Rail-mounted crane end stop

A crane and rail-type technology, which is applied in the field of end stoppers, can solve problems such as structural reliability and unsatisfactory stopper effect, and achieve good stopper effect, buffer impact and increase friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

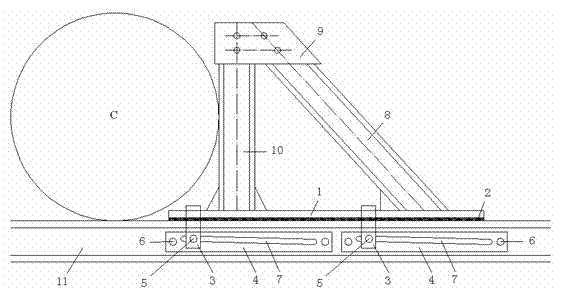

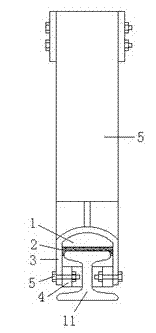

[0016] The present invention will be described below with reference to the accompanying drawings.

[0017] When the crane slides to the end of the track, the wheel touches the front baffle of the stopper and pushes the stopper to slide forward, so that the folding lock buckle slides along with it, and at the same time, the high-strength bolts on the folding lock buckle slide along the chute. Because the chute is inclined downward at a certain angle along the sliding direction of the high-strength bolts, the high-strength bolts slide and tighten the folded locks at the same time, the steel blocks of the rail will be locked tighter and tighter, and the pressure on the rails will be greater and greater. The frictional force received by the stopper is getting bigger and bigger, so as to achieve the thrust purpose.

[0018] The stopper is installed at the end of the track, and the bar-shaped steel block with a chute is fixed on both sides of the track. The high-strength bolts on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com