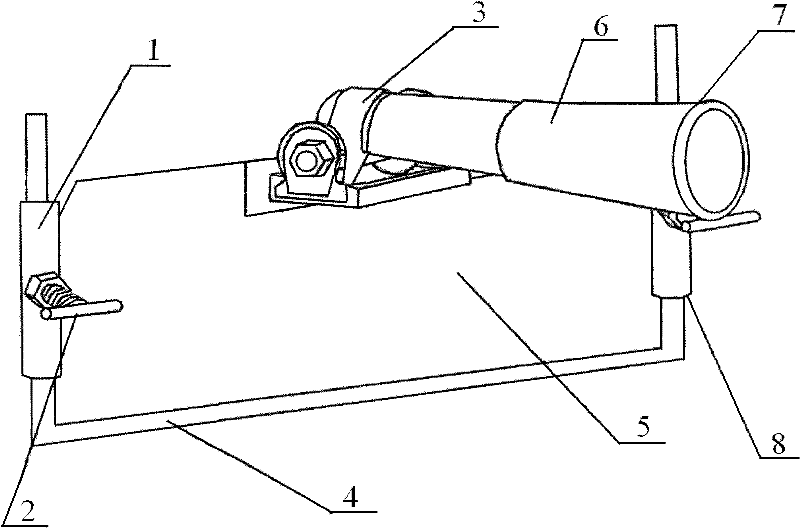

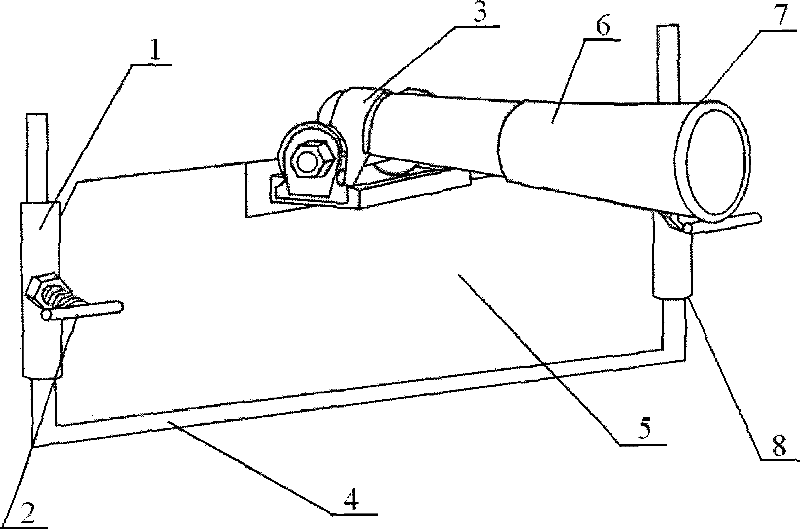

Structure of a New Grain Spreading Rake

A new, U-shaped technology, applied in the direction of drying and preserving seeds, can solve the problems of high labor intensity, poor sunlight effect, and time-consuming, and achieve the effects of uniform thickness, improved labor efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Install the fixing sleeve (1) symmetrically at the two ends of the grain spreading board (5), and the both sides of the U-shaped bar (4) are fixed on the fixing sleeves (5) both sides of the grain spreading board (5) with adjusting screws (2). 1), install a fixed angle adjustment frame (3) on the upper part of the middle part of the grain spreading board (5), and install a fixed handle (5) on the angle adjustment frame (3); when turning the grain, the U-shaped bar (4) 1. Adjust the distance between the cross bar of the fixed sleeve hole (8) and the grain spreading board (5) to the required width, then let the U-shaped bar (4) cross bar stick to the ground, adjust the handle (6) and Angle between the grain spreading boards (5), pulling the handle (6) and the handle handle (7) just can spread the grain to the thickness of setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com