Blowing silencing tube

A technology of silencer pipe and silencer cotton, which is applied in the field of injection system and an auxiliary device of dust collector injection system, which can solve the problems of blasting noise, loud noise of dust collector, uneven cleaning of dust on the surface of bag, and achieve rapid expansion , Reduce the effect of blowing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

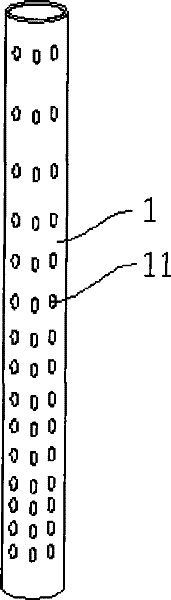

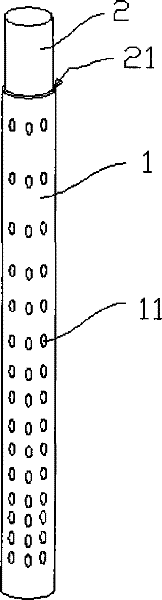

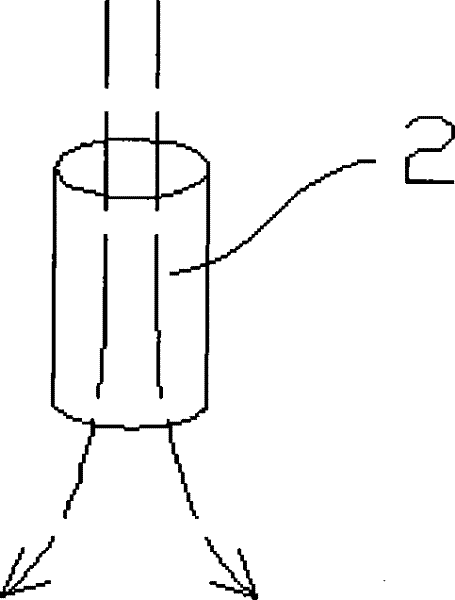

[0016] exist figure 1 In the shown embodiment, the blowing muffler pipe includes a metal pipe 1, and the metal pipe 1 is provided with ventilation holes 11 around its side from top to bottom, and the total area of the ventilation holes 11 is the nozzle port. 1-3 times the area.

[0017] In the above-mentioned blowing muffler pipe, the ventilation holes 11 are distributed from sparse to dense on the surface of the metal pipe 1 from top to bottom, which conforms to the distribution characteristics of the pressure of the high-pressure gas from the upper part to the lower part of the metal pipe 1, from high to low, Make the exhaust volume of the upper side of the metal pipe 1 equivalent to the exhaust volume of the lower side.

[0018] In the above-mentioned blowing silencer pipe, the surface of the metal pipe 1 is covered with sound-absorbing cotton (not shown),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com