A cushion block for fixing concrete flanging side formwork

A technology of concrete and pads, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc. It can solve problems such as difficulty in pouring, inability to place flat, time-consuming side forms, etc., to achieve The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

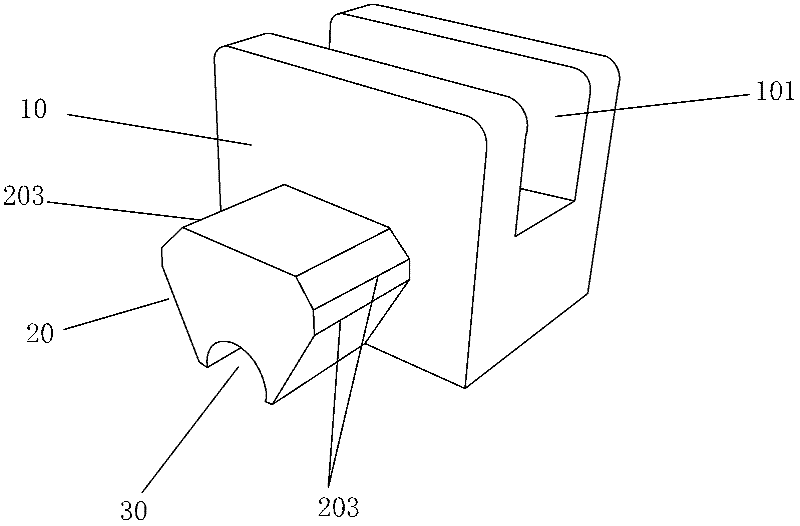

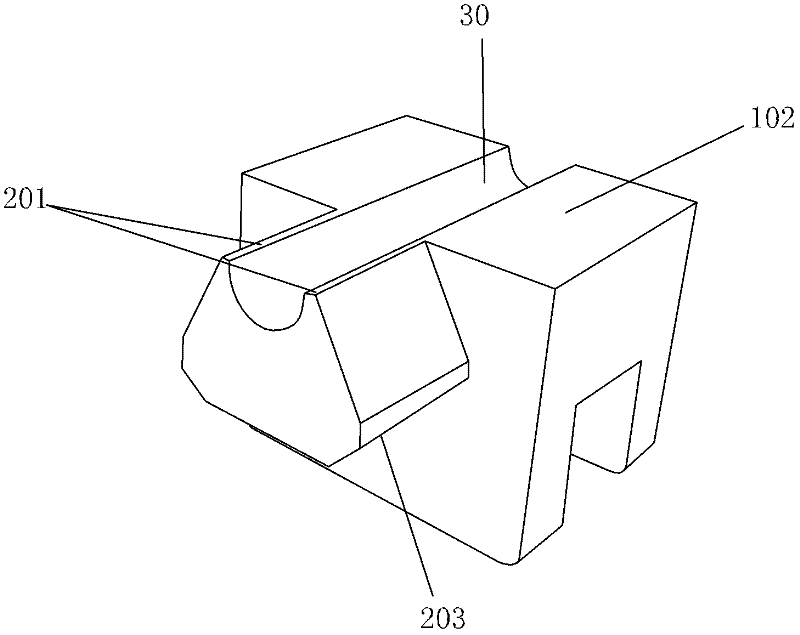

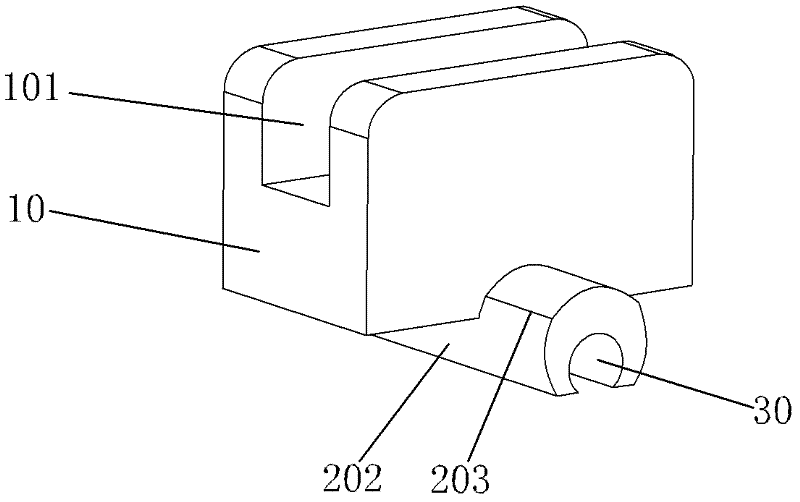

[0025] The present invention will be further described below with specific embodiment, see Figure 1-10 :

[0026] A spacer for fixing concrete flanging side forms, in the center of the spacer body 10 from the upper plane to the bottom plane, there is a groove 101 for positioning formwork longitudinally through, and in the spacer body 10 parallel to the groove 101 There is an installation position 20 extending outwards from the center of the lower part of one side, the bottom plane 201 of the installation position 20 is flush with the bottom plane 102 of the pad body 10 or the bottom 202 of the installation position 20 is exposed outside the bottom plane 102 of the pad body 10, At the center of the bottom 202 of the installation position 20 and the bottom of the block body 10 is a through steel bar installation groove 30 perpendicular to the groove 101 .

[0027] The cross-section of the installation position 20 mentioned above is a regular trapezoid or an inverted trapezoid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com