Formula of crispy candies and preparation method

A production method and crisp technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of non-slippery taste, maintaining below 10%, and failing to obtain consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

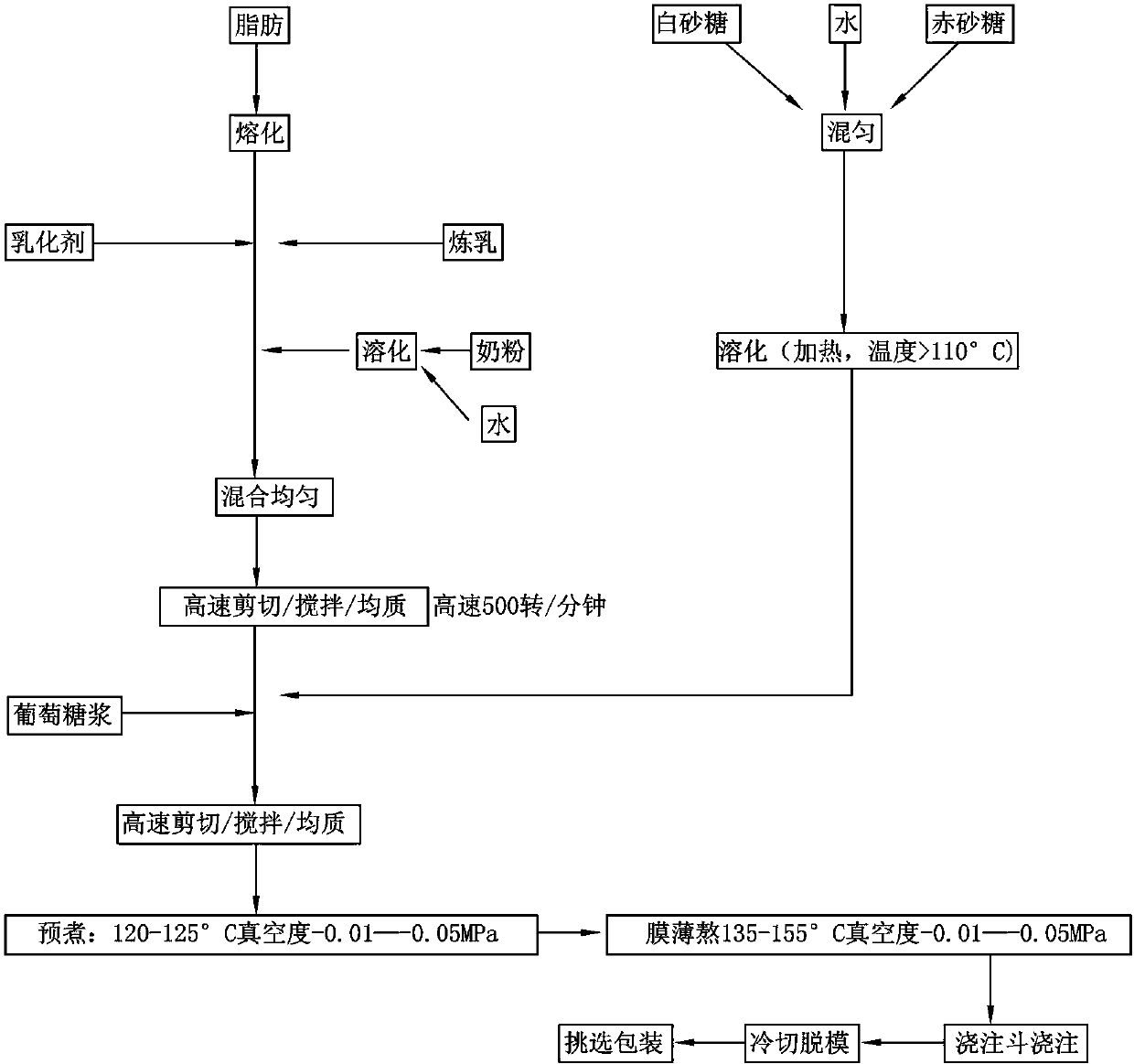

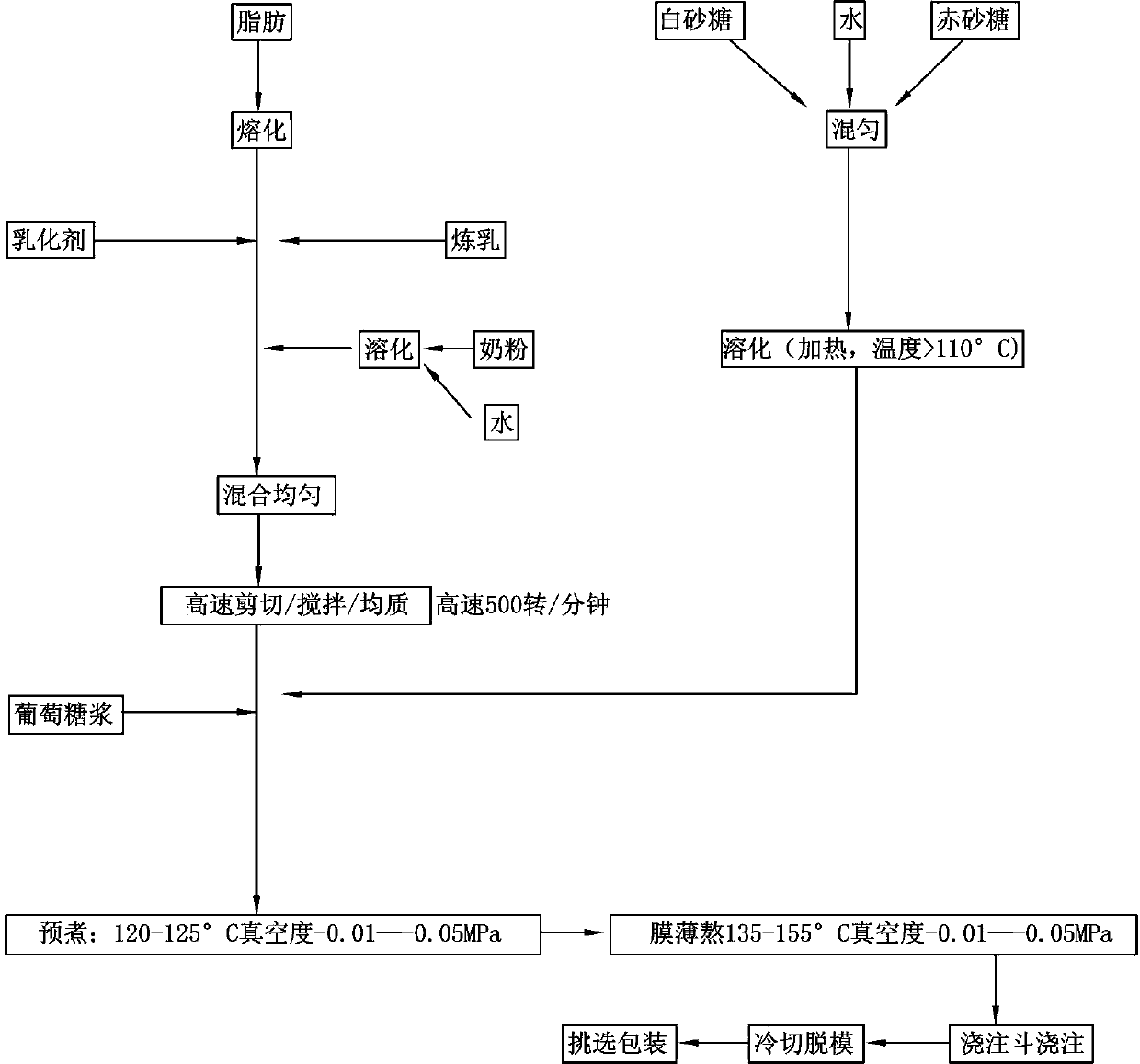

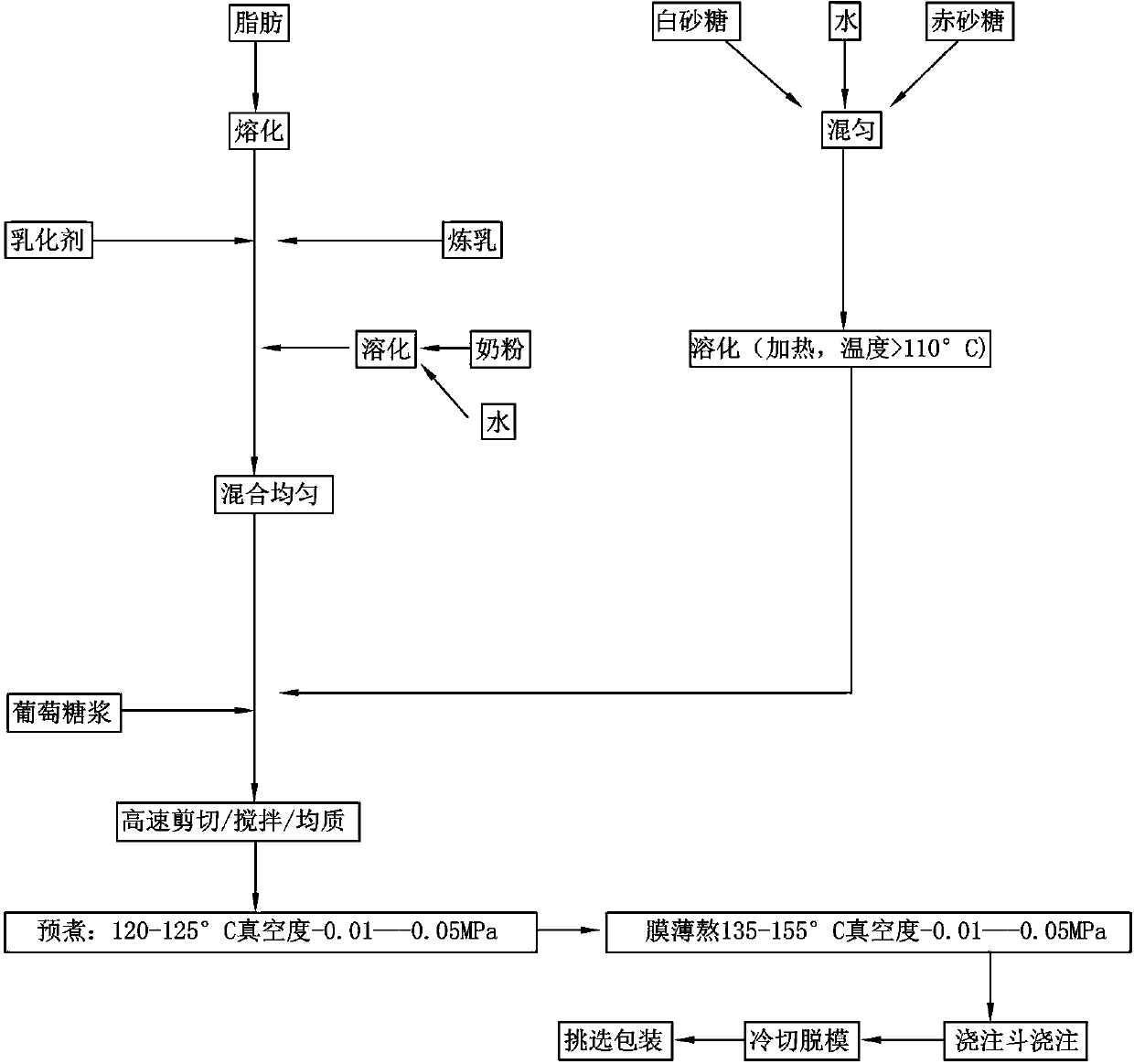

Method used

Image

Examples

Embodiment 1

[0061] 1. Crunchy sugar feeding formula

[0062] raw material

Dosage

White sugar

30%

brown sugar

0%

37%

Fat

25%

5%

2.5%

0.3%

Sucrose Fatty Acid Ester

0.1%

0.1%

0

0

[0063] The fat in the formula refers to all kinds of fats or fats in different proportions that can be used in food. Fat refers to one of: cocoa butter, cocoa butter substitute, hydrogenated or partially hydrogenated vegetable oil, peanut oil, soybean oil, etc.

[0064] Production Method:

