Patents

Literature

39results about How to "Reduce the risk of occupational diseases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

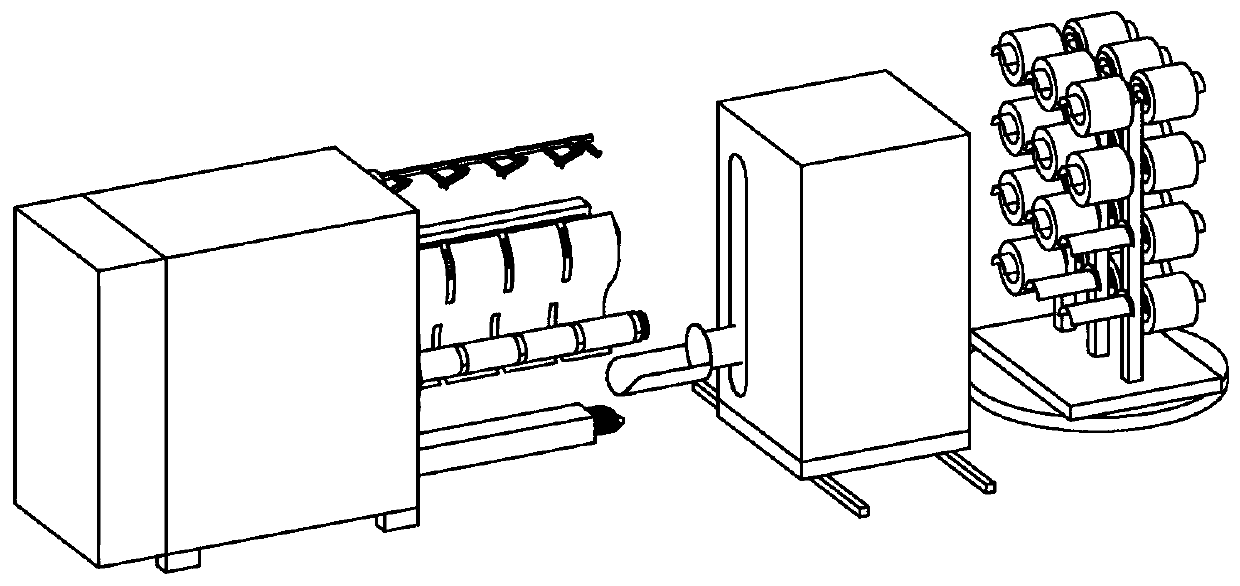

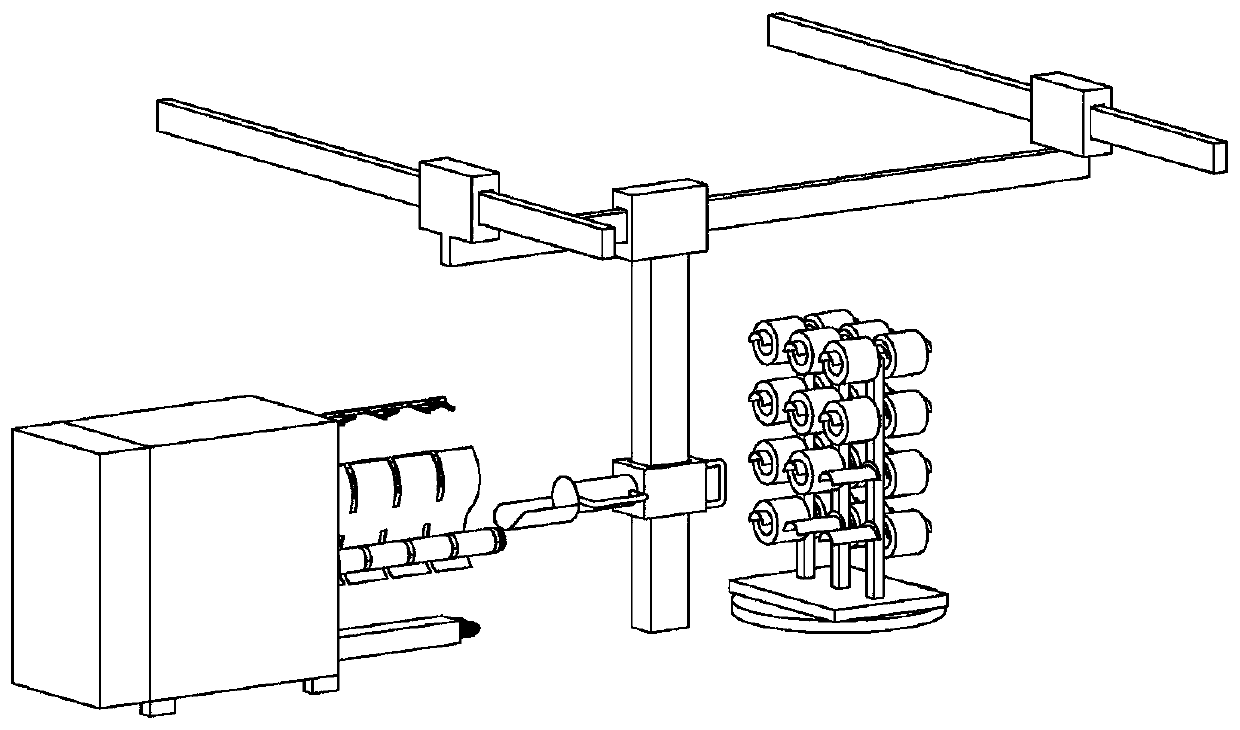

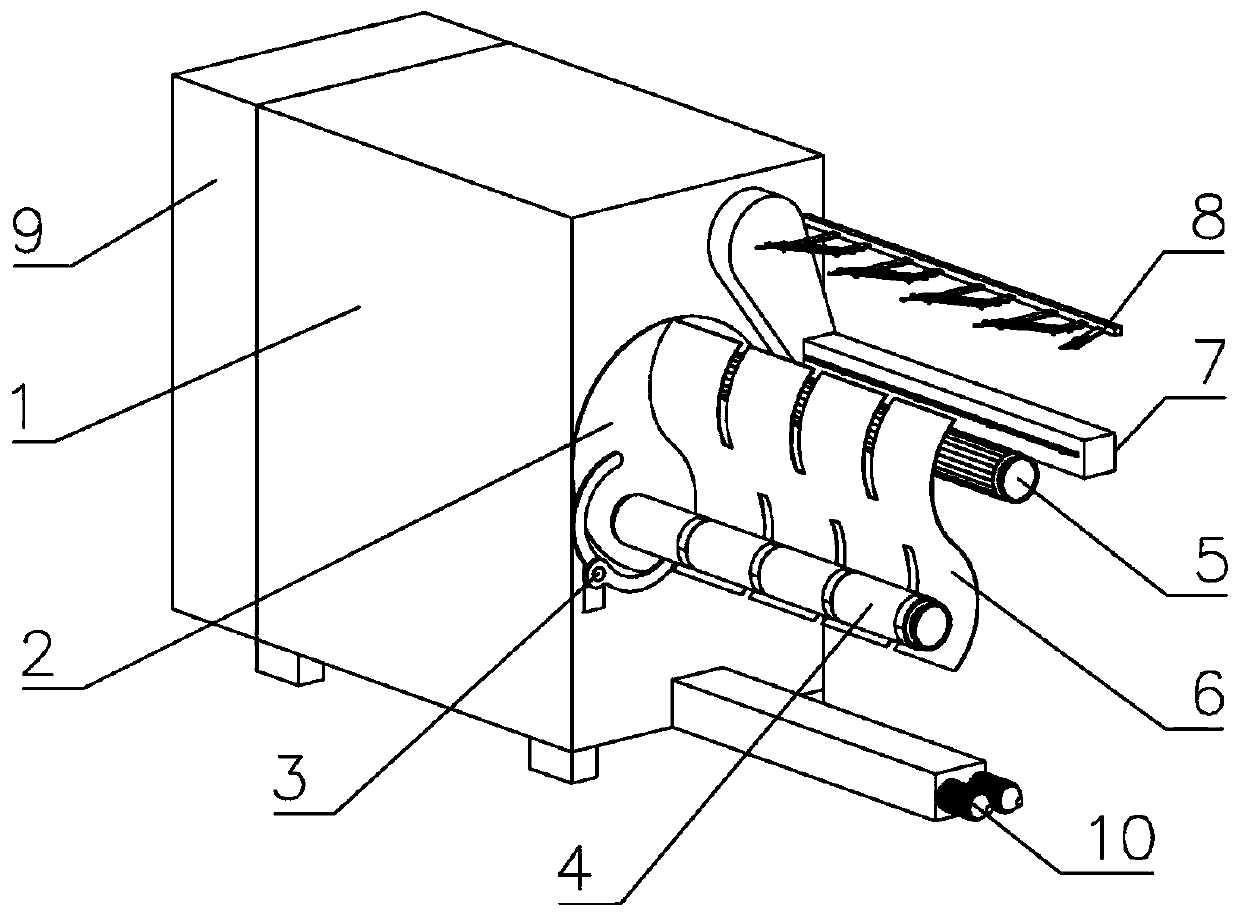

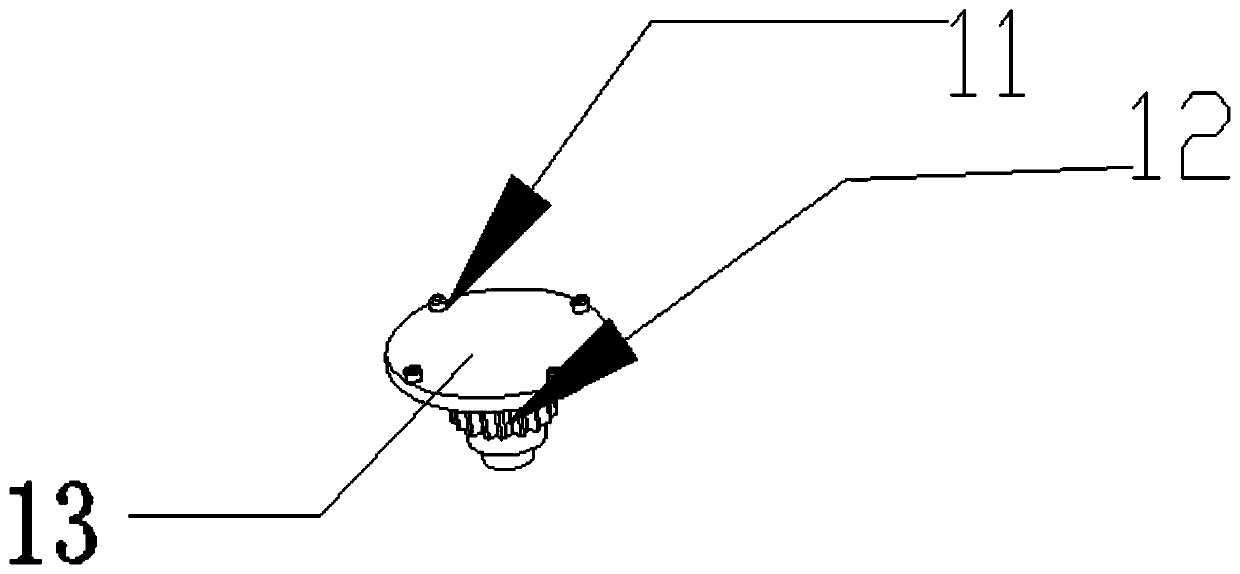

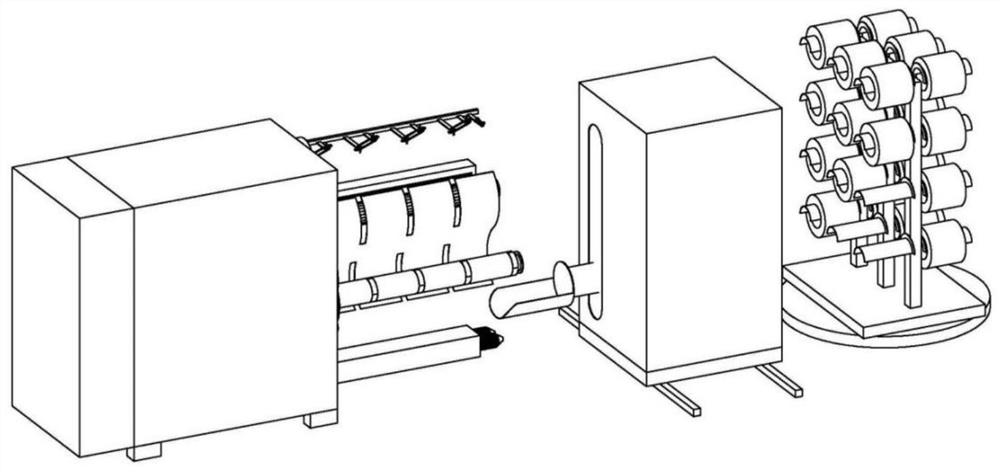

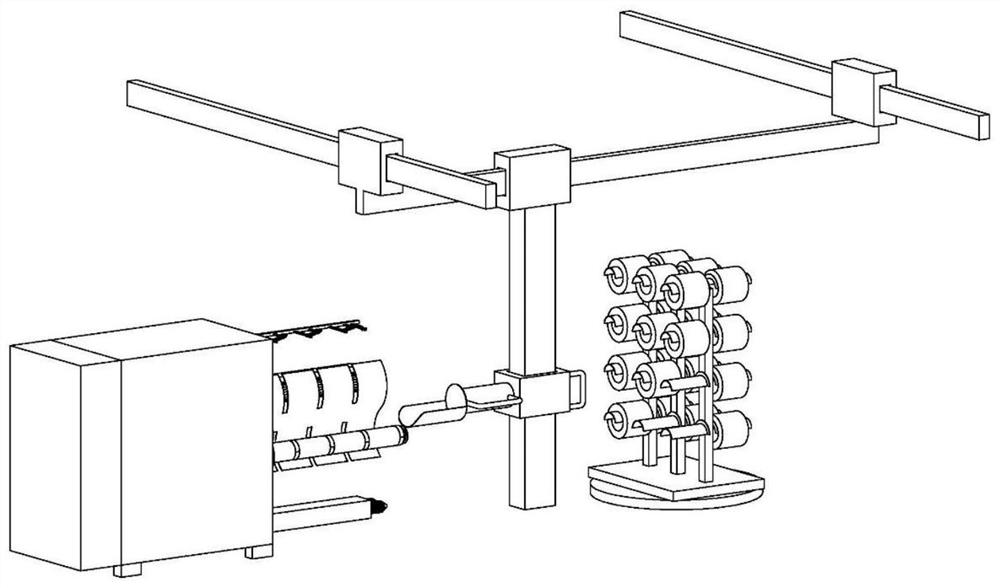

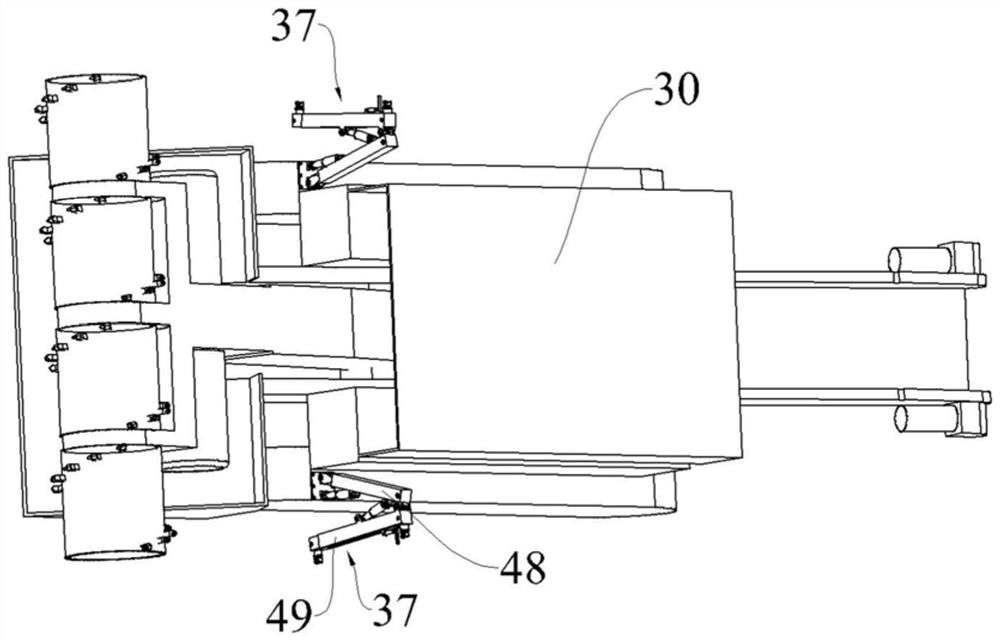

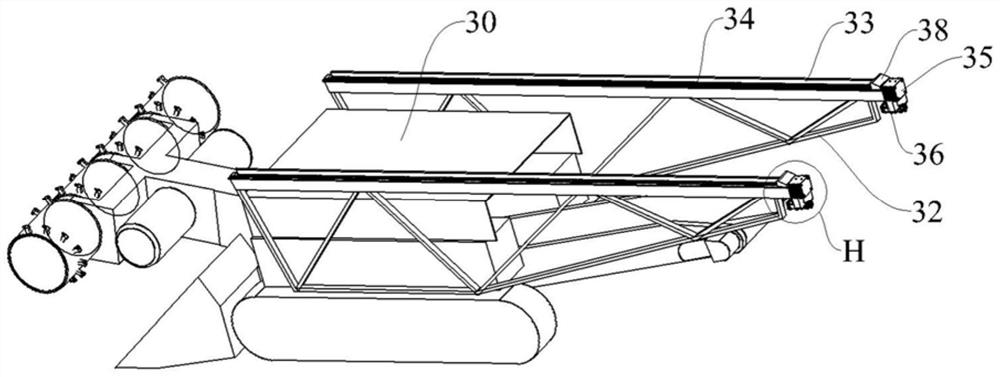

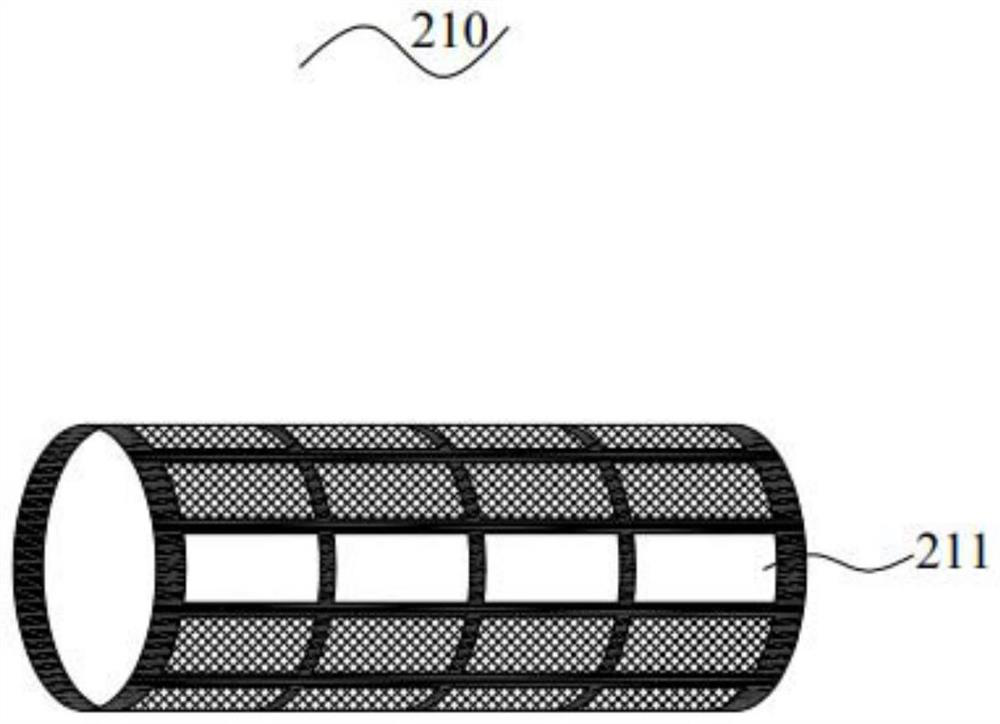

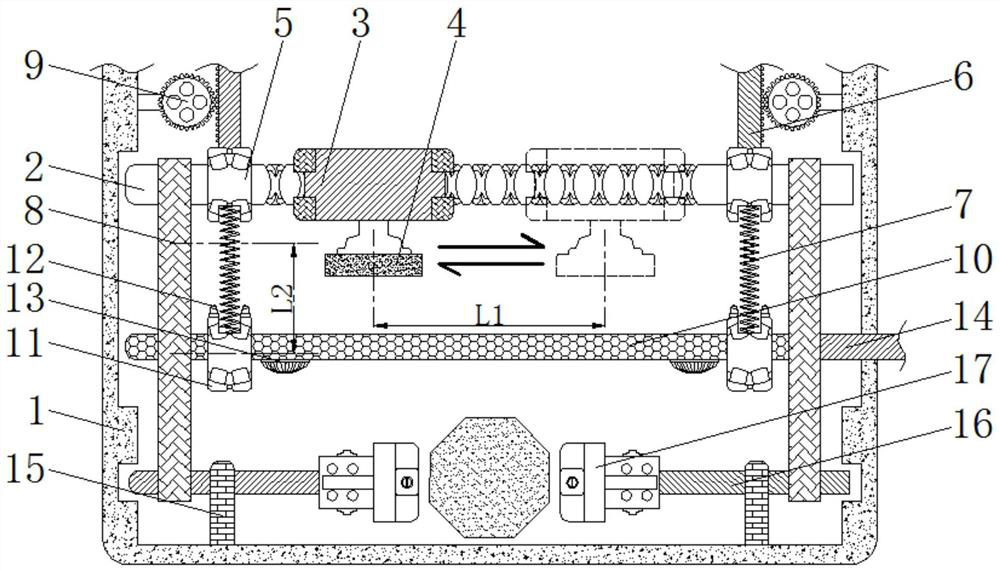

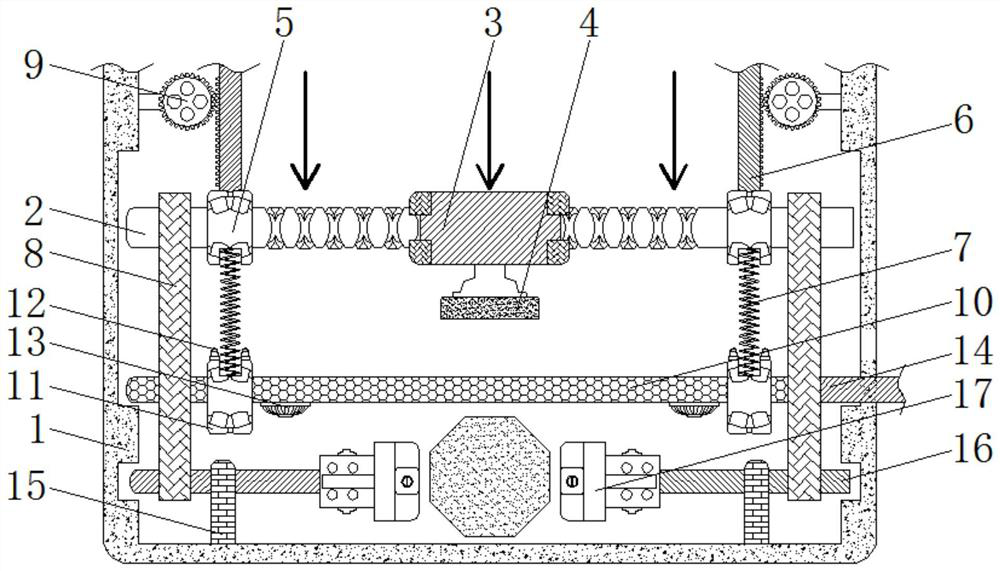

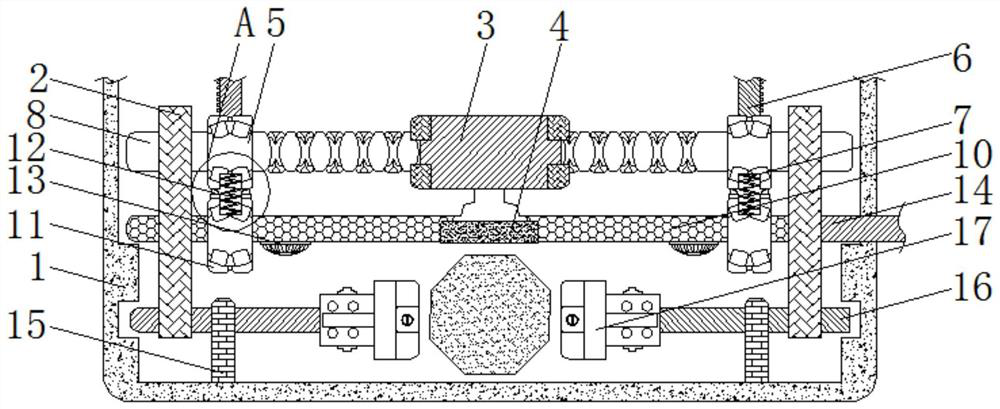

Intelligent glass fiber forming and winding device

An intelligent glass fiber forming and winding device comprises a winding head and a tube changing mechanism installed on a main frame, wherein the tube changing mechanism comprises a rotating disk and a yarn guide, at least one yarn winding tube is sleeved on the winding head and comprises a winding section and a tube changing section, and the tube changing section can be used to cut off and windthe yarn; the yarn guide can rotate clockwise or counterclockwise relative to the main frame and comprises a yarn guide rotating shaft and a tube changing yarn guiding rod and a loading yarn guidingrod that are fixed on the yarn guide rotating shaft, and both ends of the tube changing yarn guiding rod are inconsistent with respect to the axis of the yarn guide rotating shaft such that the yarn guide rotating shaft rotates during the tube changing process, and the yarn can slide from the highest end to the lowest end along the tube changing yarn guiding rod, thereby poking the yarn to the tube changing section on the corresponding winding tube. The intelligent glass fiber forming and winding device provided by the invention has reasonable structure and easy operation, and can effectivelyimprove the production efficiency and product quality of glass fiber.

