Method for Improving Hydrophilicity of Polyester Forming Net and Polyester Forming Net

A hydrophilic polymer, forming wire technology, applied in the direction of heating/cooling fabrics, textiles and paper making, paper making machines, etc., can solve problems such as difficulty in cleaning, and achieve the effects of low cost, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

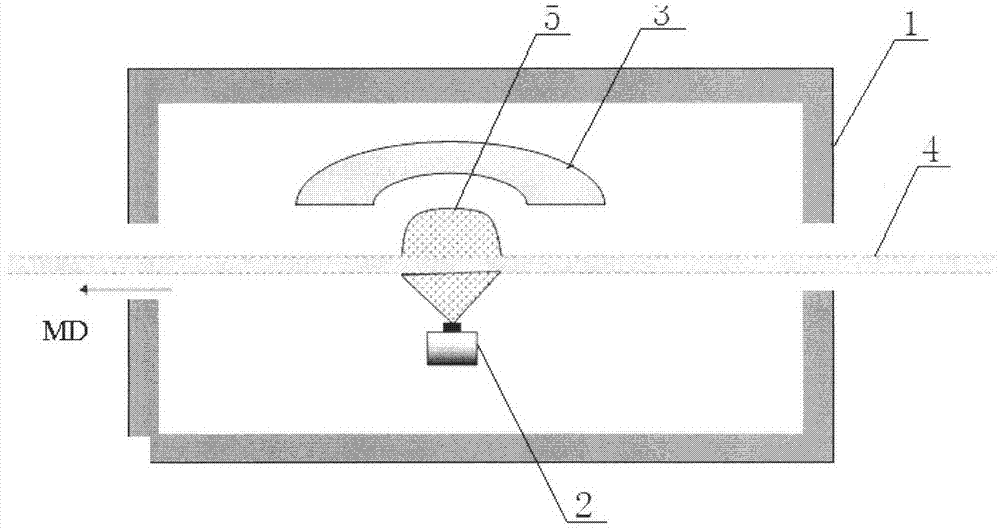

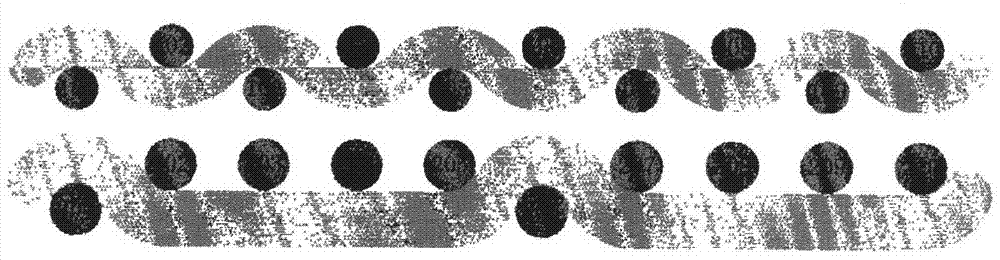

[0026] see figure 1 , figure 2 , image 3 and Figure 4, the existing polyester forming net used in this method of improving the surface hydrophilicity of the polyester forming net, such as the warp polyester raw yarn after warping, passes through the loom and weft polyester monofilament, and at the same time the bottom weft is matched with a certain proportion Nylon monofilament is woven into a three-layer net, that is, the existing polyester three-layer forming net 4, and its weaving structure is 16 sheds, 20 sheds or 24 sheds, and 16 sheds are used in the present embodiment; first, a section of heat setting: about to The above prepared polyester three-layer forming 4 net slowly passes through the hot air circulation heating machine 1 along the machine direction, and is heated to 190°C; at the same time, it is sprayed with a spray coating set in the hot air circulation heating machine 1 and located below the polyester forming net 4 Machine 2 atomizes a cationic polyacryl...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, and the similarities will not be described in detail. The difference is: in this example, in a heat setting process, the polyester three-layer forming net is heated to 180°C; at the same time, the concentration of the cationic polyacrylamide solution is 10%, the temperature is 160°C, and the molecular weight is 500,000; During the second heat setting process, the polyester three-layer forming wire was heated to 140°C. The microstructure of its surface charge before and after coating modification can be found in image 3 and Figure 4 .

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 1, and the similarities will not be described in detail. The difference is: in this example, in a heat setting process, the polyester three-layer forming net is heated to 200°C; at the same time, the concentration of the cationic polyacrylamide solution is 15%, the temperature is 160°C, and the molecular weight is 1.5 million; During the second heat setting process, the polyester three-layer forming wire was heated to 140°C. The microstructure of its surface charge before and after coating modification can be found in image 3 and Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com