[0065] A. Put 25KG of fat into a 60°C carburetor to melt the oil;

[0066] B. Put the melted oil into a high-speed stirring shear pot or a high-pressure homogenizer, add 0.3KG lecithin, 0.1KG sucrose fatty acid ester, 2.5KG condensed milk, and then stir at high speed ...

Embodiment 2

[0073] 2. Crunchy sugar feeding formula

[0074] raw material

Dosage

White sugar

30%

brown sugar

0%

42%

Fat

20%

5%

2.5%

0.3%

Sucrose Fatty Acid Ester

0.1%

0.1%

0

[0075] acidity regulator

0

[0076] The fat in the formula refers to all kinds of fats or fats in different proportions that can be used in food. Fat refers to one of: cocoa butter, cocoa butter substitute, hydrogenated or partially hydrogenated vegetable oil, peanut oil, soybean oil, etc.

[0077] Production Method:

[0078] A. Put 20KG of fat into a 60°C carburetor to melt the oil;

[0079] B. Put the melted oil into a high-speed stirring shear or high-pressure homogenizer, add 0.3KG lecithin, 0.1KG sucrose fatty acid ester, 2.5KG condensed milk, and then carry...

Embodiment 3

[0086] 3. Crunchy sugar feeding formula

[0087] raw material

Dosage

White sugar

20%

brown sugar

10%

32%

Fat

30%

5%

condensed milk

2.5%

0.3%

Sucrose Fatty Acid Ester

0.1%

0.1%

0

0

[0088] The fat in the formula refers to all kinds of fats or fats in different proportions that can be used in food. Fat refers to one of: cocoa butter, cocoa butter substitute, hydrogenated or partially hydrogenated vegetable oil, peanut oil, soybean oil, etc.

[0089] Production Method:

[0090] A. Put 30KG of fat into a 60°C carburetor to melt the oil;

[0091] B. Put the melted oil into the mixing pot, add 0.3KG lecithin, 0.1KG sucrose fatty acid ester, 2.5KG condensed milk and mix for 10 minutes. The temperature of the feed liquid is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com