Overhead Line Leaping Robot Walking Device

An overhead line and traveling device technology, which is applied to overhead lines/cable equipment, manipulators, manufacturing tools, etc., can solve the problems of increasing difficulty, easy falling, and multiple bifurcations, and achieves easy popularization and application, low manufacturing cost, and structure. Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

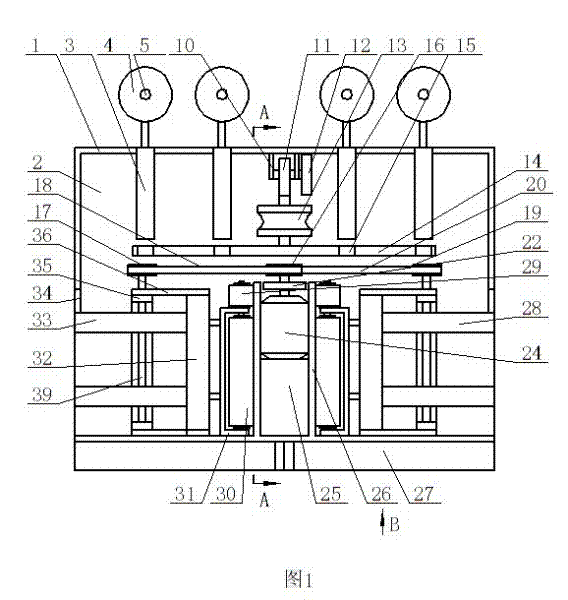

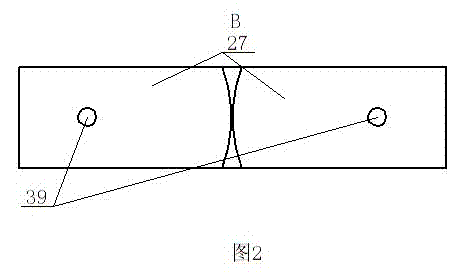

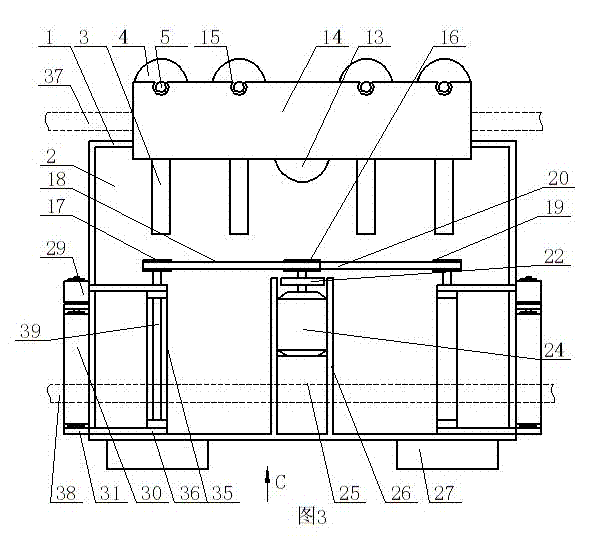

[0009] Overhead line straddling robot walking device of the present invention, as figure 1 As shown, it includes a housing 1, an inner chamber 2 is provided in the housing 1, four first buffer rods 3 are fixedly installed on the upper part of the inner chamber 2, and the first guide rod 46 of each first buffer rod 3 extends out of the housing. 1 travel motor 40 is installed outside, and travel sheave 4 is installed on the output shaft of travel motor 40. For convenience, the robot is suspended on the overhead line by the walking sheave 4, such as Figure 5 and Figure 6 As shown, all the running sheaves 4 are located at the front top of the housing 1. Such as figure 1 As shown, the lower part of the inner cavity 2 is symmetrically installed with two barrier-crossing brackets 28 with the central axis of the inner cavity 2 as the midline. Such as figure 1 and Figure 6 Shown, each straddling obstacle bracket 28 is connected and constituted by U-shaped support 35, connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com