Construction method for ultra-deep foundation pit non-drainage earth excavation

A technology of earthwork excavation and construction method, which is applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of waste of groundwater resources, inrush of confined water, etc., and achieve the effects of saving construction costs, reducing landslides, and reducing the degree of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

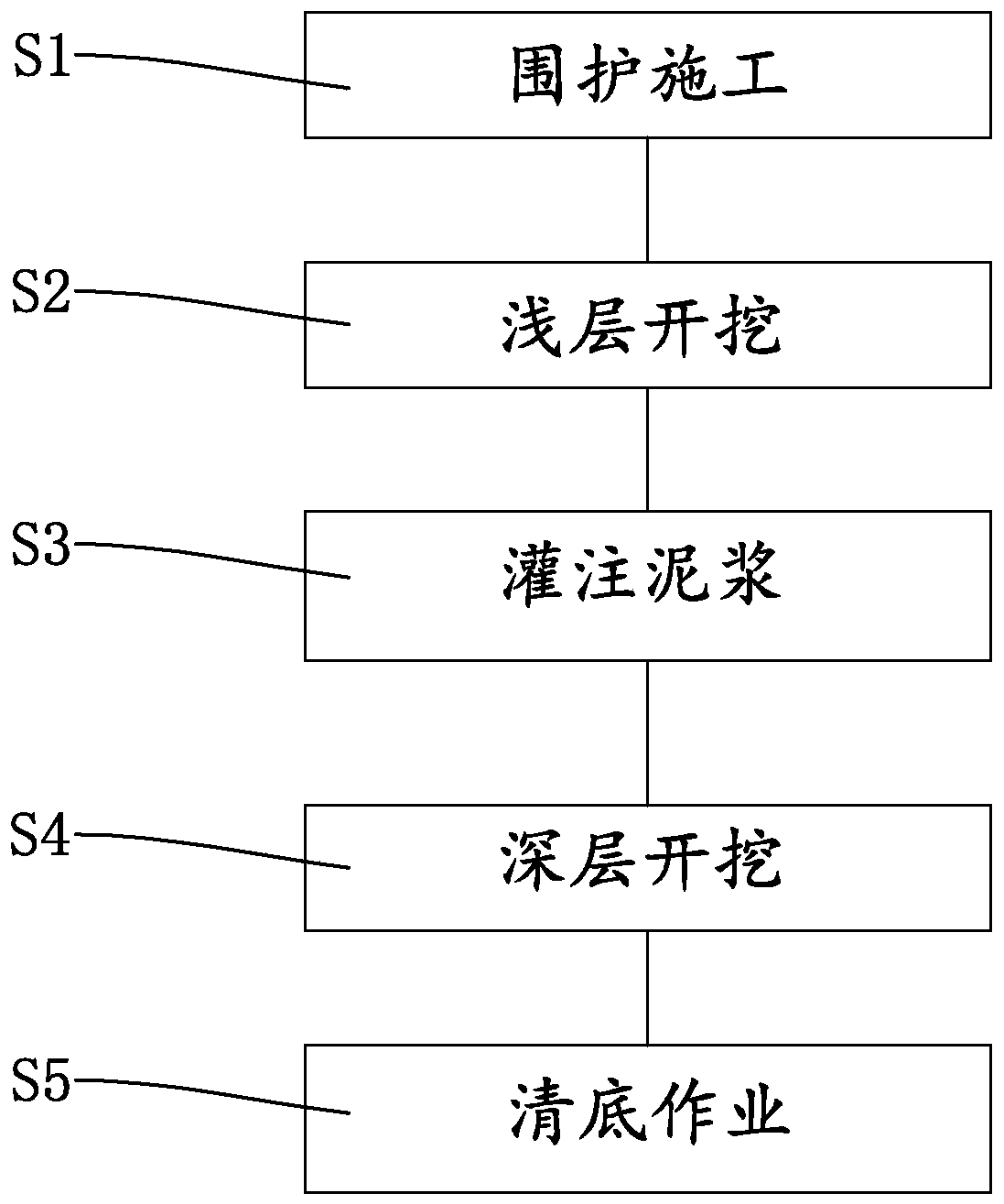

[0039] See attached figure 1 , a construction method for undrained earthwork excavation of an ultra-deep foundation pit, comprising the following steps,

[0040] The construction site is pre-arranged, the construction site is cleaned up, and infrastructure such as mud mixing tank 5 and sedimentation tank 6 are set up around the side of the foundation pit to be excavated.

