High-efficiency and accurate grooving boring bar and grooving method

A boring bar and grooving technology, applied in the direction of boring bars, etc., can solve problems such as inconvenient operation, low efficiency, and unsafety, and achieve the effects of easy operation, high precision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

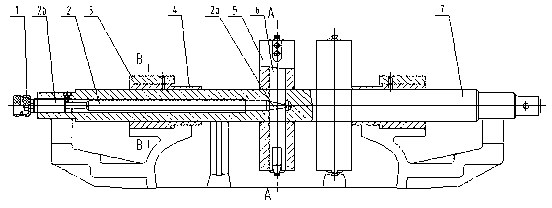

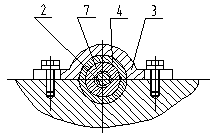

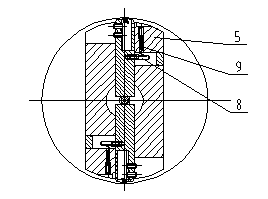

[0018] As shown in the figure, an efficient and accurate grooving boring bar includes a boring bar 7 connected to the power head at one end, a boring sleeve 4 set outside the boring bar, a boring disc 5 installed in the middle of the boring bar, and a boring disc installed The cutting knife 6 inside the boring bar is provided with a push rod coaxial with the boring bar and facing the cutting knife 6 in the middle of the boring bar. The bottom end of the cutting knife extends to the inside of the boring bar until it contacts the top cone , the top 2a of the ejector rod against the cutter is conical, and the outer end of the ejector rod 2 is located at the outer end of the boring bar. Such as image 3 As shown, a horizontal reset lever 8 is provided on the side of the cutter body of the cutter, and a longitudinal through hole leading to the reset lever is provided at the top of the boring cutter disc 5, and a reset spring 9 that promotes the reset of the cutter is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com