An automatic rotary bagging device

A bagging device and automatic rotation technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problems of inconvenient use, high labor intensity and low efficiency of operators, and achieve convenient adjustment, fast and convenient adjustment, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the accompanying drawings.

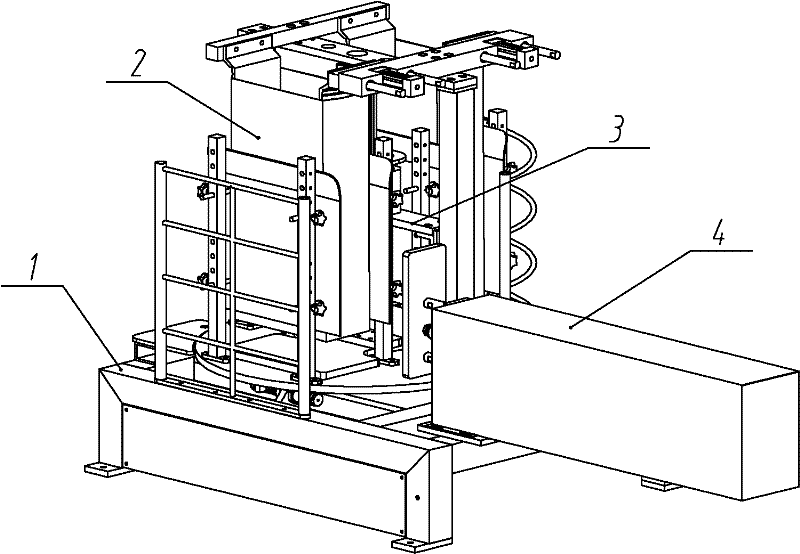

[0030] Such as figure 1 As shown, the present invention includes a rotating mechanism 1, a bag clamping mechanism 2, a beating and shaping mechanism 3 and a bag pushing mechanism 4, and the bag clamping mechanism 2 is locked on the turntable 1-6 of the rotating mechanism 1 through two columns 2-12 , the beam 3-10 of the beating and shaping mechanism 3 is directly fixed between the two columns 2-12 of the bag clamping mechanism 2, and the bracket plate 4-8 of the bag pushing mechanism 4 is locked on the frame of the rotating mechanism 1 On the small platform to the right of 1-4.

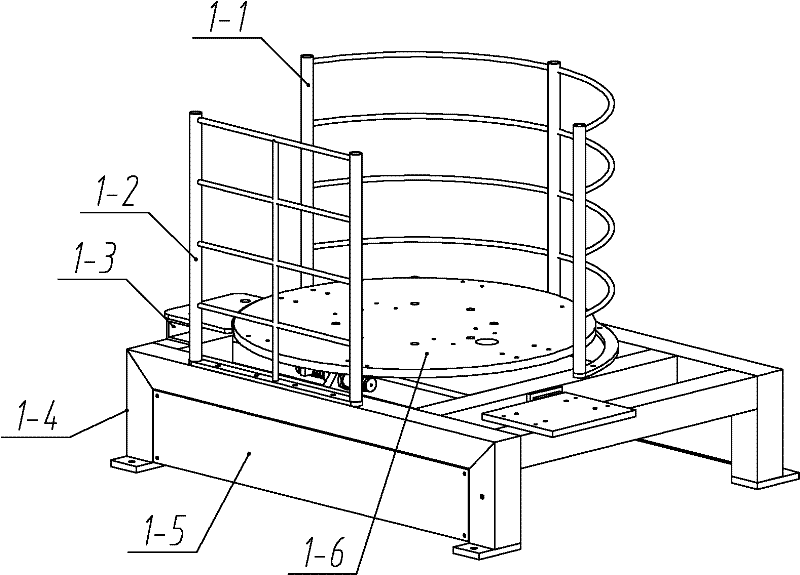

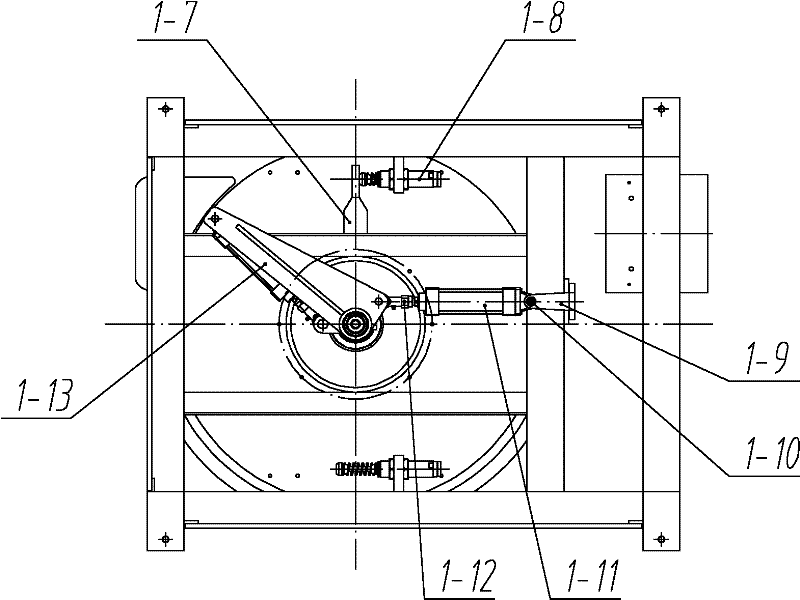

[0031] Such as figure 2 , image 3 and Figure 4 As shown, the rotating mechanism 1 includes a semicircular guardrail 1-1, a vertical guardrail 1-2, a transition plate 1-3, a frame 1-4, three cover plates 1-5, a turntable 1-6, rotating shaft 1-7, two oil pressure buffers 1-8, cylinder tailstoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com