Prestressed concrete tubular pile locking mechanical quick joint

A concrete pipe pile and prestressing technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of time-consuming and labor-intensive welding, long downtime of the pile driver, affecting the working efficiency of the piling machine, etc., so as to improve the work efficiency. , docking fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

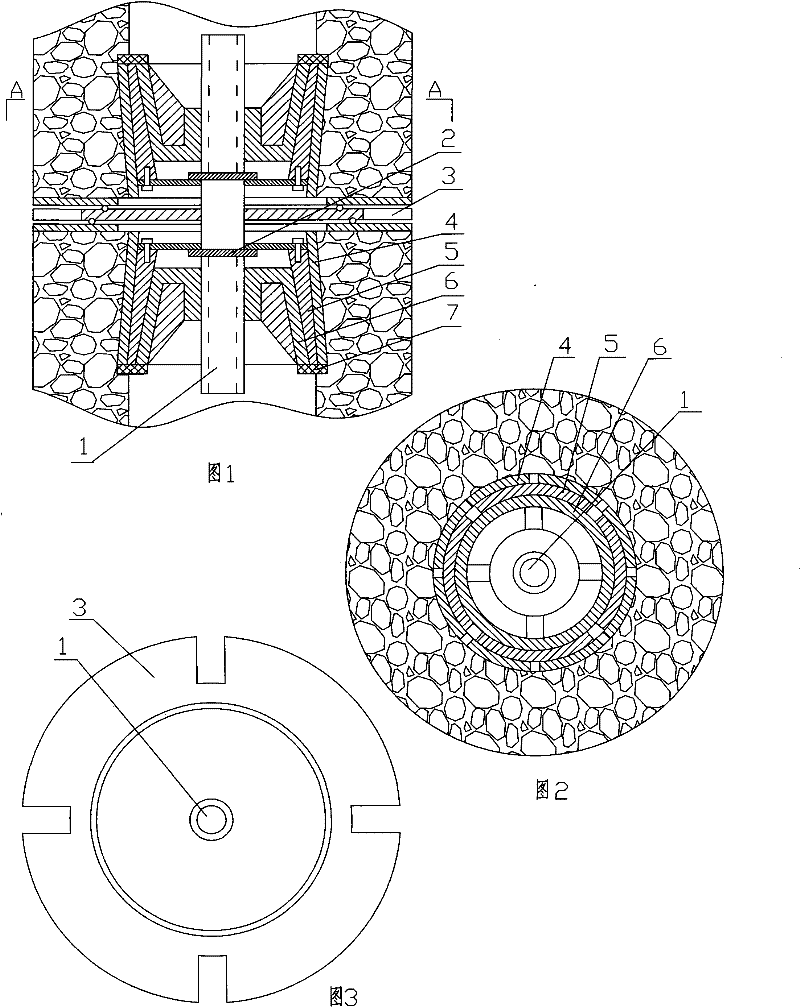

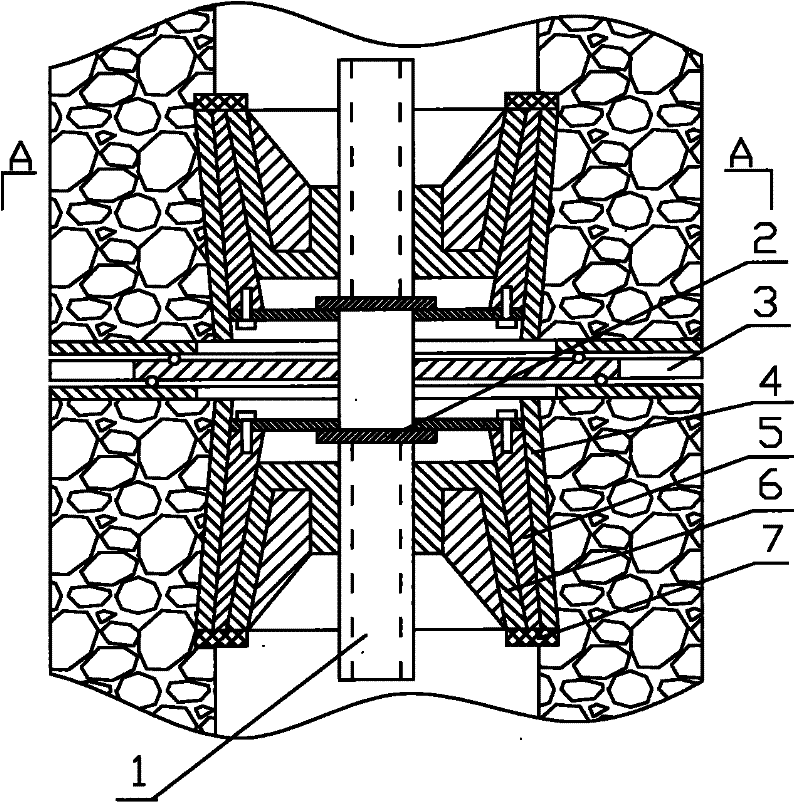

[0009] The invention includes pipe piles, which are characterized in that: the inner holes at both ends of the pipe piles are provided with stepped taper holes whose outer ports are smaller than the diameter of the inner bottom circle; A connecting device composed of a fan-shaped cone pad, a double-ended screw, and a locking turntable 3; the expanding cone ring 4 is a tubular body, and several axial long strip grooves are evenly distributed on the tubular body, and the outer diameter of the tubular body is smaller than the taper hole of the pipe pile step. The diameter of the outer port; the cone expansion plug 6 is in the shape of a frustum, the axial height of the cone is less than the axial height of the expansion ring 4, the major diameter of the outer circle of the cone is smaller than the inner diameter of the expansion ring 4, and there is a threaded hole in the center of the cone, two The threads of the taper tapped holes are opposite to each other; the large-diameter e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com