Coffee bean grinder and coffeemaker with same

A grinding machine, coffee bean technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of complex design structure, occupation, and the reduction of the number of coffee powders, to simplify product structure, reduce manufacturing costs, and cleanability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

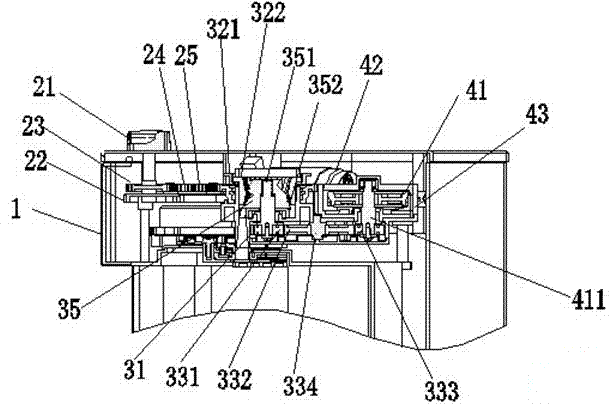

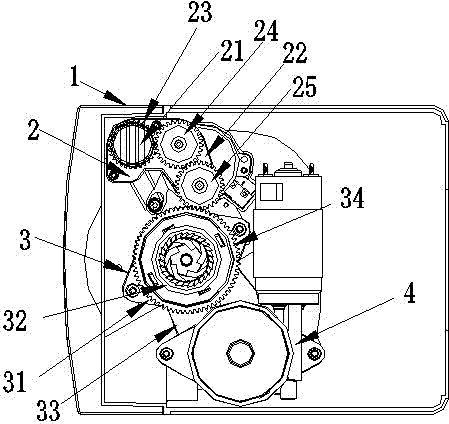

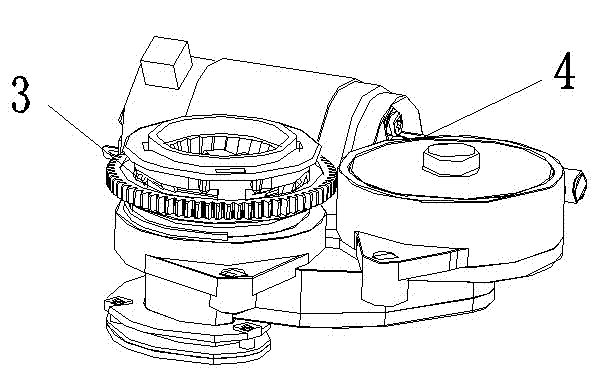

[0023] Such as Figure 1 to Figure 9 The shown coffee bean grinder includes a body 1, a coffee powder grinding device 3, a driving device 4 and a transmission device 33, wherein the coffee powder grinding device 3 is arranged in the grinding chamber 31 on the body 1 and includes an outer grinding assembly 32 and The inner grinding assembly 35 and the outer grinding assembly 32 are located above the inner grinding assembly 35 and have a certain distance from the inner grinding assembly 35. The driving device 4 drives the inner grinding assembly 35 in the grinding chamber 31 to rotate through the transmission device 33, and the coffee beans are inside Coffee powder is ground between the grinding assembly 35 and the outer grinding assembly 32 . Such as Figure 5 As shown, the outer grinding assembly 32 includes an outer grinding wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com