Preparation method of sodium tungstate, method of collecting tungsten, device for preparing sodium tungstate, and preparation method of sodium tungstate aqueous solution

A technology of sodium tungstate and aqueous solution, which is applied in the preparation of tungsten compounds, chemical instruments and methods, tungsten oxide/tungsten hydroxide, etc., can solve the problem of not being able to obtain high-purity sodium tungstate aqueous solution, and achieve the effect of efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

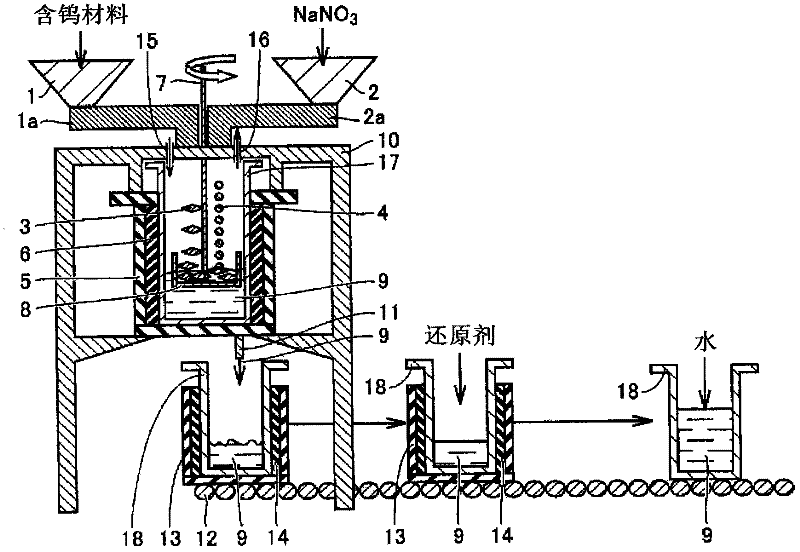

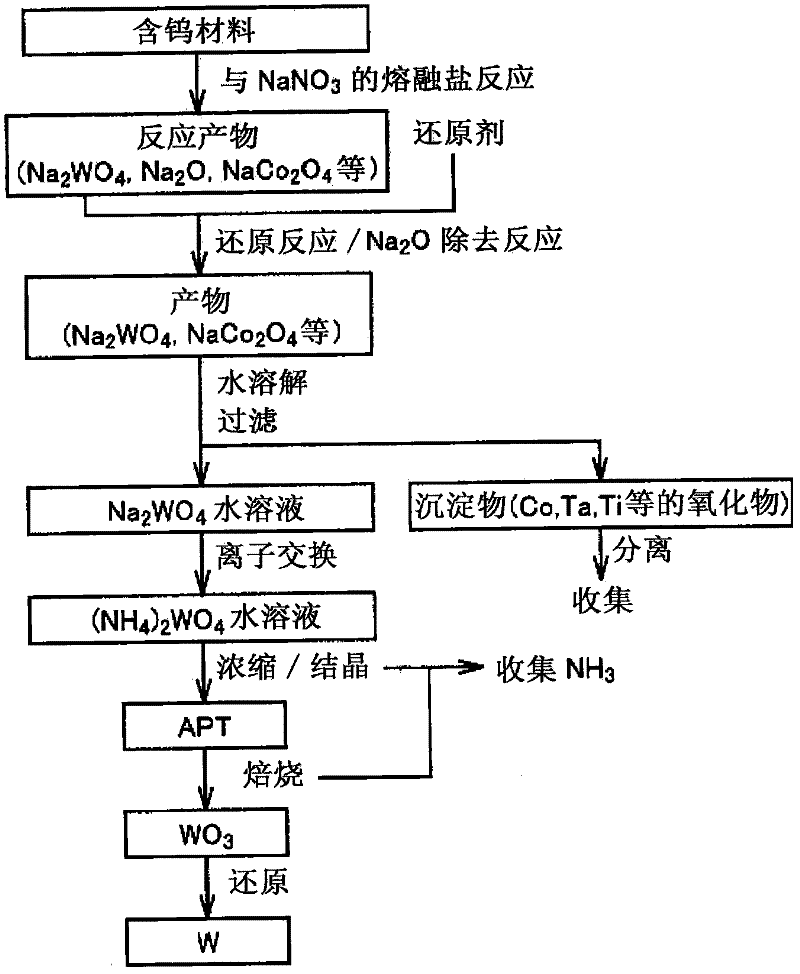

[0061] figure 1 is a schematic configuration diagram of an apparatus for preparing sodium tungstate according to the first embodiment, which is an example of an apparatus for preparing sodium tungstate used in the present invention. figure 1 The preparation device shown in includes the tungsten-containing material supply port 1 for supplying tungsten-containing material; the tungsten-containing material input pipe 1a connected with the tungsten-containing material supply port 1; the sodium nitrate supply port 2 for supplying sodium nitrate; and The sodium nitrate input pipe 2a connected to the sodium nitrate supply port 2; the outer wall part 10 connected with the tungsten-containing material input pipe 1a and the sodium nitrate input pipe 2a; the protective container 5 arranged inside the outer wall part 10; the outer wall part 10 arranged inside the protective container 5 Heating device 6; Be arranged in the reaction container 17 of heating device 6 inside; Pass through prot...

no. 2 approach

[0157] Figure 6 is a schematic configuration diagram of an apparatus for preparing sodium tungstate according to a second embodiment, wherein the apparatus is another example of an apparatus for preparing sodium tungstate used in the present invention. Figure 6 The production apparatus shown in is characterized by points (a) to (h) described below.

[0158] (a) As for the tungsten-containing material, a storage unit 1b capable of storing, for example, hundreds of kilograms of tungsten-containing material is provided above the tungsten-containing material supply port 1 . The tungsten-containing material is automatically supplied to the tungsten-containing material input pipe 1 a (such as a quantitative supply hopper) via a supply conveyor (not shown) and a tungsten-containing material supply port 1 . Therefore, the amount of tungsten-containing material to be dissolved can be increased to increase the productivity of sodium tungstate.

[0159] (b) For example, using a flexi...

no. 3 approach

[0171] Figure 7is a schematic configuration diagram of a device for preparing sodium tungstate according to a third embodiment, wherein the device is another example of the device for preparing sodium tungstate used in the present invention. Figure 7 The production apparatus shown in is characterized by adopting the following point (i) instead of the above-mentioned point (g) in the second embodiment.

[0172] (i) The melt 9 is discharged from the holding furnace 41 into the water dissolving tank 42 by means of a tilting mechanism. In other words, for example, the holding furnace 41 (the soft waste supply mechanism and the agitator are not shown) into which the soft waste material 25 and the soft waste material (calcined powder) have been introduced is separated from the soft waste material supply mechanism and the agitator and subsequently Such as Figure 8 tilted as shown in the schematic configuration diagram. This causes the melt 9 contained in the holding furnace 41 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| reaction rate constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com