Testing method for parallelism and roughness of bearing axial end face

A detection method, axial end technology, used in measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

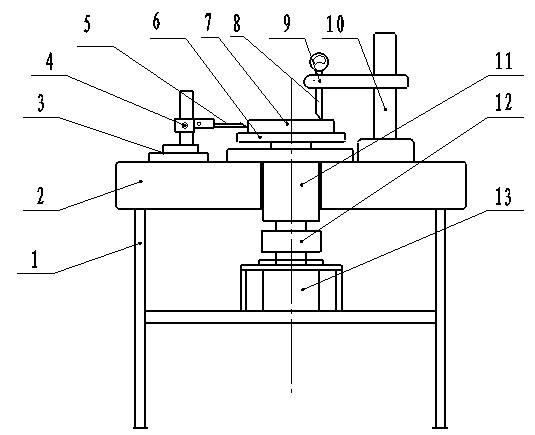

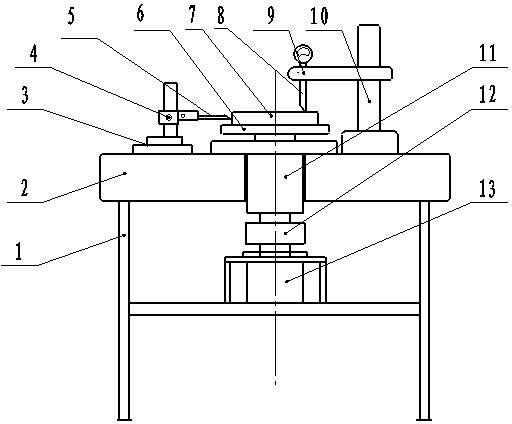

[0015] combine figure 1 , the present invention is a method for detecting the parallelism and roughness of the axial end face of a bearing. The width end face of the bearing is defined as the axial end face of the bearing, and the outer diameter end face of the bearing is defined as the radial end face of the bearing. Since the bearing has an outer ring and an inner ring, and the width of the outer ring is either equal to the width of the inner ring or not equal to the width of the inner ring, the detection method of the present invention can detect the parallelism and roughness of the axial end surface of the outer ring of the bearing as well as Detect the parallelism and roughness of the axial end face of the inner ring of the bearing.

[0016] In this detection method, firstly, the bearing 7 to be tested is placed on the measuring platform 6. The lower end of the measuring platform 6 is connected to the main shaft 11 and is perpendicular to the main shaft 11. The main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com