Stamping edging device without need of manual polishing

A technology that does not require labor and pressurization devices. It is applied in the field of auto parts production. It can solve the problems of high labor intensity, low production efficiency, and difficult collection of aluminum chips, and achieve the effect of reducing quantity and labor intensity and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The stamping and edging device without manual grinding provided by the present invention will be described in detail below in conjunction with specific embodiments.

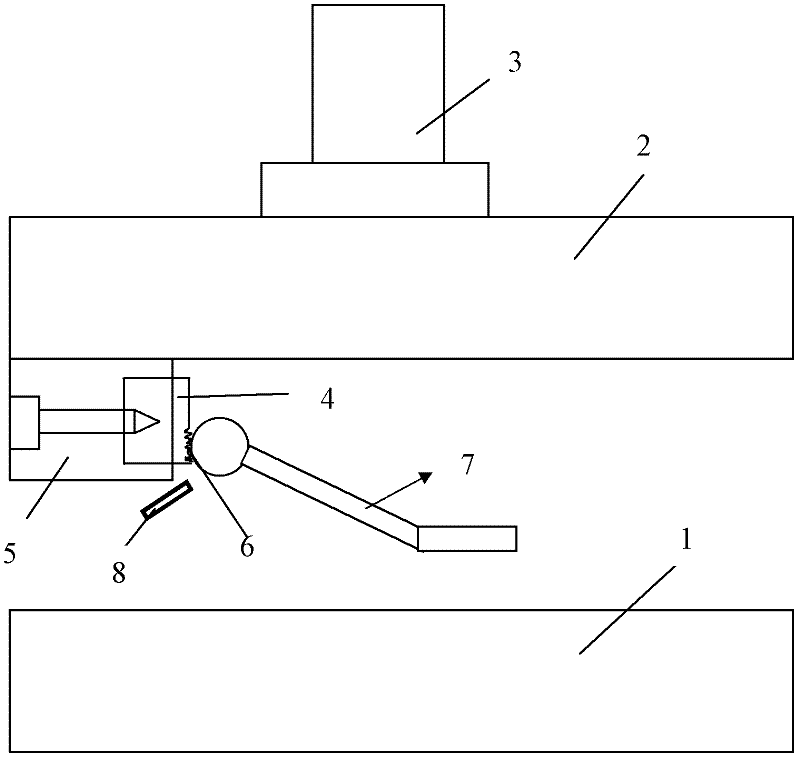

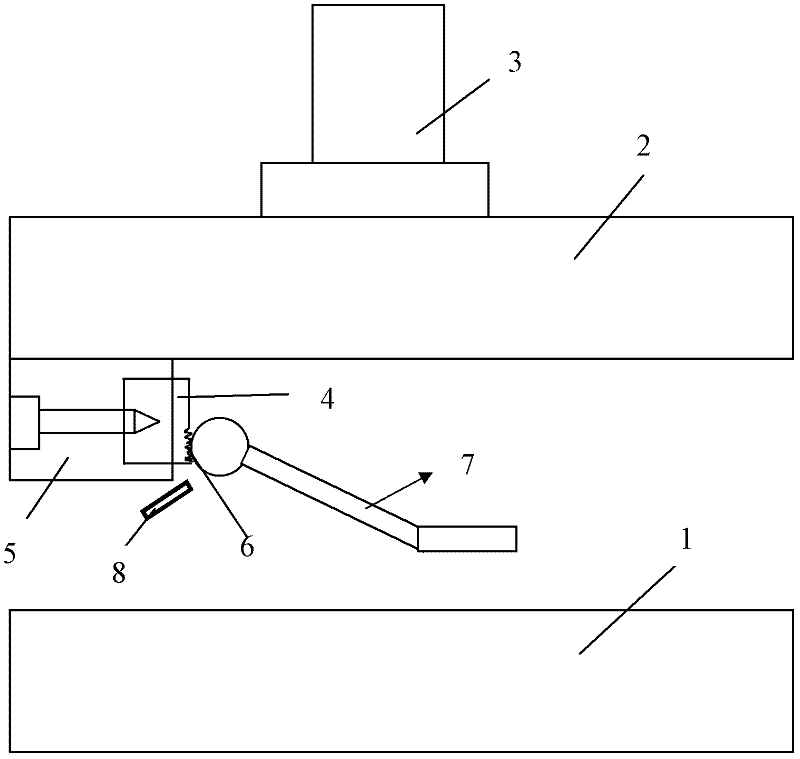

[0012] Such as figure 1 As shown, the stamping and edging device provided by the present invention without manual grinding includes a lower type 1, an upper type 2, a pressing device 3 and a cutter 4; wherein the upper type 2 is installed above the lower type 1 at a distance in a manner that can move up and down , and the bottom surface is provided with a cutter mount 5; the pressurizing device 3 is arranged on the top of the upper type 2, and has a controller thereon; the cutter 4 is installed on one side of the upper mount 5 of the upper type 2 along a vertical method, and The lower part of the outer side is formed with a saw-tooth grinding mouth 6 .

[0013] The pressurizing device 3 is a hydraulic device.

[0014] When it is necessary to use the stamping and edging device provided by the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com