Device and method for measuring vertical component of magnetic induction intensity by optical pump

A technology of magnetic induction intensity and vertical component, applied in the field of magnetic signal measurement, achieves the effects of low cost, convenient operation and simple structure combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

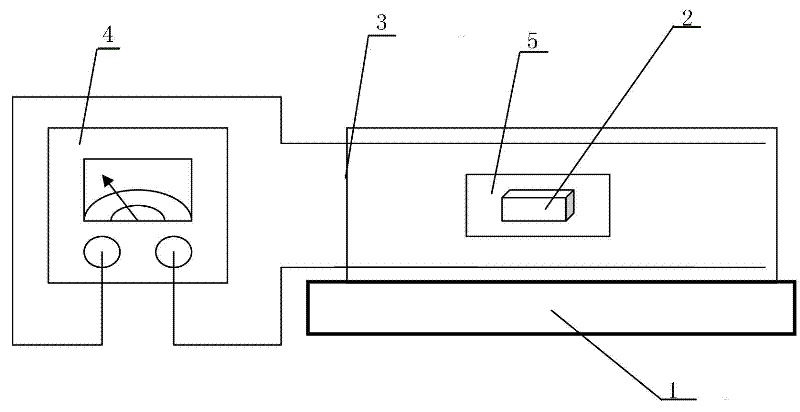

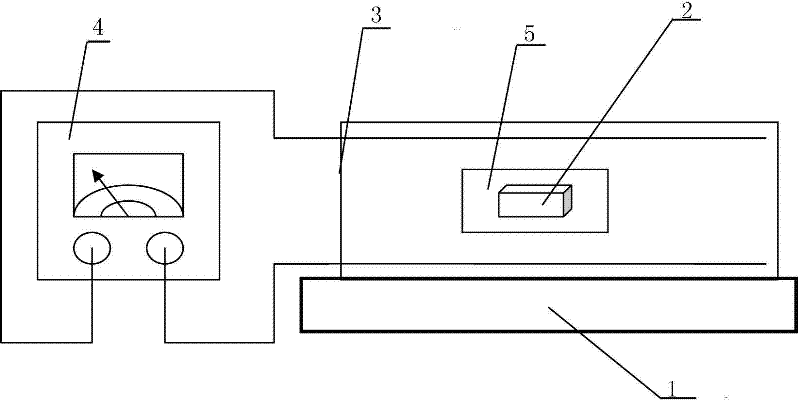

[0013] Such as figure 1 As shown, the structure of the present invention is: a device for measuring the vertical component of magnetic induction intensity, including an optical pump 2, a coil system 3 installed on a horizontal turntable 1, and a coil system 3 connected to a precision current source 4, through which the current source 4 gives The coil system 3 of the optical pump 2 is powered, and the probe of the optical pump 2 rotates in the uniform area 5 of the coil system. The coil system 3 adopts a square Helmhertz coil, a circular Helmhertz coil or a Galette coil. Other forms of field coils may also be used.

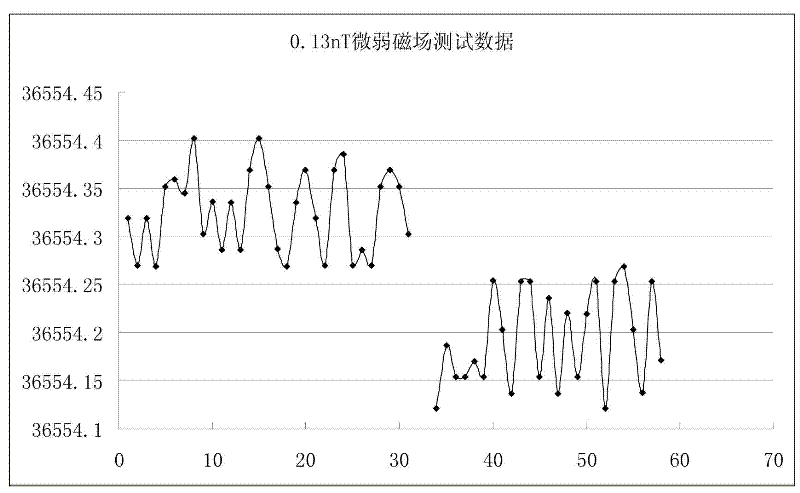

[0014] The working principle of the invention is as follows: the optical pump is used for high-sensitivity magnetic induction measurement, and the coil system is used for magnetic field compensation. To achieve high-sensitivity measurement of the vertical component, it is only necessary to compensate the horizontal component to the minimum value through the compe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com