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

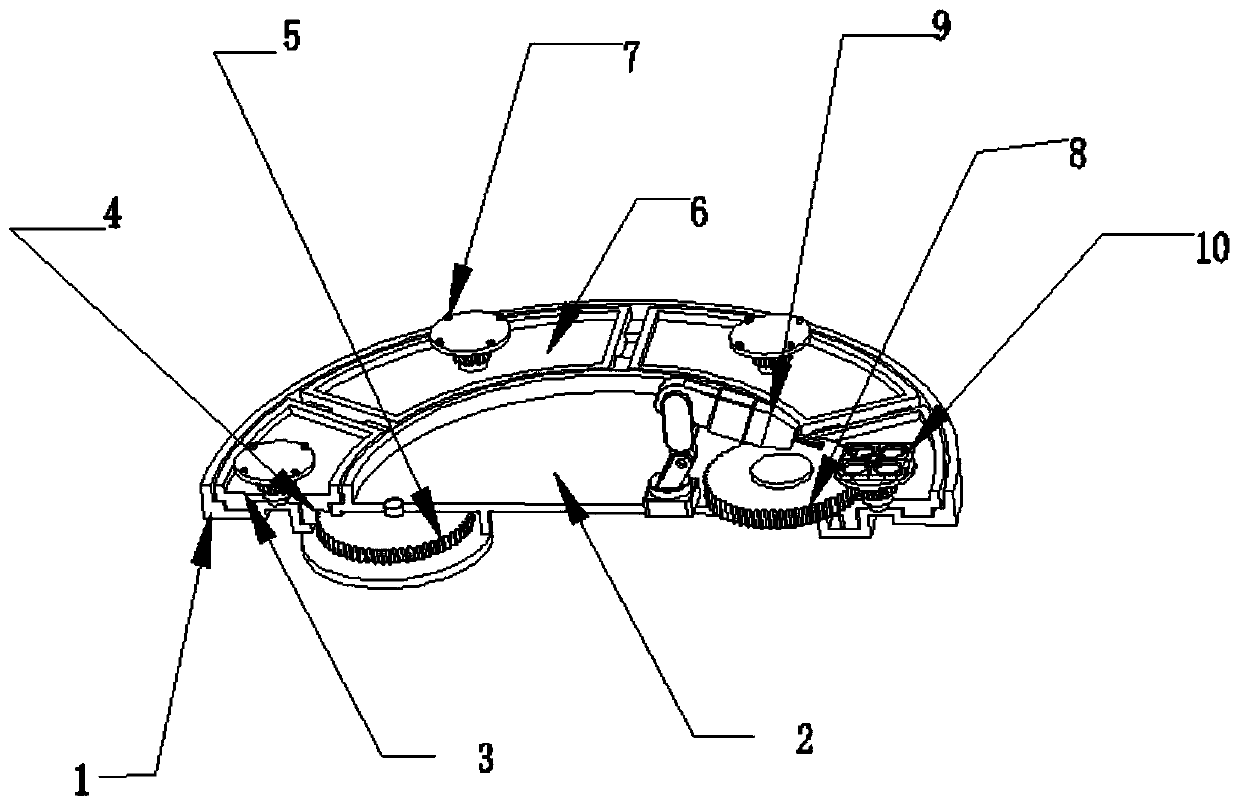

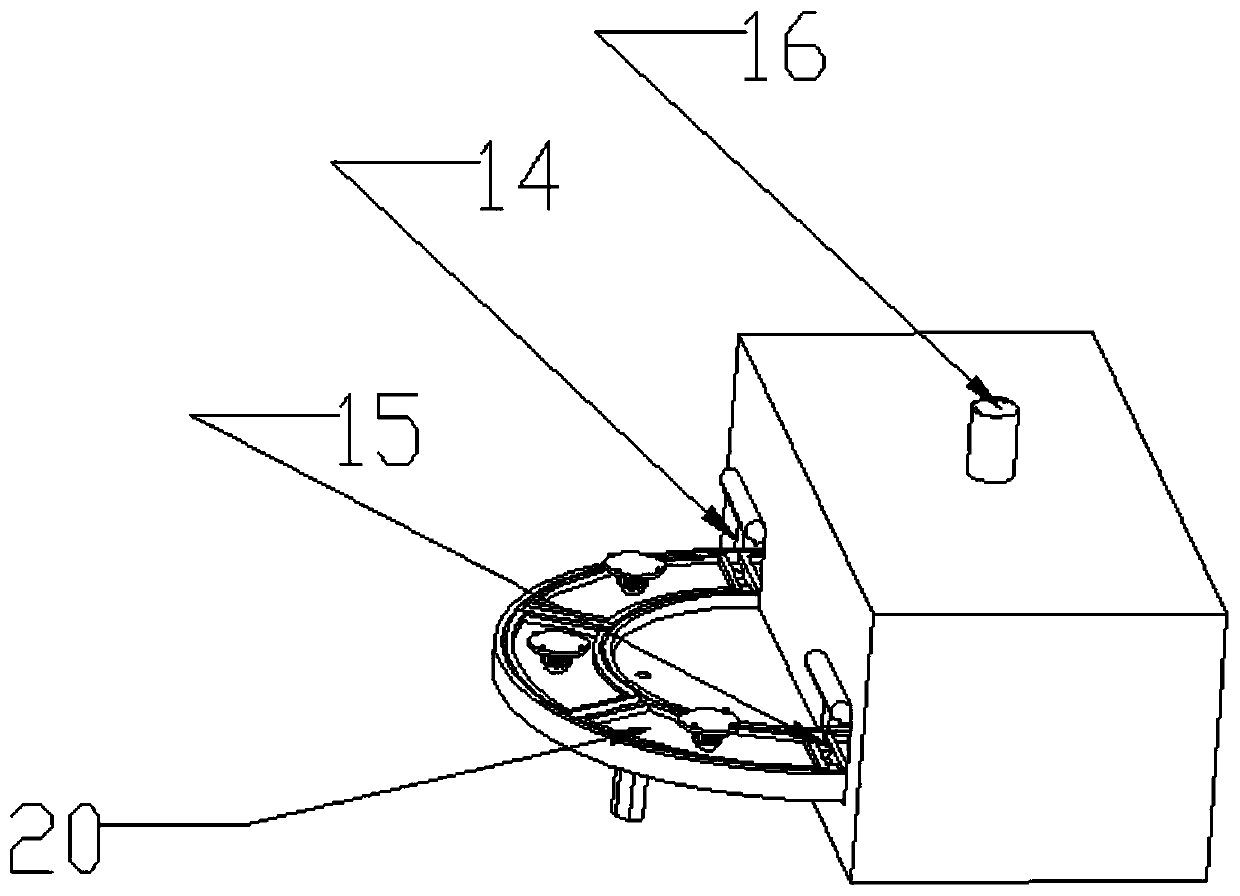

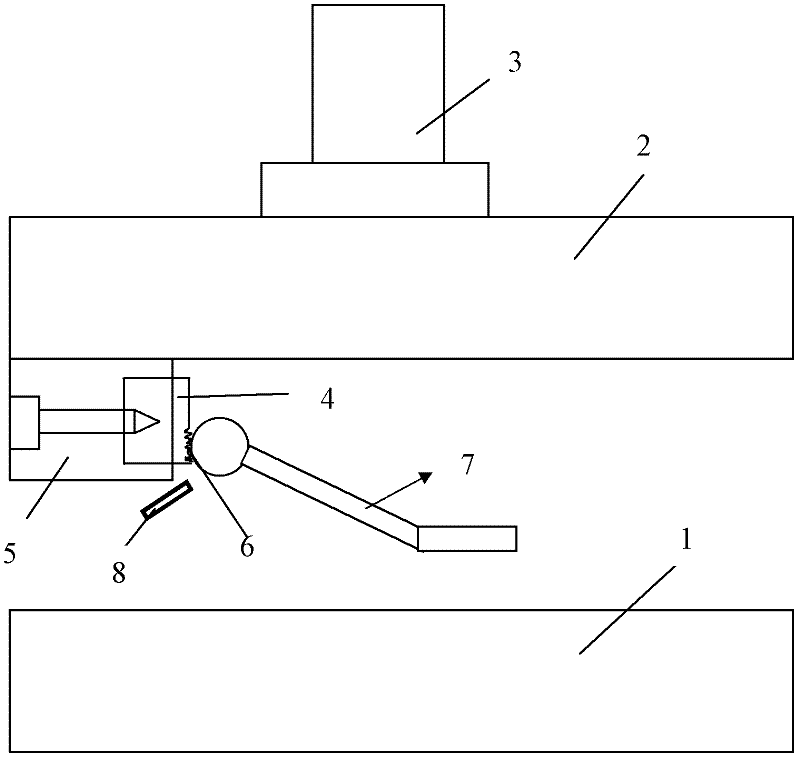

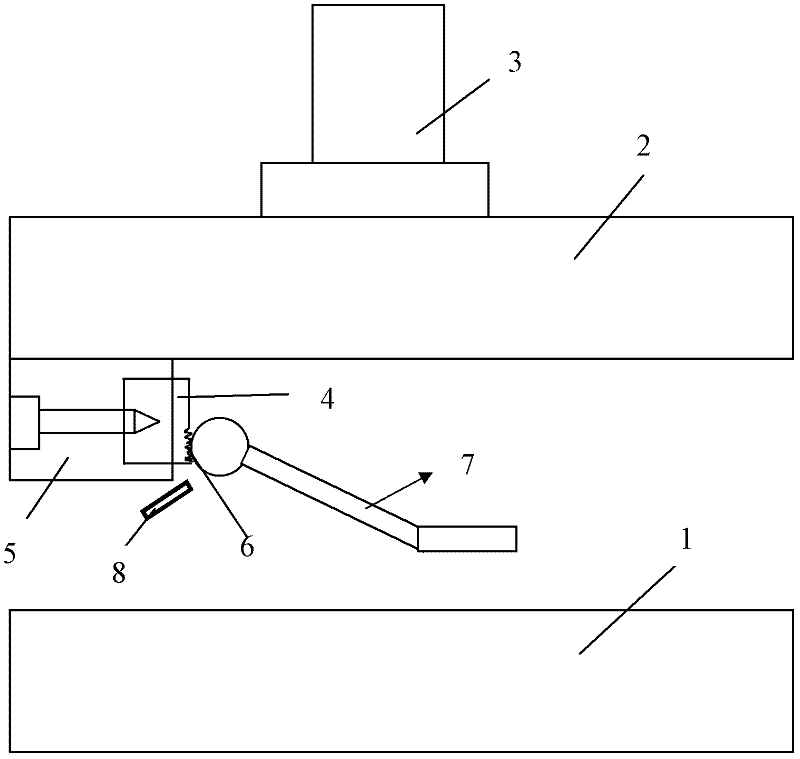

Automatic paint spraying assembly line for plastic parts

The invention provides an automatic paint spraying assembly line for plastic parts. The automatic paint spraying assembly line comprises an automatic paint spraying station rotary disc, a closed paintspraying chamber, a feeding frame and a drying tunnel. The automatic paint spraying station rotary disc comprises a rotary disc mounting frame and a rotary disc mounted in the rotary disc mounting frame. The rotary disc mounting frame is provided with a round tray with a vertical side wall, and a supporting frame. The rotary disc comprises a fixed disc with a vertical side wall arranged on the edge, and a rotating disc, and the rotating disc is mounted in a sliding rail. The rotating disc is provided with multiple stations, and workpiece clamping tools are arranged in the stations. An inner gear engaged with a power gear is arranged on the bottom face of the rotating disc. The fixed disc is provided with a tool power gear engaged with tool gears. An automatic paint spraying robot is further arranged on the fixed disc. The portion, provided with the automatic paint spraying robot, of the automatic paint spraying station rotary disc is located in a body. The feeding frame is put on theside, close to a feed port, of the automatic paint spraying station rotary disc, and the drying tunnel is put in the side, close to a discharge port, of the automatic paint spraying station rotary disc. Automatic paint spraying of the plastic parts is achieved.

