Board-to-Board Connector

A board-to-board connector and connector terminal technology, applied in the direction of connection, fixed connection, contact parts, etc., can solve the problems of poor tin climbing, affecting the conduction of the board-to-board connector, etc., and the strength of the connection will not be affected. The effect of influencing and inhibiting poor tin climbing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

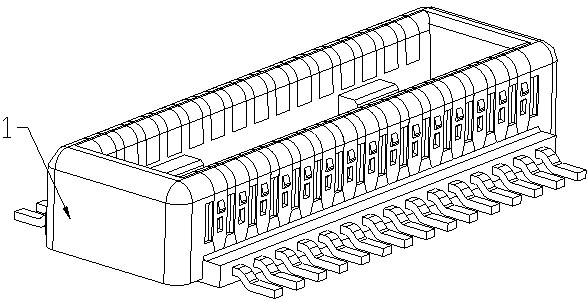

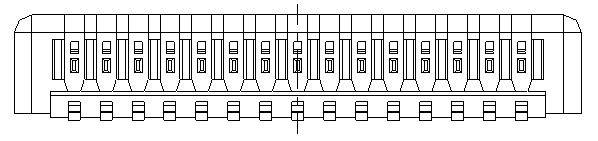

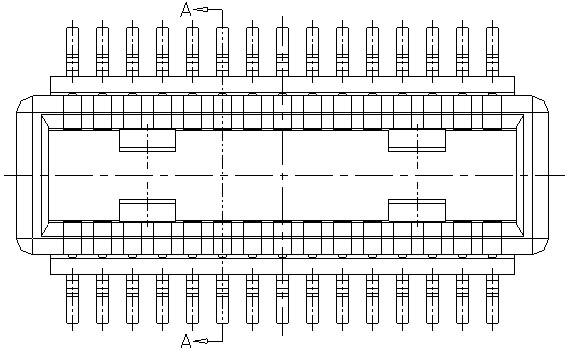

[0019] Such as Figure 1-5 As shown, a board-to-board connector includes an insulating body 1 and several connector terminals, each connector terminal is held in a corresponding receiving cavity of the insulating body 1, and the connector terminals include a terminal body 2 and solder pins 3. On both sides of the bottom of the terminal body 2, solder feet 3 for welding are respectively protruded, and contact ports 4 are respectively provided on both sides of the terminal body 2, and at least one of the solder legs 3 is connected to the terminal body 2 Bend structure 5 upwards. During soldering, upwardly bending the structure 5 will cause resistance to the flow of tin, so that the tin will not climb to the contact port 4, which has the effect of inhibiting the bad tin climbing. In order to better suppress the defect of tin creeping, multiple upward bending structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com