Vertical shaft construction method under unfavorable geological condition

A technology of geological conditions and construction methods, applied in shaft equipment, sinking, earthwork drilling and mining, etc., can solve problems such as low strength, difficulty in organizing construction, and affecting the construction progress of hydropower stations, etc., and achieve the effect of strong promotion and reduction of landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above-mentioned technical solutions and advantages of the present invention can be easily understood from the detailed descriptions and accompanying drawings of the following selected embodiments.

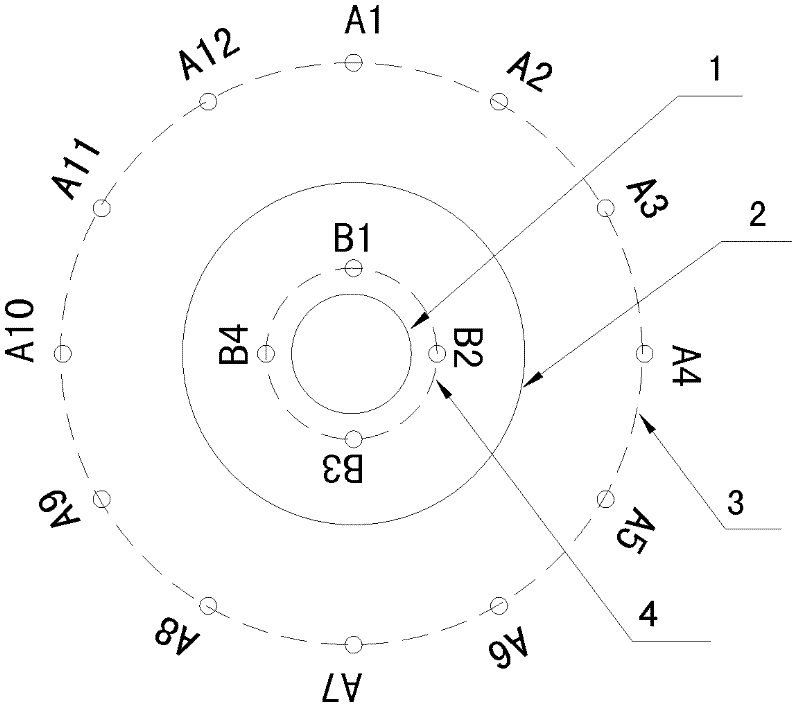

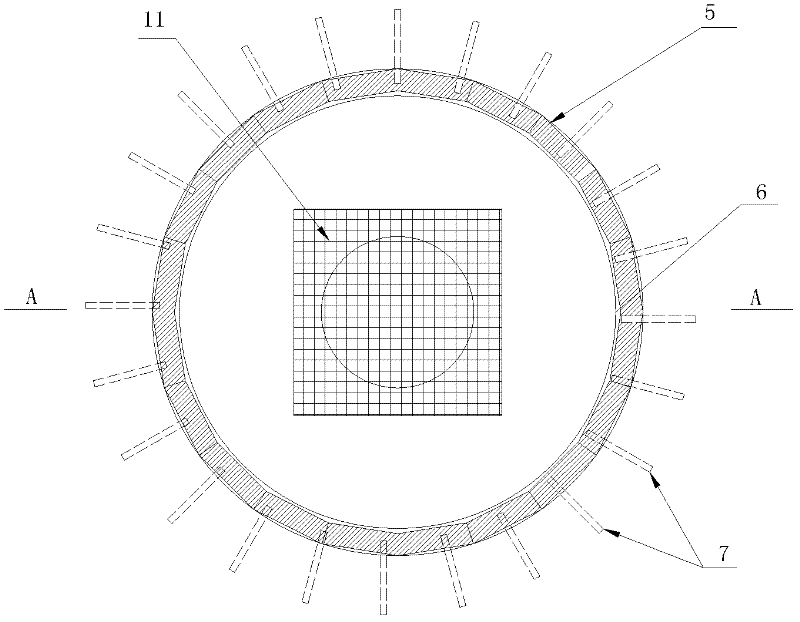

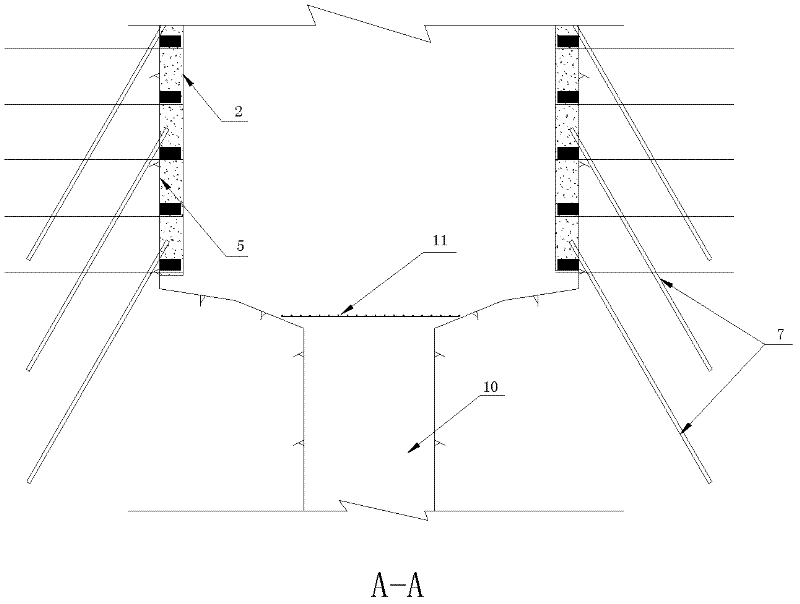

[0031] The shaft construction method under this unfavorable geological condition includes the following construction steps: the first step: pouring cover weight concrete at the position of the shaft wellhead; the second step: arranging two circles of pre-consolidated grouting holes on the cover weight concrete, The anchor tendon is set inside, the depth of the grouting hole is the depth of the shaft, and the depth of the anchor tendon is the same as the depth of the grouting hole; the third step: use the raise drilling machine to drill the guide hole of the vertical shaft from top to bottom; the fourth step: use the reverse shaft The well drilling rig drills the guide shaft 10 from bottom to top; the fifth step: advance support before the expansion; the sixth step: the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com