[0041] S1, enclosure construction, enclosure construction is carried out on the 1st surrounding side of the foundation pit to be excavated;

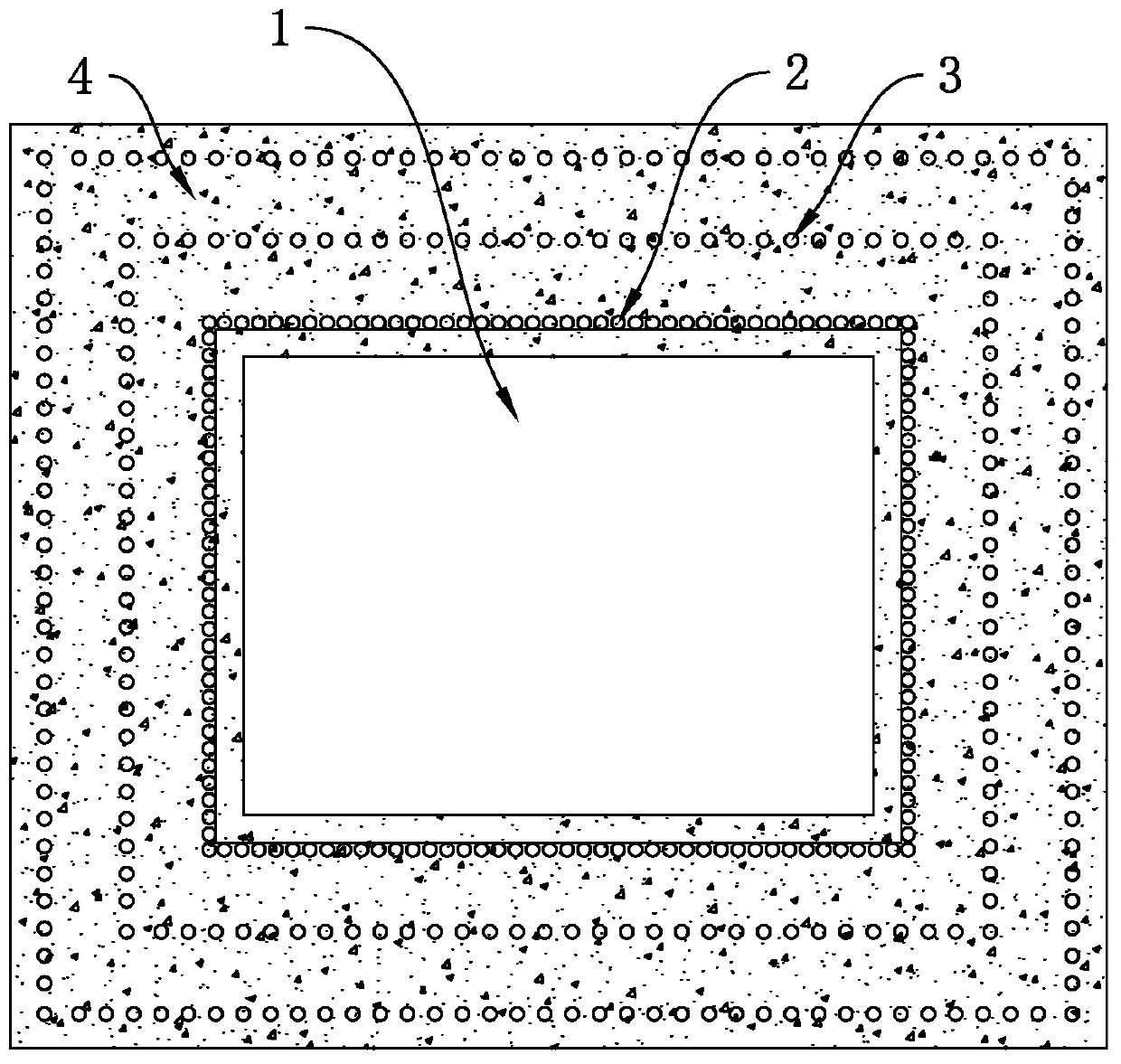

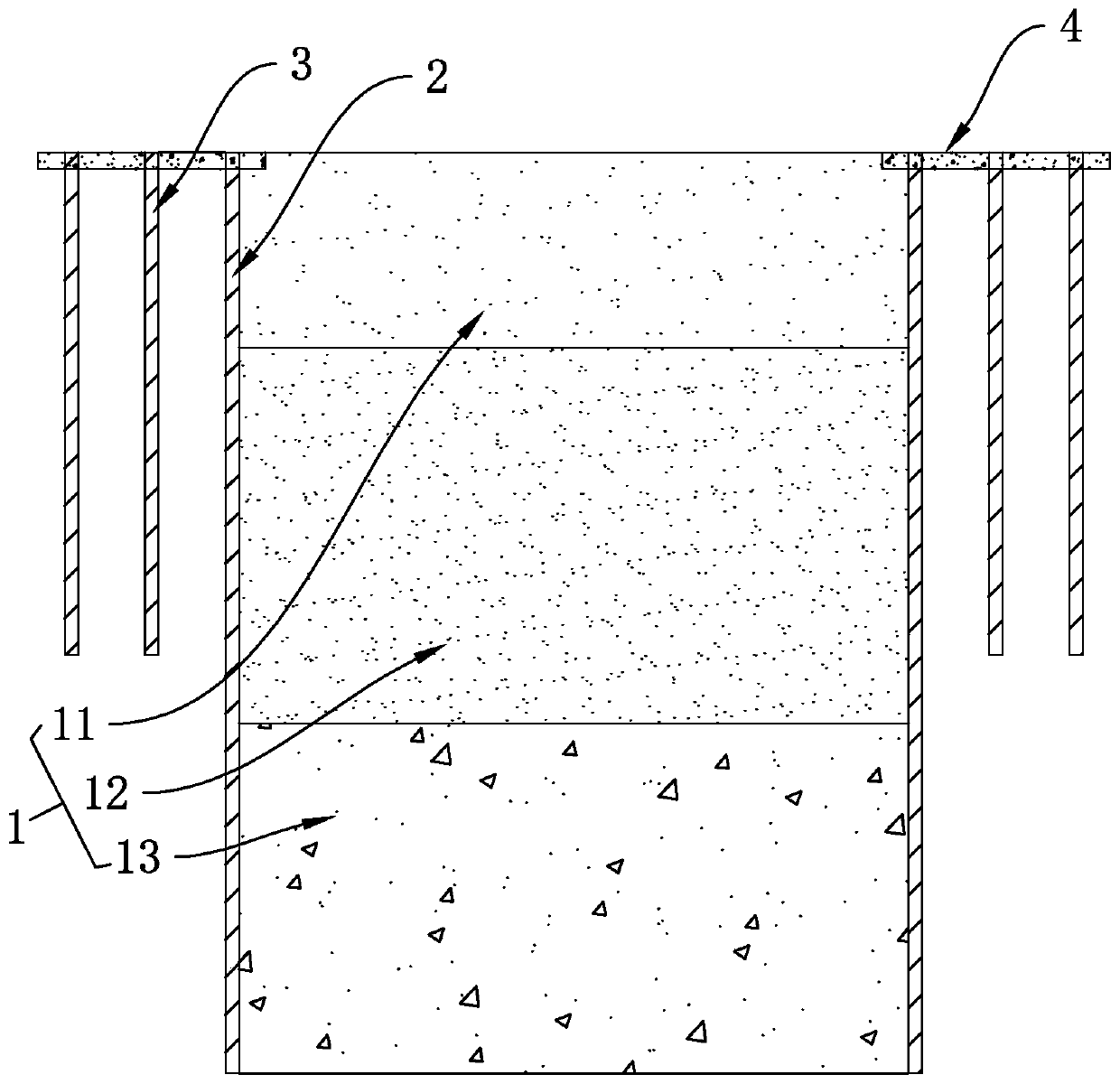

[0042] S1.1, (see figure 2 with image 3) Set up several first pipe piles 2 on the ground around the foundation pit 1 to be excavated, and the insertion depth of the first pipe pile 2 enclosure is 1.2-1.5 times, preferably 1.5 times, the excavation depth; any adjacent The two pipe piles are placed close to each other, and the first pipe piles 2 are evenly inserted and set on the ground around the foundation pit 1 to be excavated to form a first surrounding pile fen...

Embodiment 2

[0054] A construction method for undrained earthwork excavation of an ultra-deep foundation pit, which differs from Implementation 1 in that:

[0055] S1, enclosure construction, enclosure construction is carried out on the 1st surrounding side of the foundation pit to be excavated;

[0056] S1.1. The type of enclosure can be any one of underground diaphragm wall, bored pile row, steel pipe pile row, SMW pile row, precast concrete sheet pile retaining wall, steel sheet pile, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com