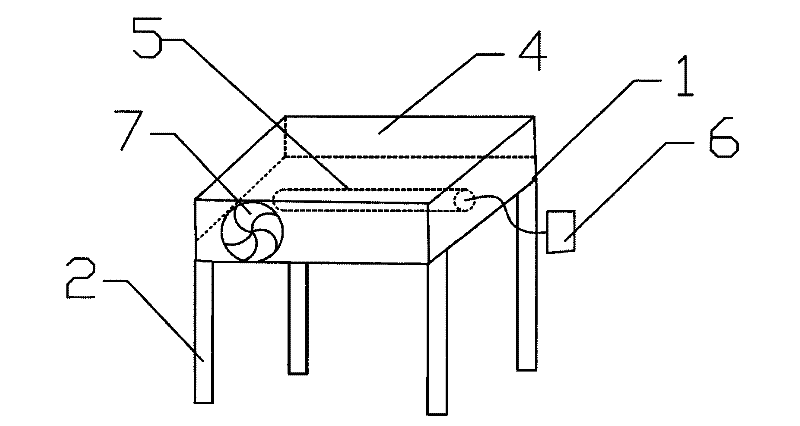

[0019] A kind of checking device of film sheet of present embodiment, as figure 2 As shown, it includes a table body, which includes a desktop 1 and table legs 2; it also includes a light box, the light box is a closed structure with the desktop 1 of the table body as the bottom plate, and the top of the light box is a white transparent plate 4, It is any one of a glass plate, an acrylic plate or a plexiglass plate; a white light source 5 is provided on the desktop 1, which is any one of a fluorescent lamp, an incandescent lamp, a fluorescent lamp or a light-emitting diode. The light source 5 is connected to the dimmer 6 which also has the switch function, and a cooling fan 7 is also arranged in the light box.

[0020] When applying this embodiment, it is only necessary to turn on the above-mentioned light source 5 and adjust it to a suitable brightness by adjusting the dimmer 6 which also has a switch function, and place the exposed film sheet close to the light-transmitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com