Quick separating high-current circular electrical connector

An electrical connector, high current technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., to achieve excellent contact performance and solve the effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

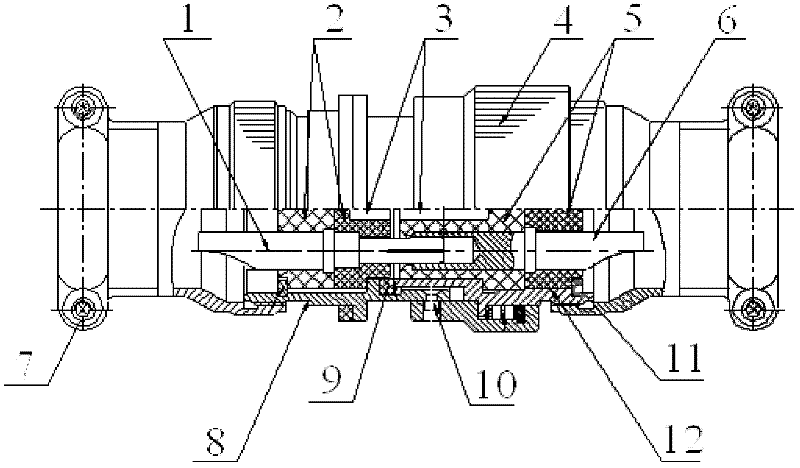

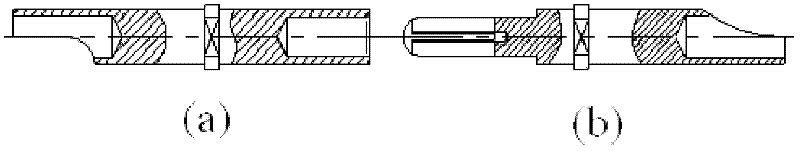

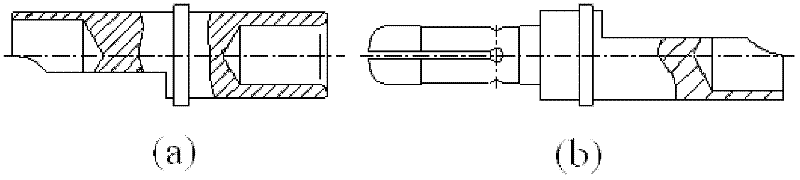

[0023] see figure 1 , a quick-disconnect high-current circular electrical connector, including a plug and a socket, the plug includes a front mounting plate, a rear mounting plate 2, and a plurality of mounting holes 3 are respectively provided on the front mounting plate and the rear mounting plate 2, each A positioning step is installed in the installation hole, and the pin plug or jack plug 1 is also provided with a positioning step. The pin plug or jack plug 1 is clamped and fixed between the front mounting plate and the rear mounting plate 2 and potted in the middle Put the silicone rubber into the plug housing 8; the rear end of the plug housing 8 is screwed with a grommet 11, and the rear end of the grommet 11 is equipped with a cable clamp 7;

[0024] The socket includes a front mounting plate and a rear mounting plate 5. The front mounting plate and the rear mounting plate 5 are respectively provided with a plurality of mounting holes, positioning steps are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com