Owner:ZHEJIANG LAISIAO ELECTRIC

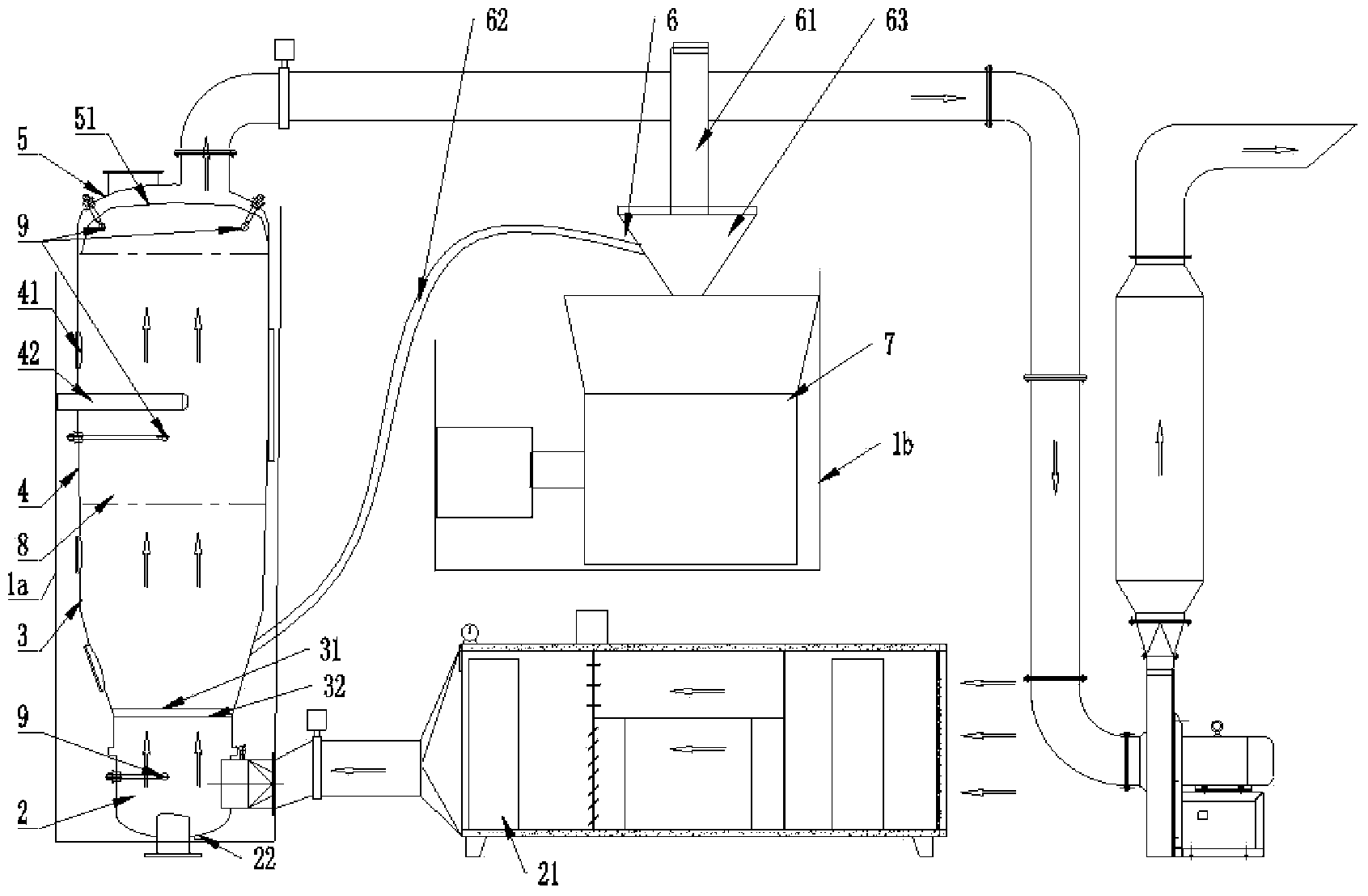

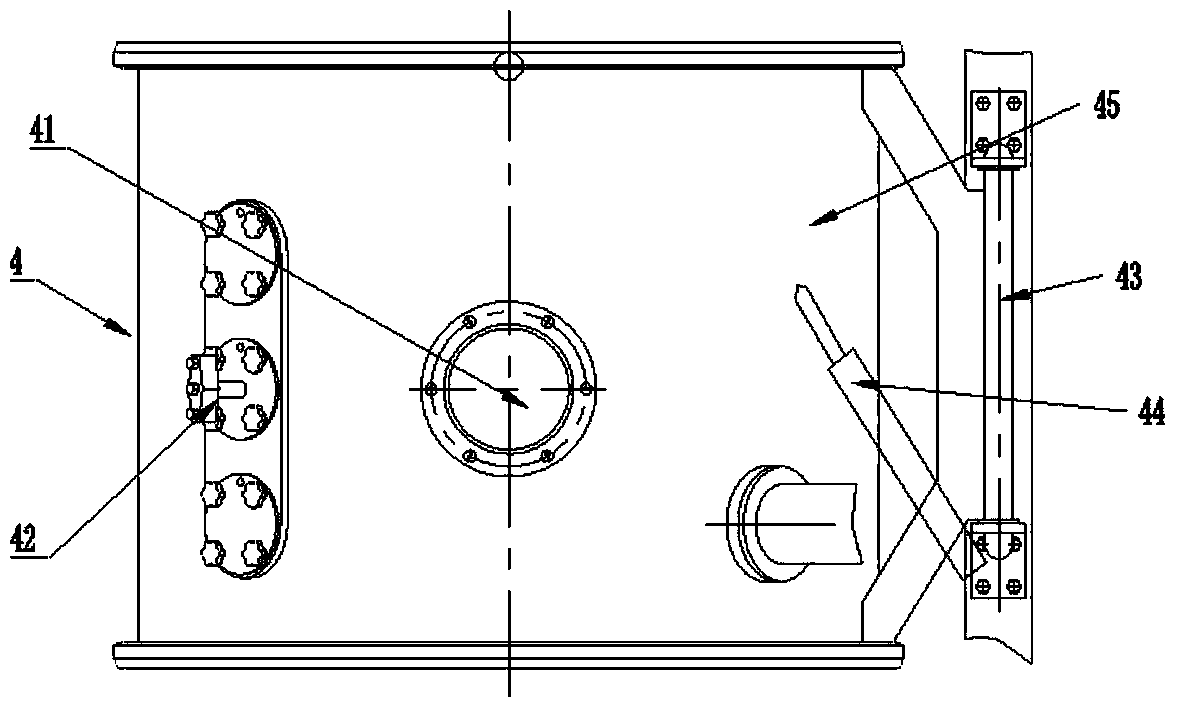

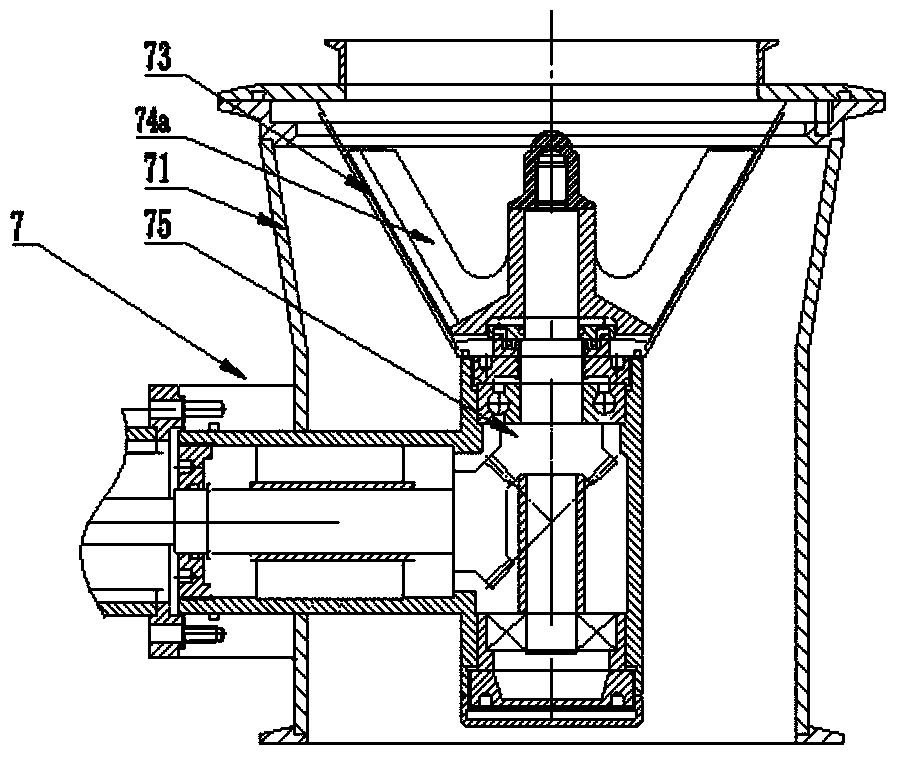

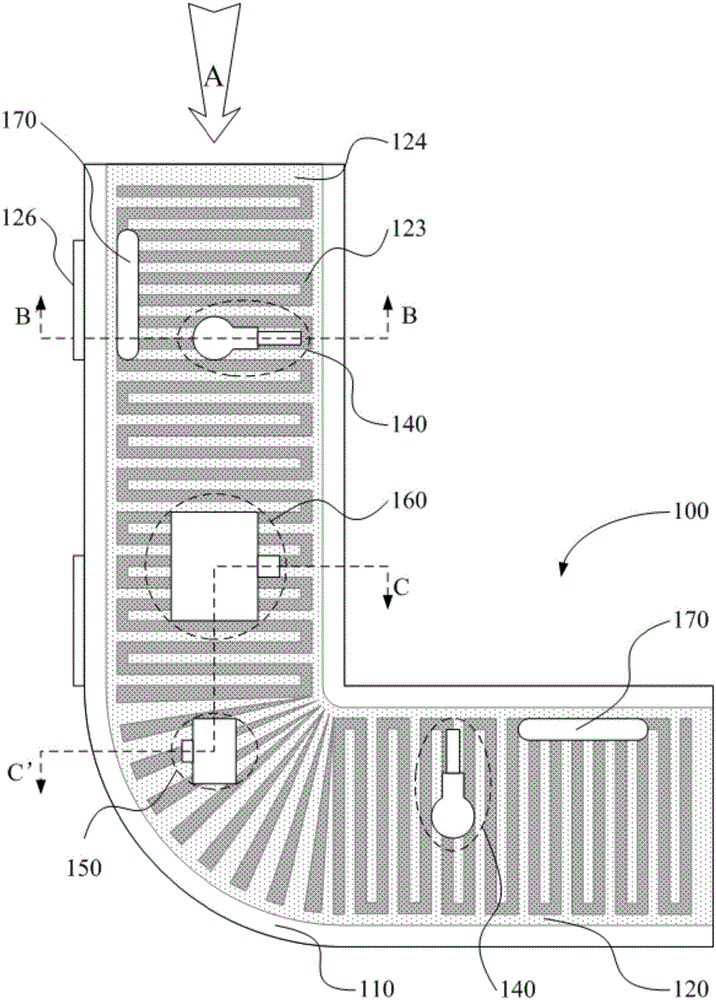

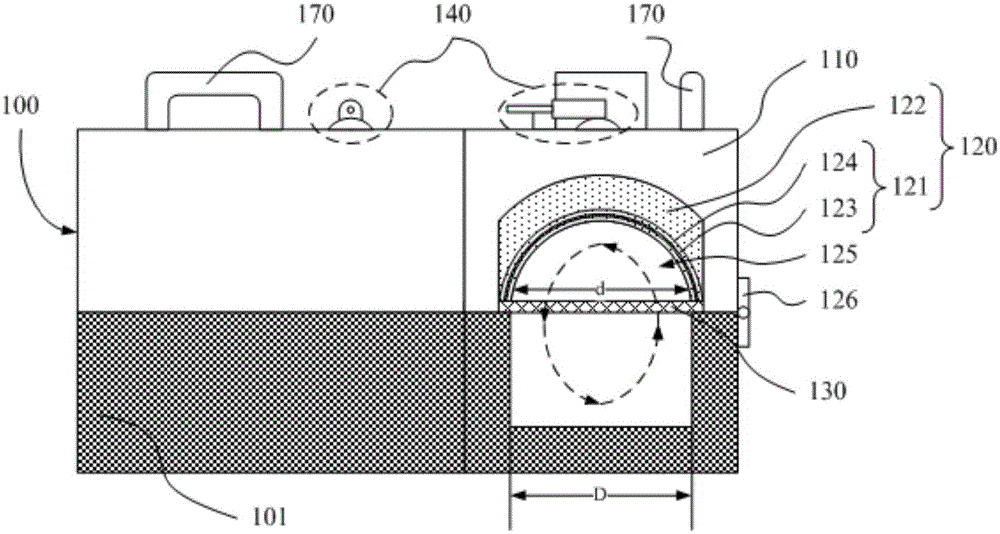

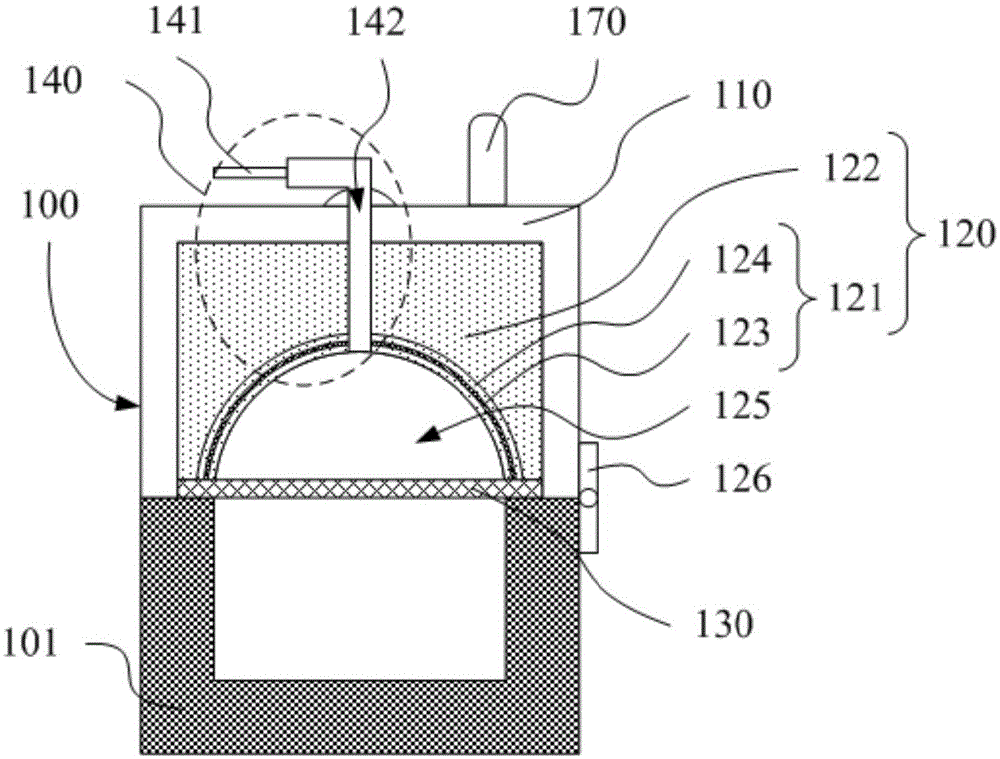

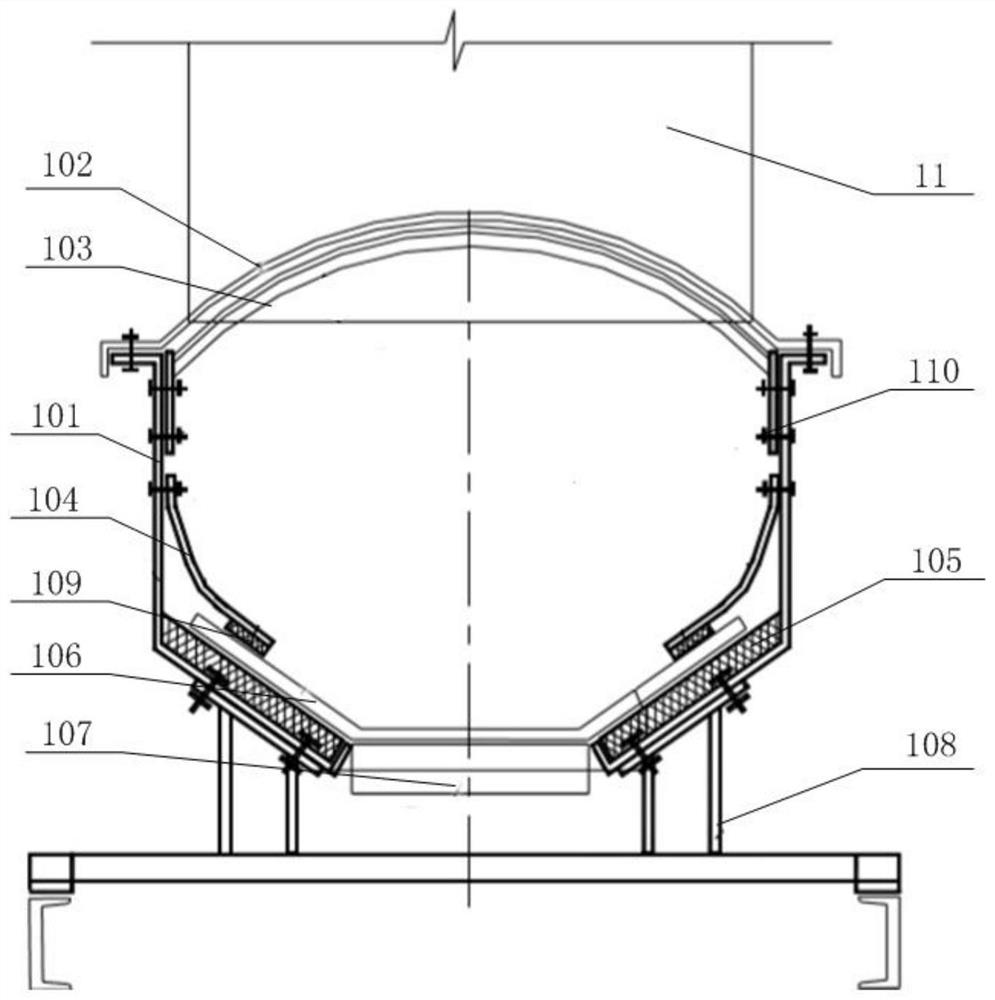

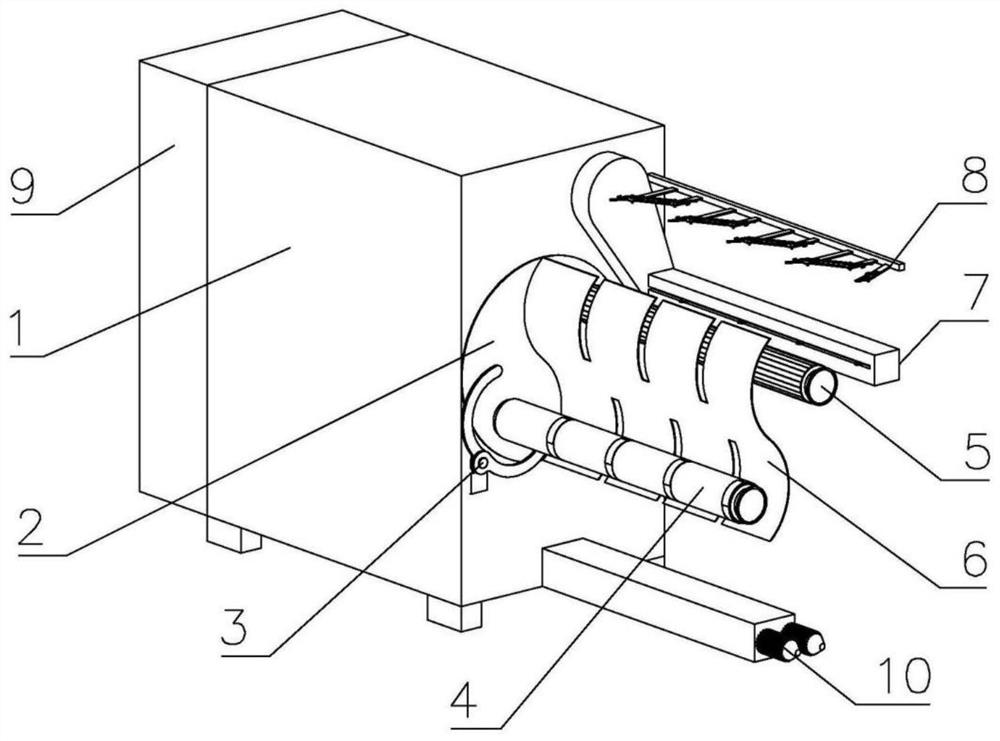

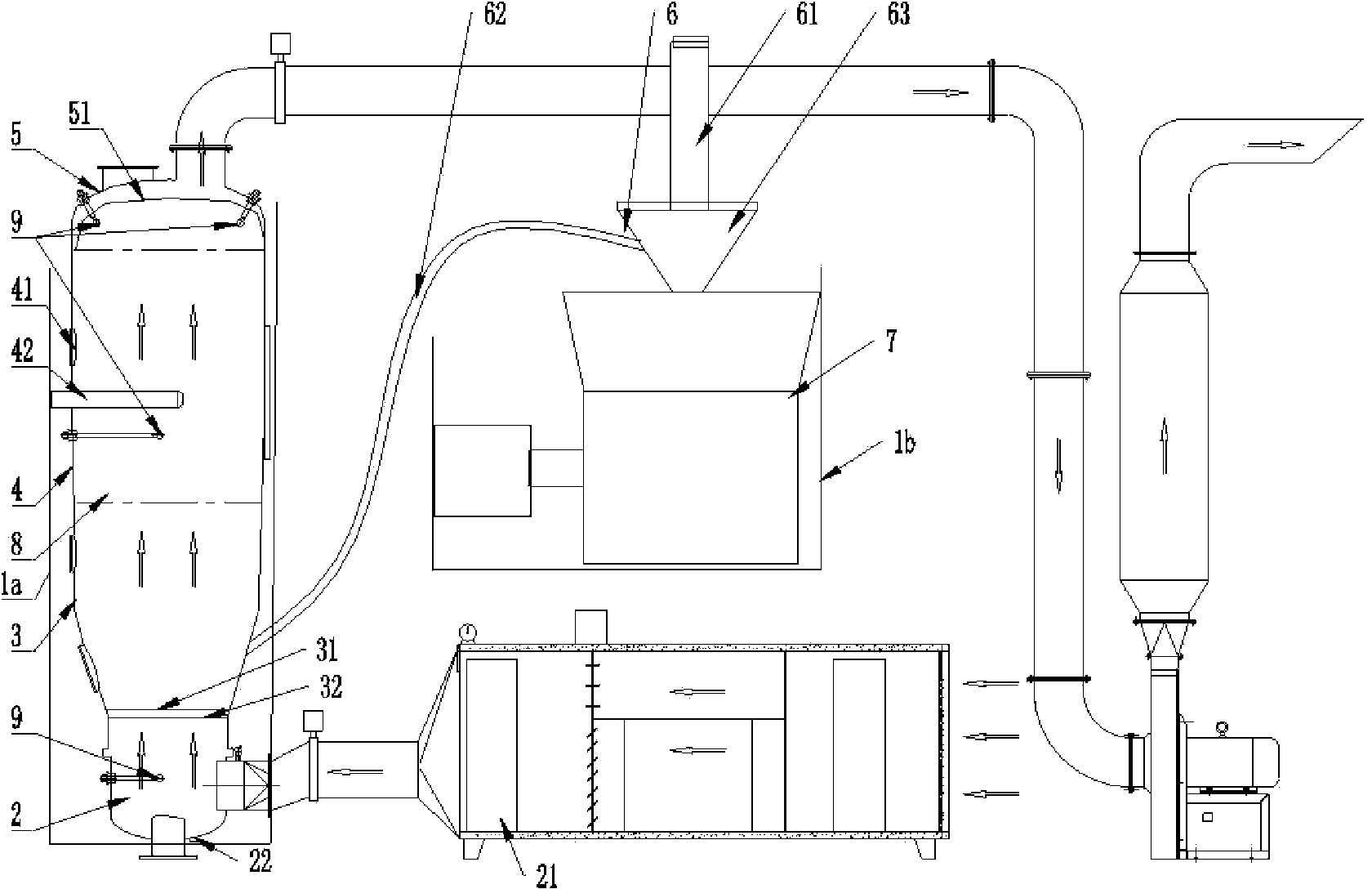

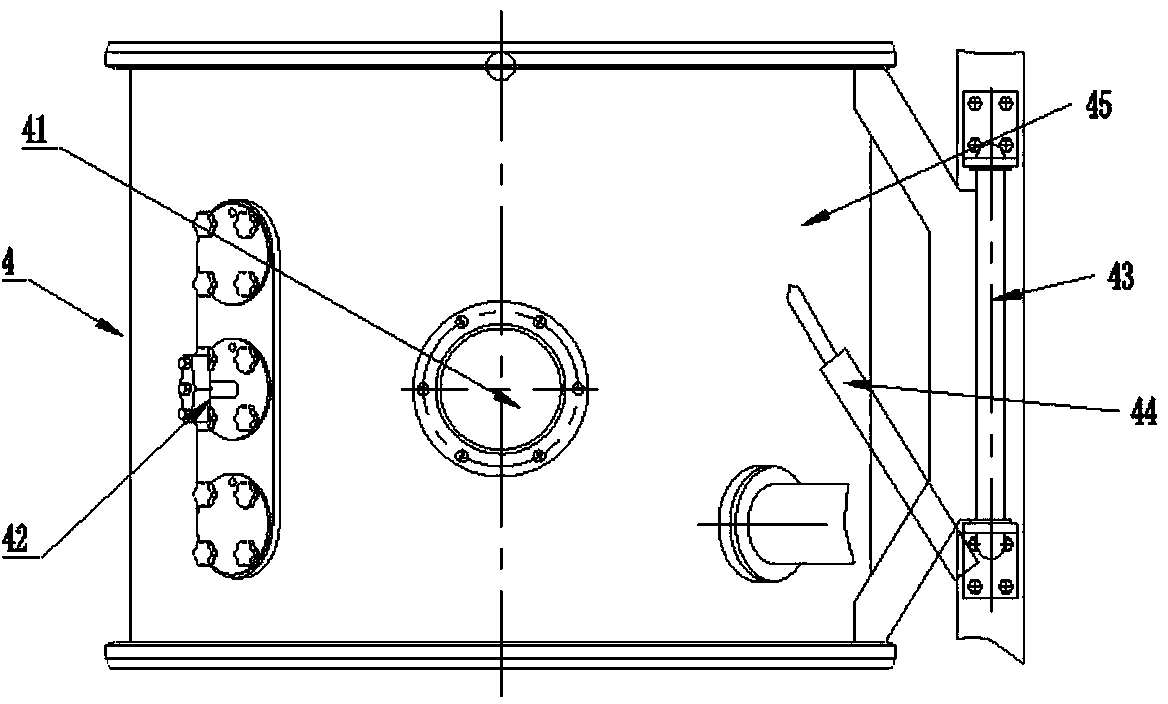

