Tool for disassembling and assembling shaft pins

A shaft pin and tool technology, which is applied in the field of disassembling and assembling shaft pin tools, can solve the problems of affecting the shaft installation accuracy, loosening the shaft, accidentally injuring other parts, etc., and achieves the effects of improving work efficiency, quick removal, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

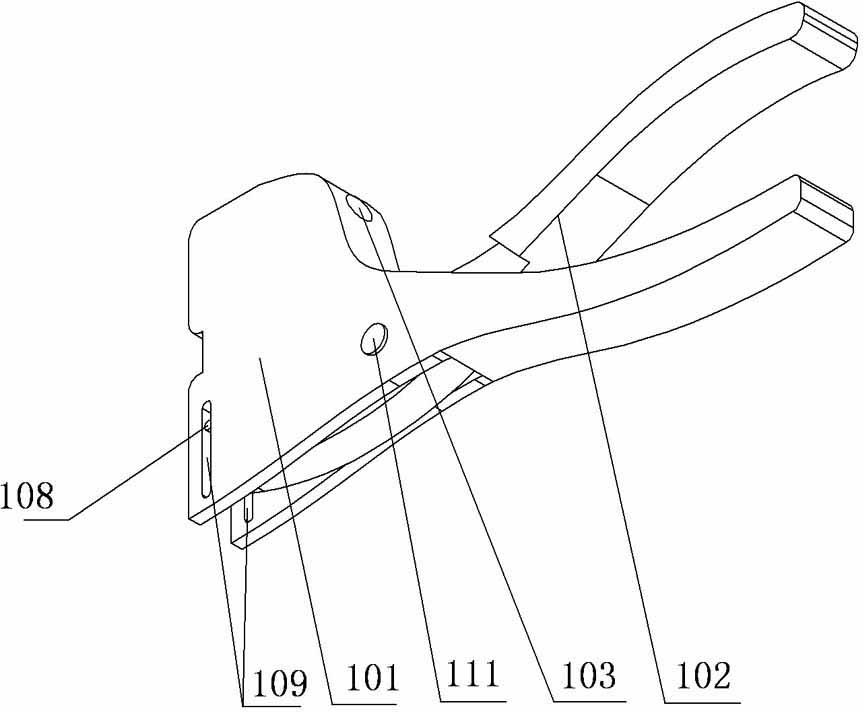

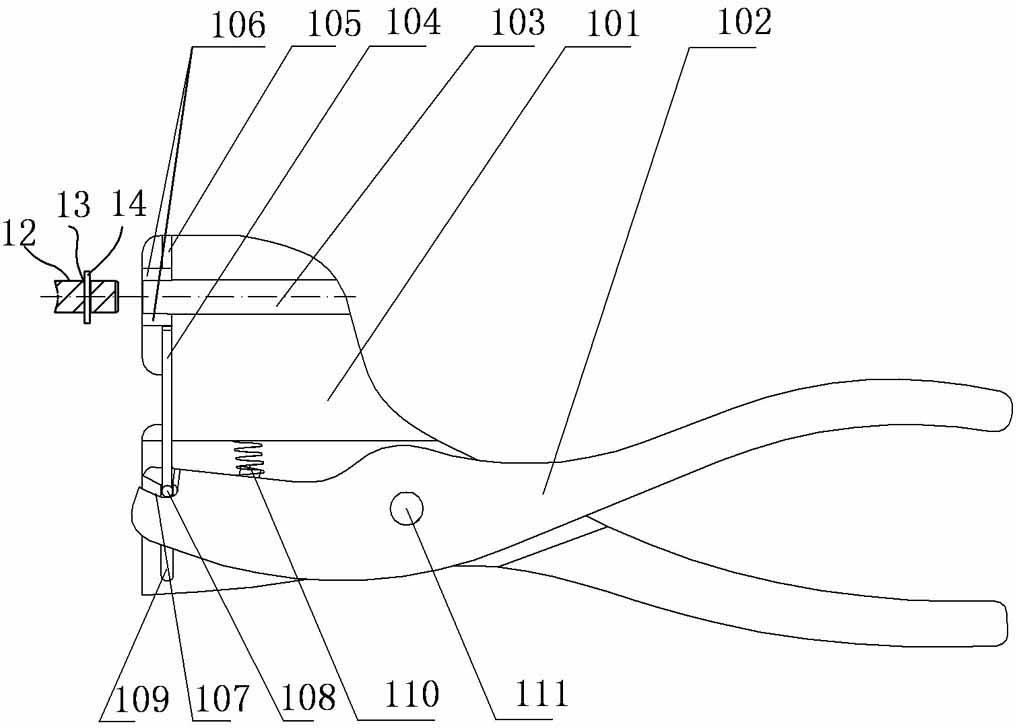

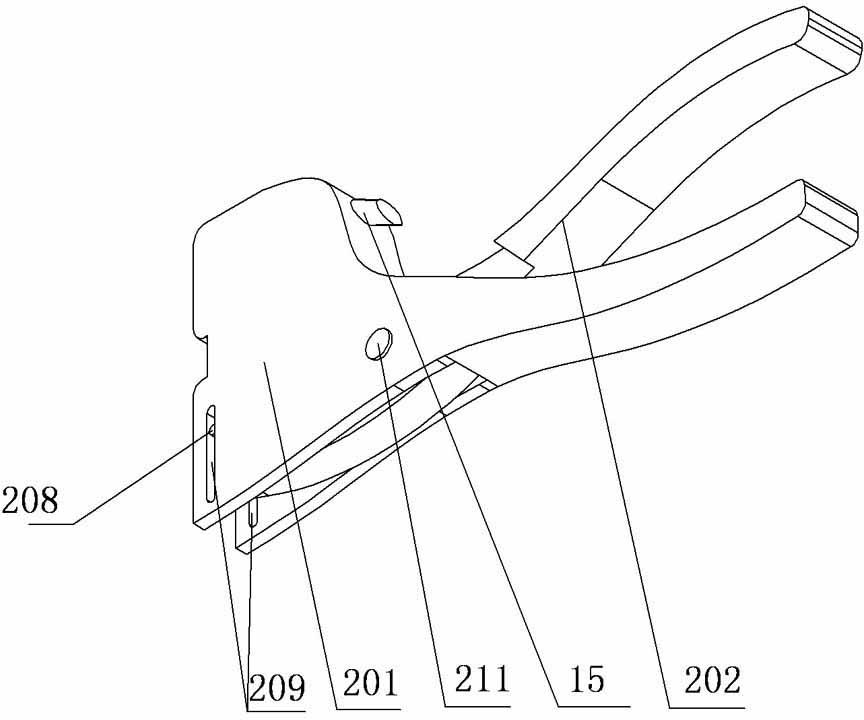

[0027] Such as figure 1 , figure 2 and Figure 5 as shown,

[0028] The shaft pin removal pliers of the shaft pin removal tool of the present invention include a first pliers body 101 and a first handle 102 hinged to the first pliers body 101, and a first through guide is provided on the head of the first pliers body 101. Hole 105, a first push rod 104 is fitted with clearance in the first guide hole 105, the diameter of the first push rod 104 is smaller than the inner diameter of the shaft pin mounting hole 13 of the shaft pin 14 to be removed, and the first push rod One end of 104 is hinged with the head of the first handle 102; the head of the first pliers body 101 is provided with a first through hole 103 that opens outward and inserts the shaft 12 of the shaft pin 14 to be removed, the first through hole The axis of 103 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com