A closed dust removal method and system for a tunneling face

A closed-type technology for excavating working face, applied in the direction of earth-moving drilling, slitting machinery, etc., can solve the problem that the dust concentration of the working face cannot be reduced to a safe range, hinder the work of the on-site staff, and affect the sight of the driver, etc. The design method is simple and practical, the dust removal effect is good, and the effect of ensuring the air suction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

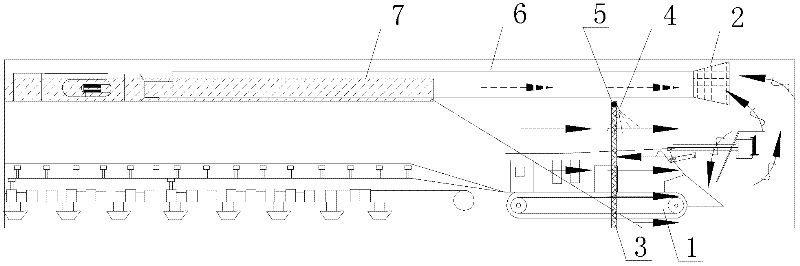

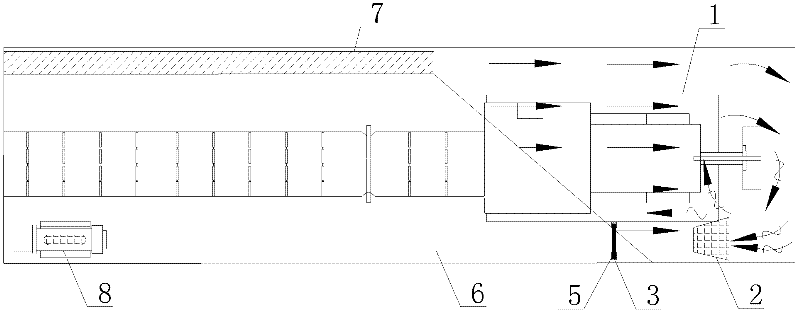

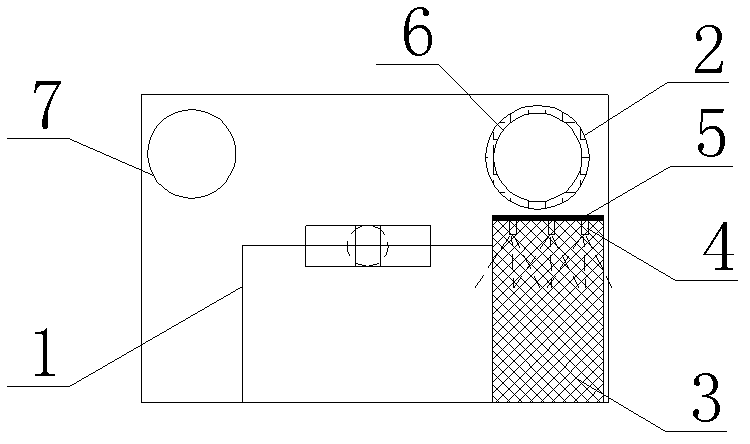

[0024] combine figure 1 , figure 2 and image 3 In the following, the enclosed dust removal method for the excavation face will be described together with the closed dust removal system for the excavation face in the present invention.

[0025] A closed dust removal system for a tunneling face, comprising a press-in fan, a press-in air cylinder 7, a metal frame gauze 3, an atomizing nozzle 4, a dust removal fan 8 and a draw-out air cylinder 6.

[0026] The above-mentioned press-in air cylinder 7 is suspended on the top plate above the side of the roadway where the driver's station of the roadheader is located. Blow out to form an air curtain that can close the entire working section of the roadway, and at the same time blow the dust to the other side of the roadway. This method can form an air curtain covering the entire section to prevent high-concentration dust from spreading to the manned operation area behind the heading head, and at the same time, blow the dust produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com