Adverse slope excavating construction method of large-section tunnel in water-rich tunnel section

A construction method and large-section technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as poor construction conditions, increased excavation operation time, and potential safety hazards of construction personnel and equipment, so as to improve construction efficiency, The construction sequence is reasonable and the effect of improving the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

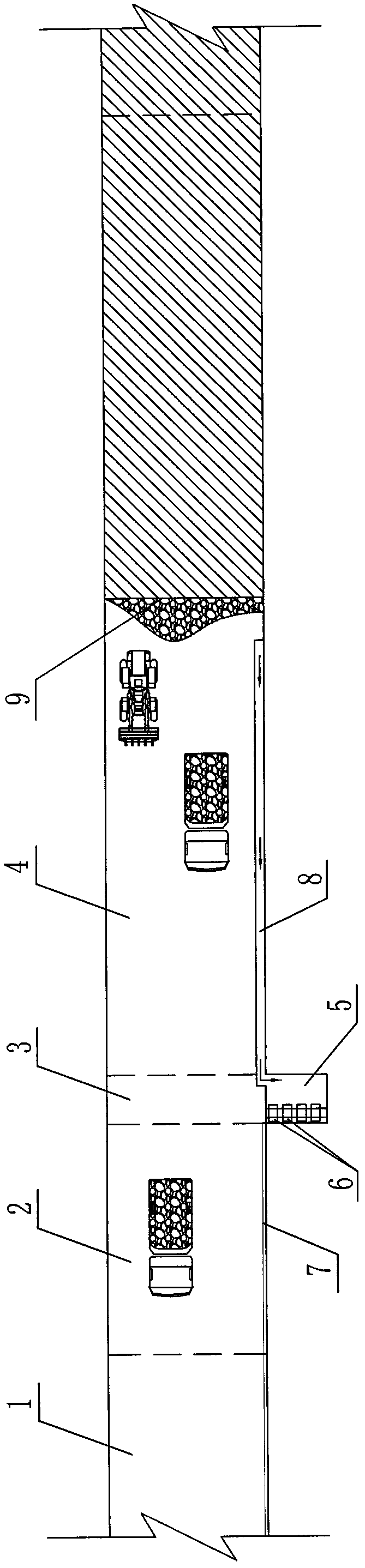

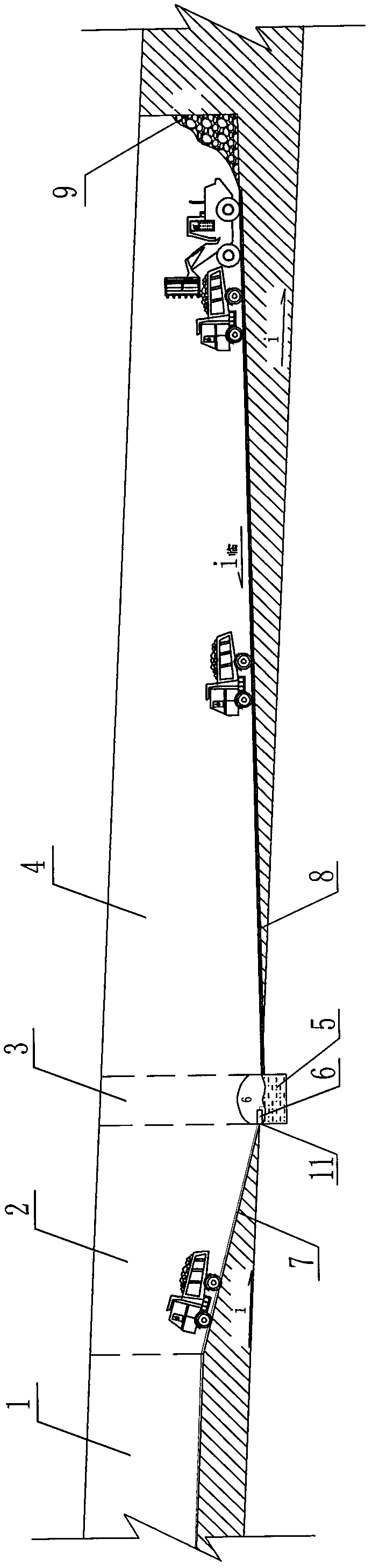

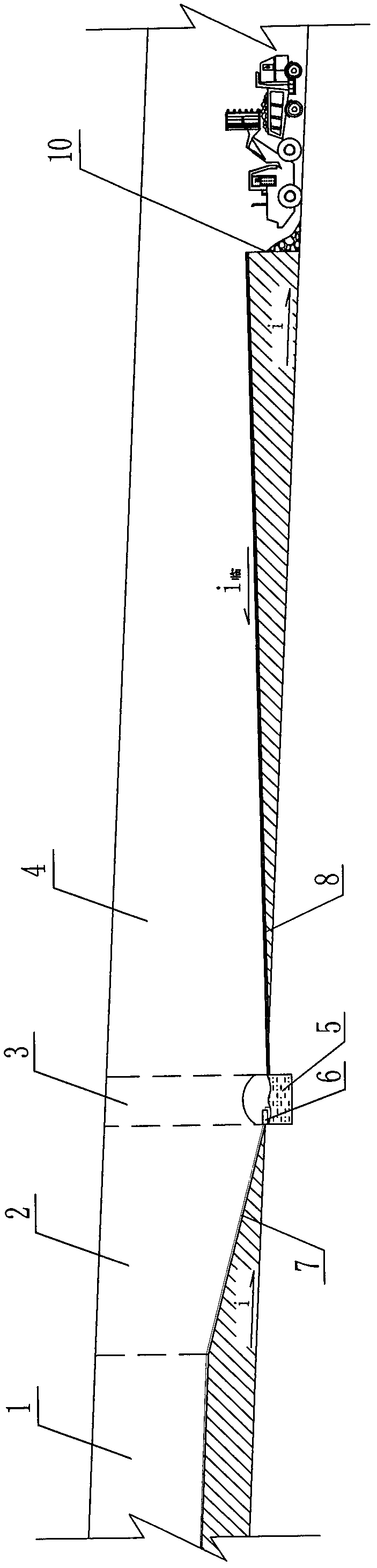

[0018] Figure 1 ~ Figure 3 An embodiment of the construction method for excavating the reverse slope of the large-section tunnel in the rich water tunnel section of the present invention is shown, and the specific construction steps are as follows:

[0019] a. Firstly excavate the tunnel at a position higher than the design floor elevation 11 of the tunnel to form an upper step excavation section 1 . (At this time, the excavation face of the tunnel has not yet entered Fushui Tunnel Section 4)

[0020] b. Before the excavation face enters the water-rich tunnel section 4, the tunnel is excavated according to the longitudinal slope with a slope ratio of less than 10% downhill to form the upper step downhill tunnel section 2, and the end of the upper step downhill tunnel section 2 is connected to the The tunnel design floor elevation is 11 level. That is, the upper step excavation tunnel section 1 descends the slope to the tunnel design floor elevation 11 through the upper step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com