Fixed height-adjustable steel rail support capable of controlling paving thickness of cast-in-situ concrete

A technology of concrete and steel rails, applied in the direction of buildings, building structures, etc., can solve the problems of lodging, no fixed connection method, and can not meet the accuracy requirements, and achieve the effect of preventing horizontal movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

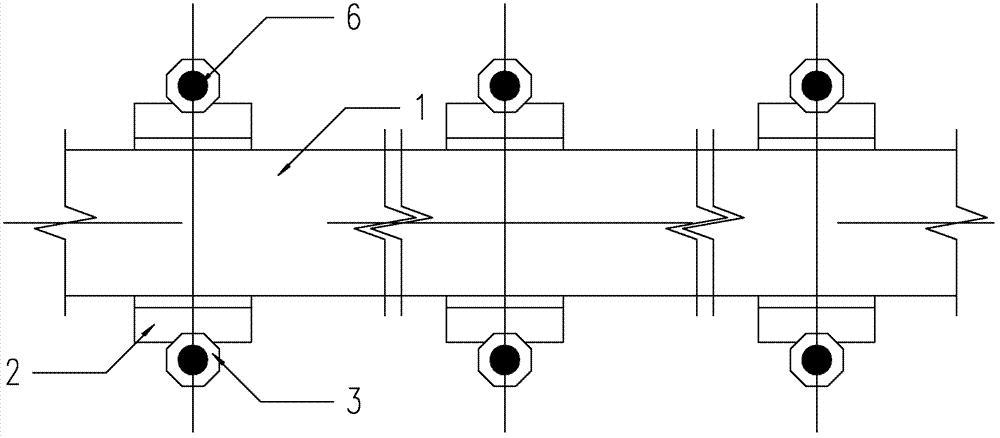

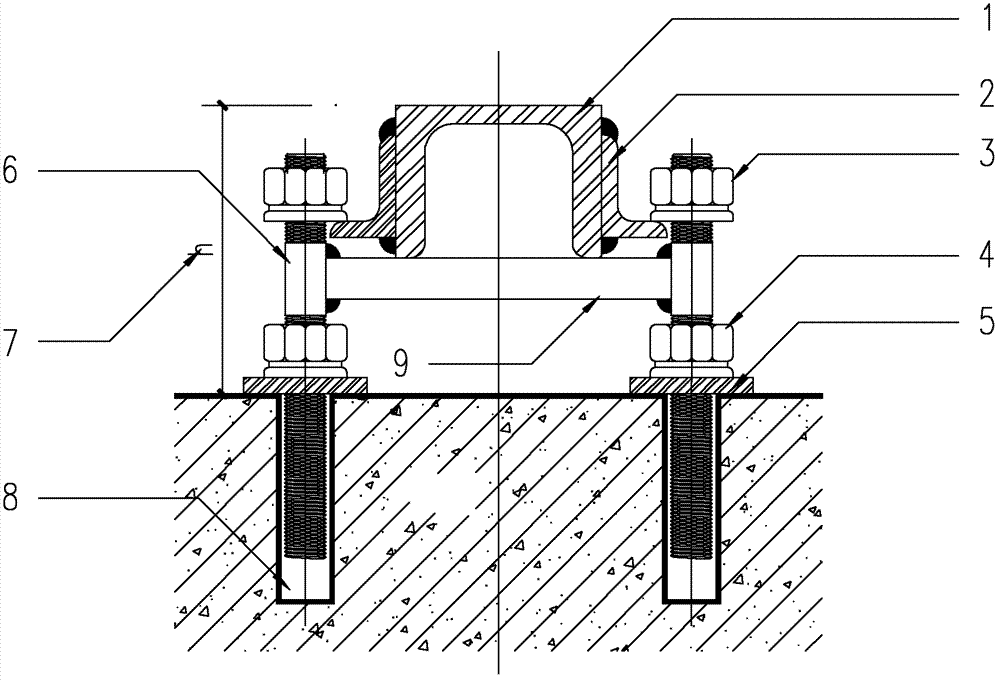

[0012] The fixed and height-adjustable rail support structure for controlling the thickness of paving cast-in-place concrete of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0013] The fixed and adjustable height rail support for controlling the thickness of cast-in-place concrete ground paving according to the present invention, the rail support is arranged under the shaped steel track to support and fix the shaped steel track, and adjust the height of the shaped steel track. The rail support includes a belt wire Buckle legs 6, beams 9, adjustable nuts 4, steel gaskets 5, fastening nuts 3; the two ends of the beams 9 are respectively fixedly connected with thread buckle legs 6, forming H-shaped brackets with the beams 9, two straps The lower end of the threaded support foot 6 passes through the adjustable nut 4 and the steel washer 5, and the lower ends of the two support feet go deep into the preset hole 8; The lug p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com