Anti-blocking cylindrical classifying screen

A grading screen and cylinder technology, applied in the field of grading screen, can solve the problems of increased labor intensity, troublesome and inconsistent screening process, and achieve the effect of preventing the screen from being blocked, improving work efficiency and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

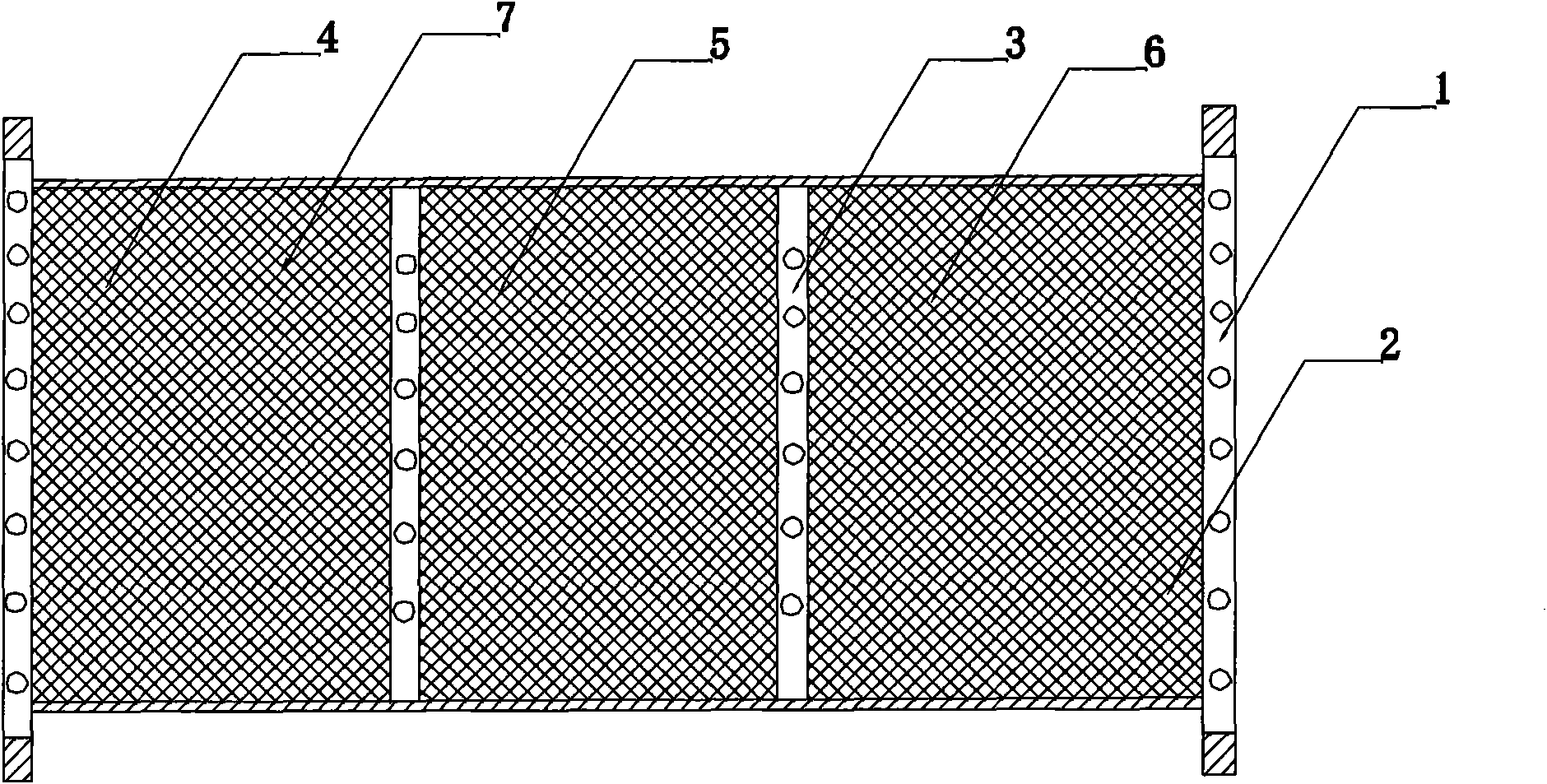

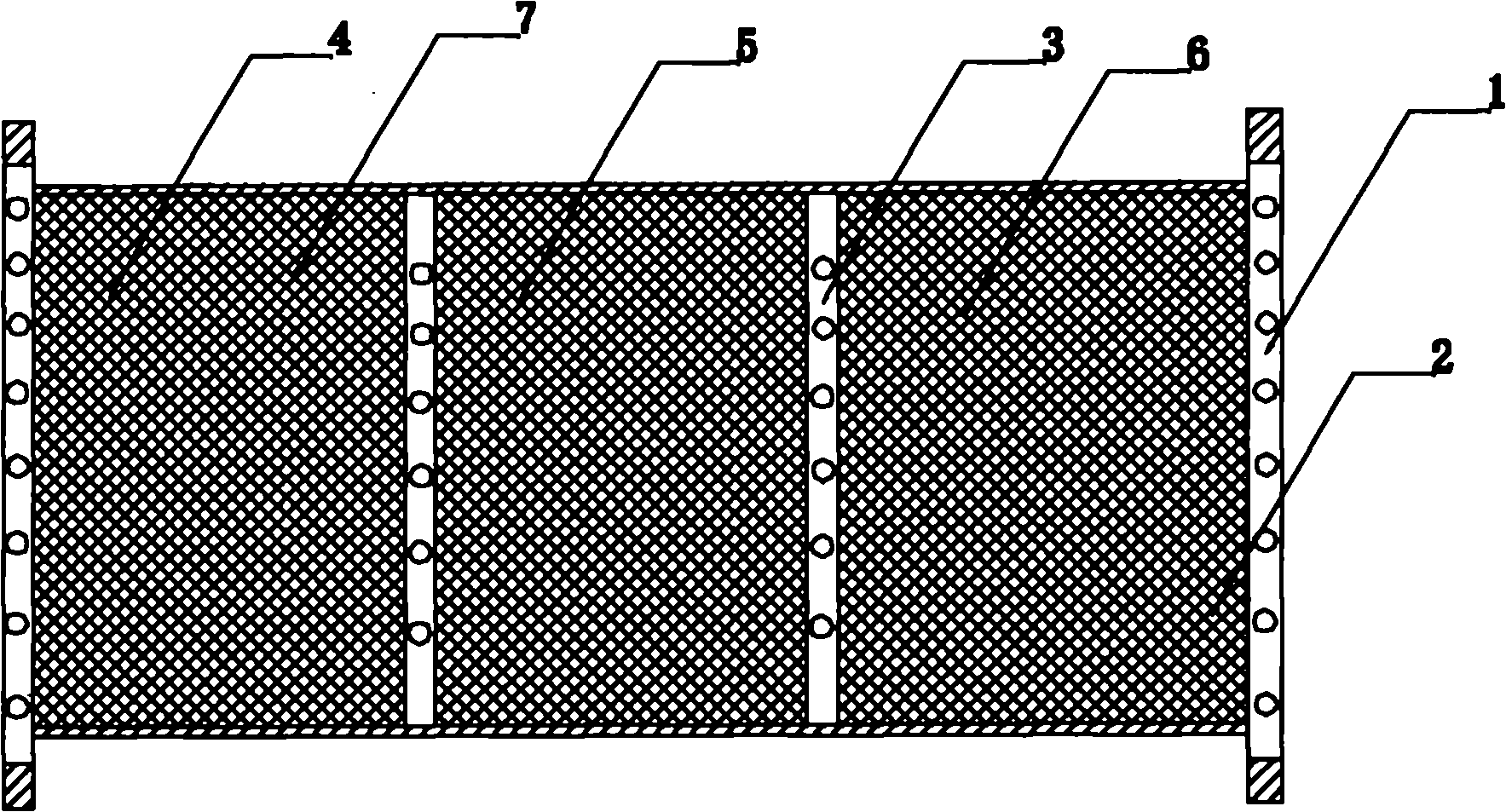

[0011] Such as figure 1 As shown, an anti-blocking cylindrical grading screen includes two cylindrical frames 1 arranged parallel to each other and a screen 2 fixed between the two cylindrical frames 1. In the screen 2 between the two cylindrical frames 1 There are two ribs 3, and each rib 3 is set parallel to the cylindrical frame 1. The front cylindrical frame 1 and the adjacent ribs 3 form a primary screen area 4, and the rear cylindrical frame 1 The third-level screen area 6 is formed between the 3 adjacent ribs, and the second-level screen area 5 is formed between the two ribs. The screen cloth 2 on each level of screen area is interwoven with elastic screen bars 7 such as steel wire bars, rubber bars or polyurethane bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com