Spotting drill bushing

A technology of drill sleeves and positioning grooves, which is applied in the direction of drilling templates for workpieces, etc., which can solve the problems of unstable positioning and complex structures of drill sleeves, and achieve the effects of simple structure, large contact area, and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

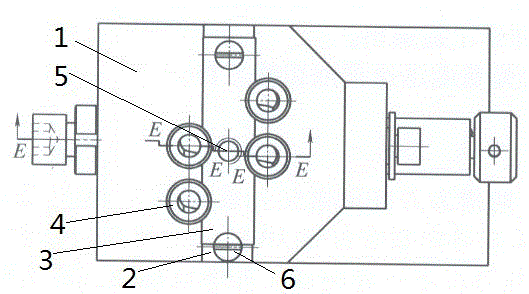

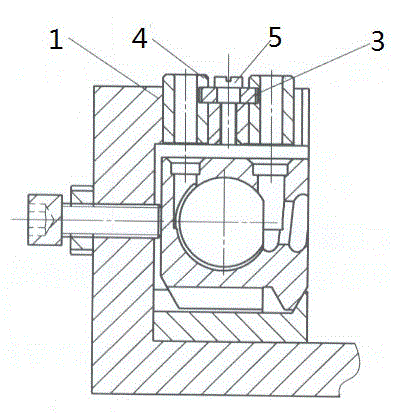

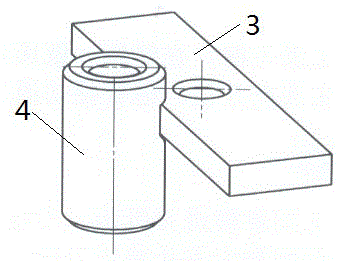

[0014] The reference numerals in the accompanying drawings of the description include: a drill template 1 , a through slot 2 , a flashboard 3 , a drill sleeve 4 , a first locking screw 5 and a second locking screw 6 .

[0015] Examples are attached Figure 1~3 As shown, in this embodiment, the drill sleeve is positioned, and a through groove 2 is opened on the top of the drill template 1. The through groove 2 is a stepped groove with a limiting bottom groove, and the inserting plate 3 is placed in the limiting bottom groove. The flashing plate 3 has the function of positioning, preventing the flashing plate 3 from moving horizontally.

[0016] The middle part of the flashboard 3 is fixed to the drill template 1 by the first locking screw 5, and the two ends of the flashboard 3 are fixed to the drill template 1 by two second locking screws 6.

[0017] Four vertical drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com