Dehumidifying and dust-removing method

A dust removal device and humidity technology, which is applied in the direction of heating methods, lighting and heating equipment, heating and ventilation control systems, etc., can solve the problem of not being able to understand the dust concentration and humidity values of the air environment in the computer room, not being able to take into account both dust removal and dehumidification, and not being able to automatically control Start and stop problems of dust collector and dehumidifier to achieve efficient dehumidification and dust removal, reduce occupied space, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

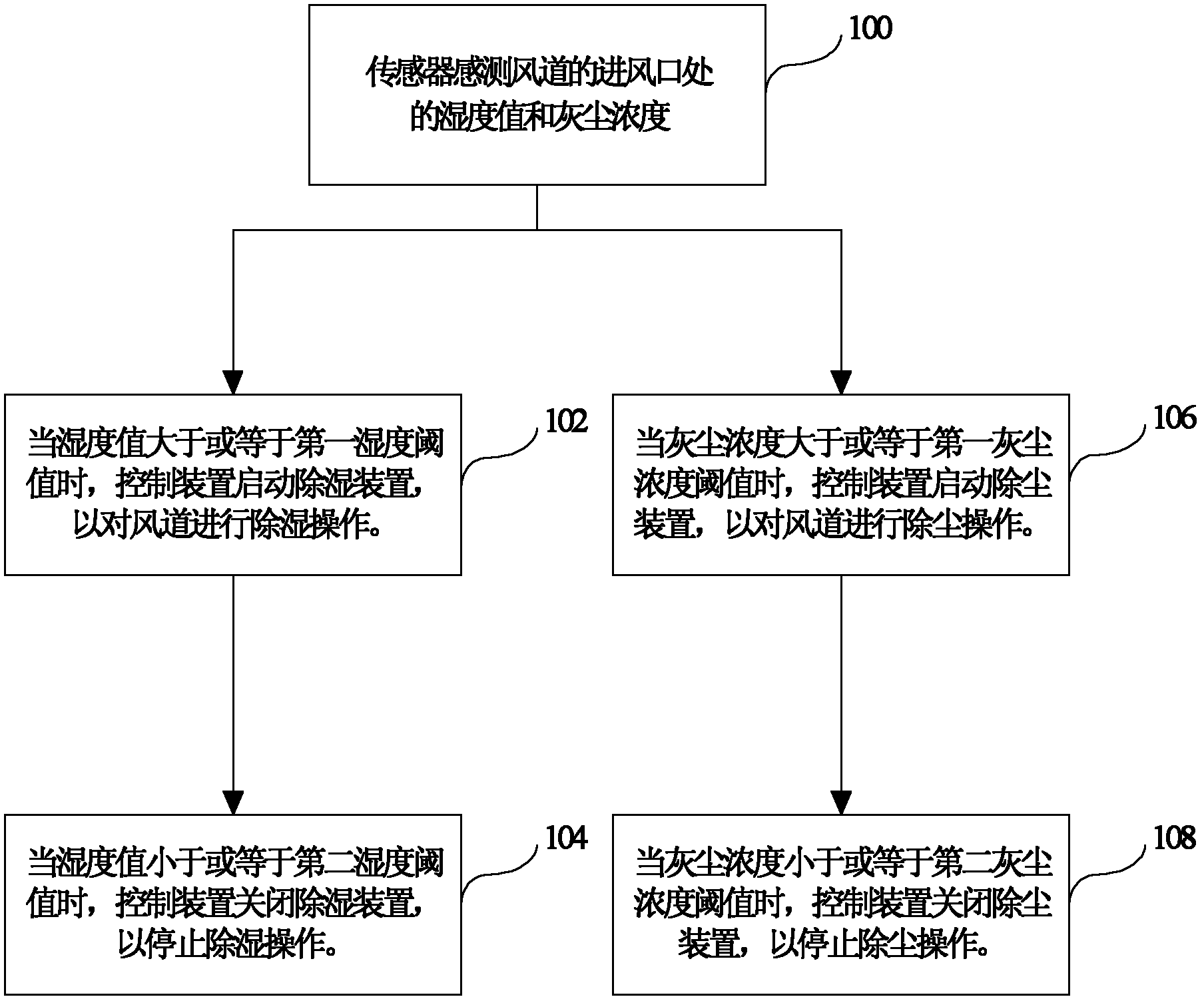

[0028] figure 1 It is an overall flowchart of the dust removal method according to the embodiment of the present invention.

[0029] Step S100: the sensor senses the humidity value and the dust concentration at the air inlet of the air duct.

[0030] The humidity value is the relative humidity value, which is the ratio of the absolute humidity of the humid air to the maximum absolute humidity that may be reached at the same temperature, or the ratio of the partial pressure of water vapor in the humid air to the saturation pressure of water at the same temperature. The sensor is a relative humidity sensor, which is arranged at the air inlet of the air duct, and sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com