A System for Automatically Generating NC Machining Codes

A technology of numerical control code and processing code, applied in general control system, control/regulation system, program control, etc., can solve the problem of not being able to adapt to the diversity of processing objects, limiting the rapid response of numerical control machine tools, and limiting the flexibility of numerical control codes, etc. problems, to achieve the effect of fast programming, high accuracy and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

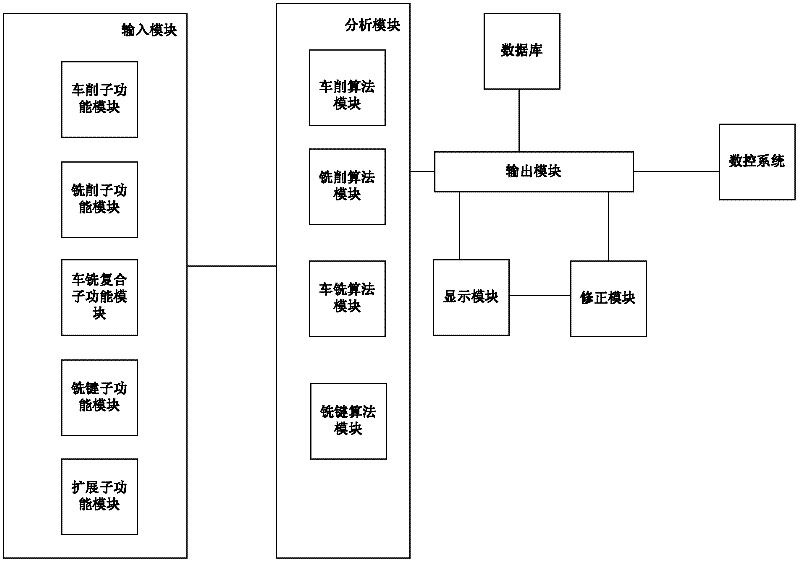

[0023] Attached below figure 1 Examples are also given to describe the present invention in detail.

[0024] The invention provides a system for automatically generating numerical control processing codes, comprising: an input module, an analysis module, a database, an output module, a display module and a correction module; wherein the input module is connected to the analysis module, the analysis module is connected to the output module, and the output module is connected to the output module. The database, the display module, the correction module and the numerical control system are respectively connected; the display module is connected to the correction module;

[0025] The input module includes turning sub-function module, milling sub-function module, turning-milling compound sub-function module, milling key slot sub-function module and extended sub-function module;

[0026] The analysis module includes turning algorithm module, milling algorithm module, turning and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com