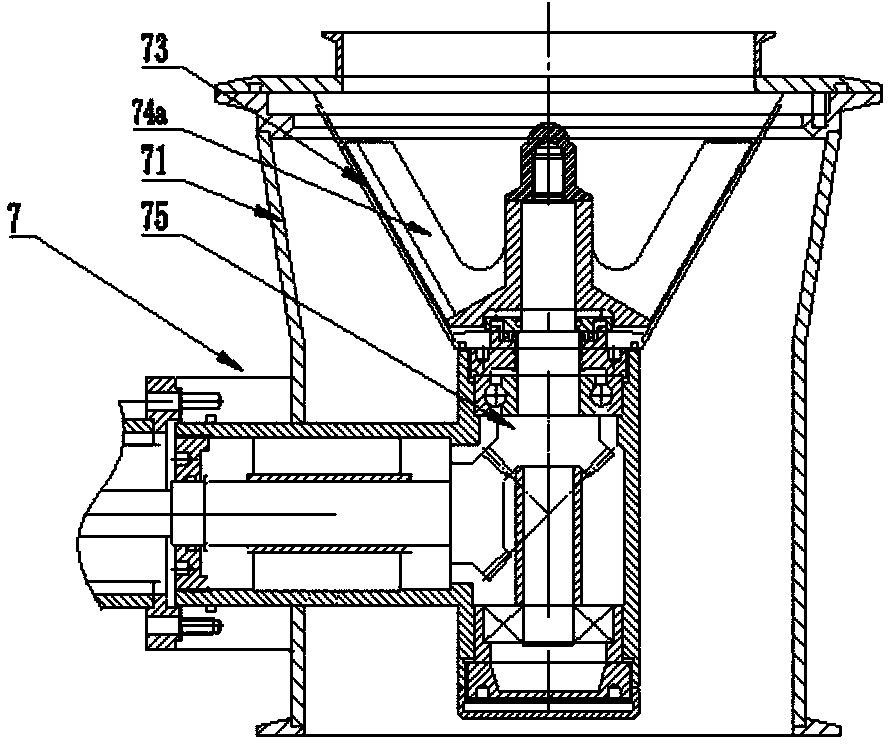

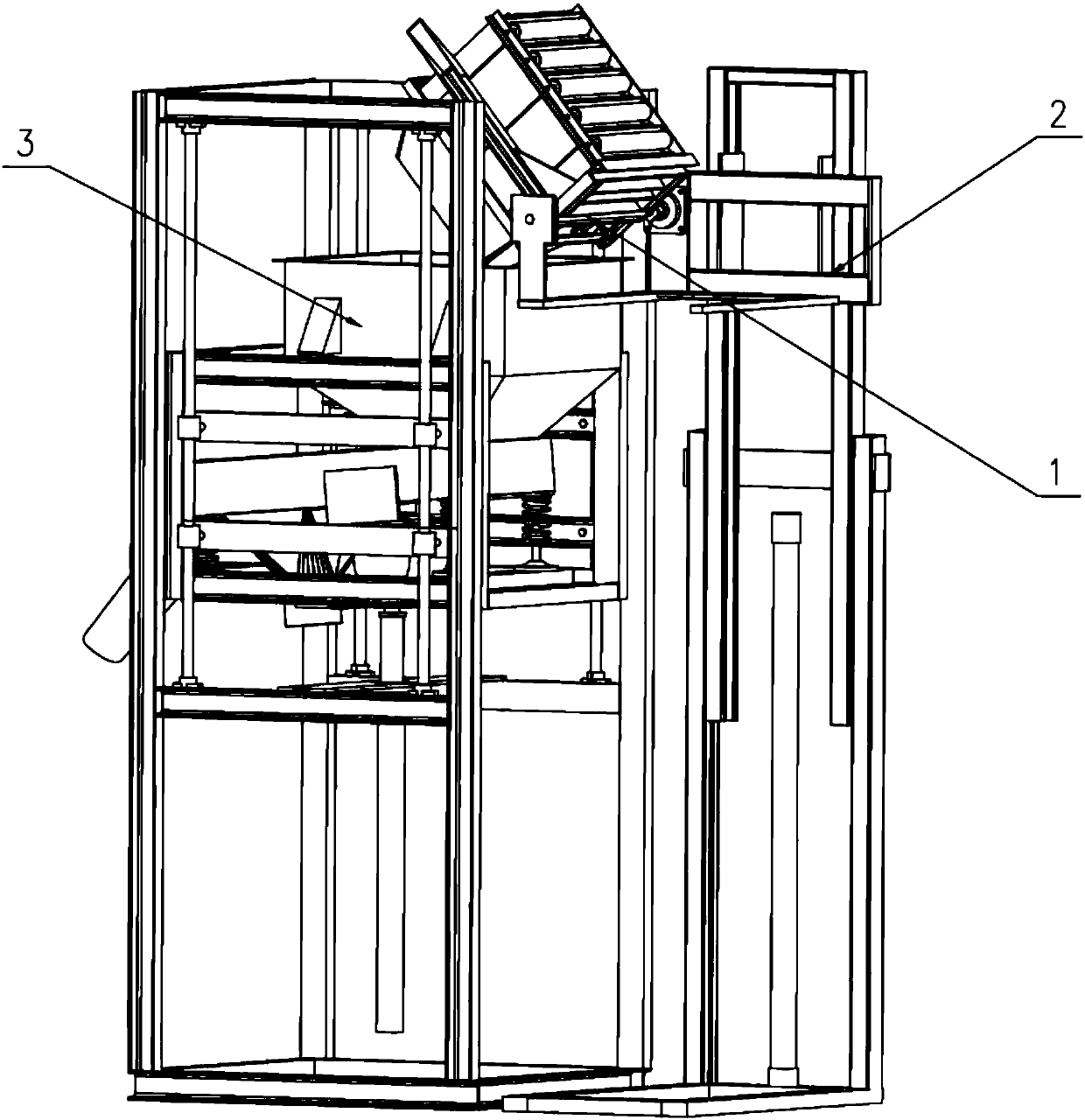

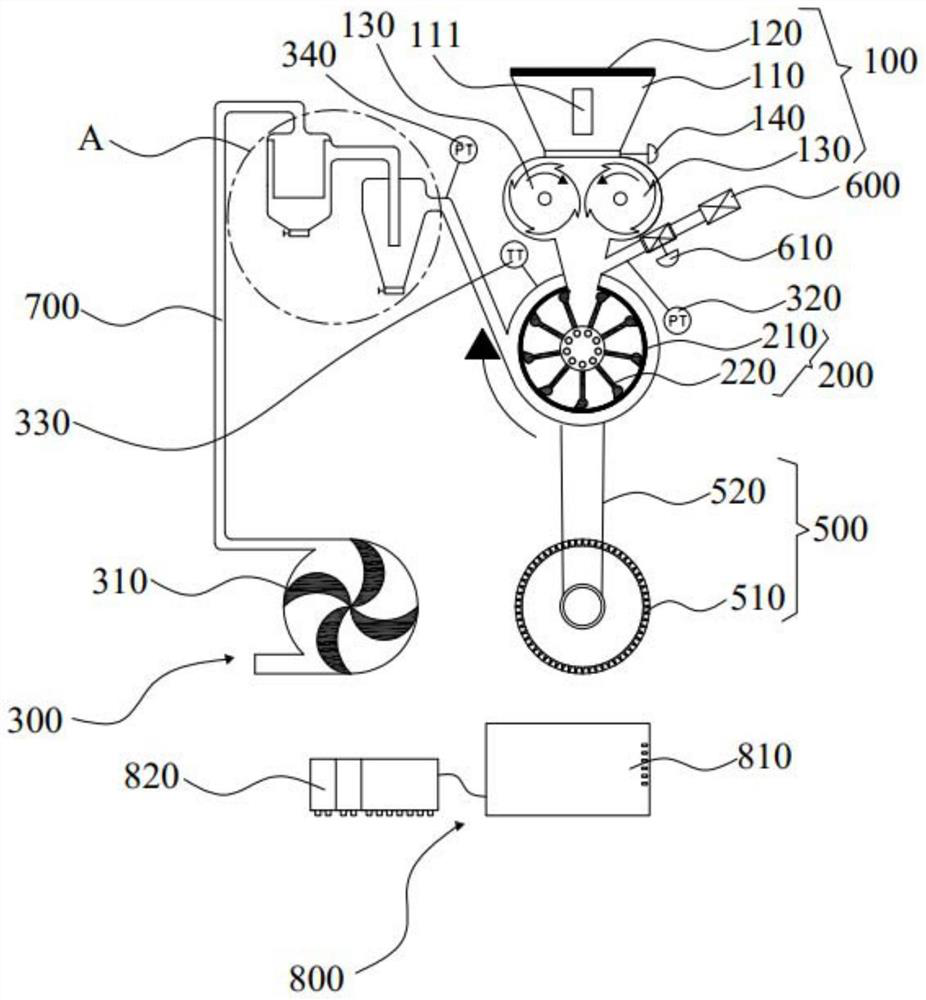

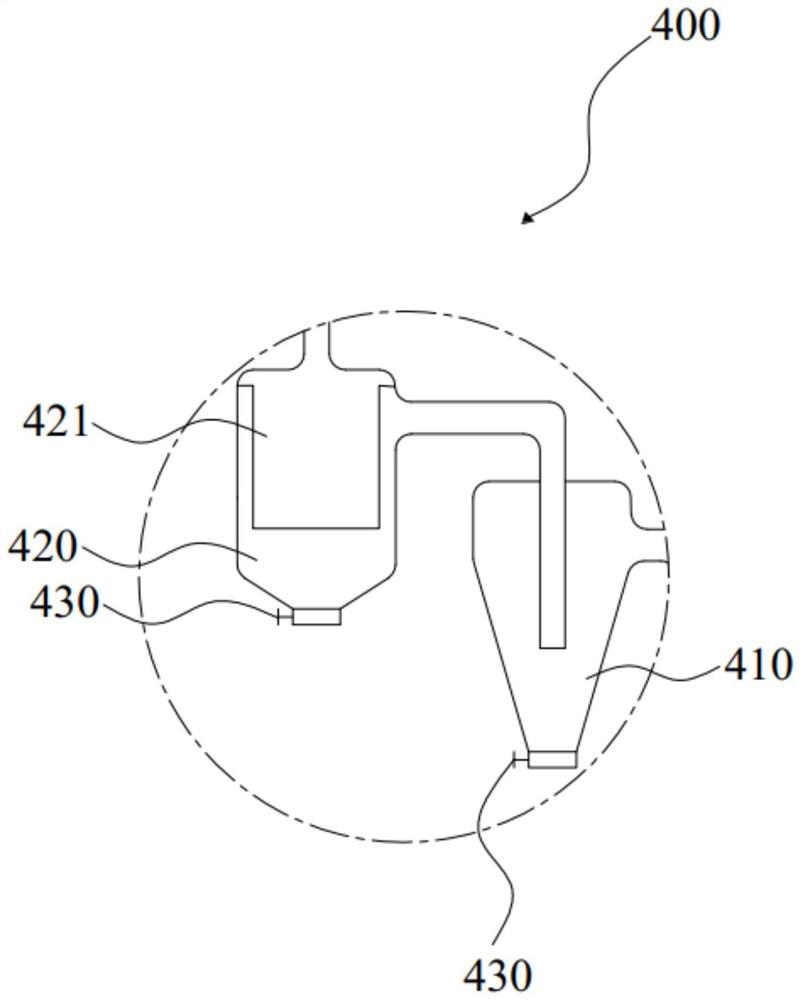

Airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device

ActiveCN103505371AEffective controlReduce frequent cloggingPharmaceutical product form changeTowerAutomation

The invention discloses an airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device which is simple and reasonable in structure, airtight and free of pollution in the whole process and high in automation degree. The airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device comprises a material drying boiling cavity, a granule arranging system and a corresponding control device. The material drying boiling cavity is a tower type integrated drying boiling cavity which comprises an air inlet system, a granulation material bucket component, a middle bucket body component and an air exhausting dust removal system. A material conveying system is arranged between the granule arranging system and the tower type integrated drying boiling cavity, and the material conveying system comprises a conveying channel between the tower type integrated drying boiling cavity and the granule arranging system.

Owner:YICHUN WANSHEN PHARMA MACHINERY

Water-based high-temperature-resistant anti-corrosion composition

PendingCN112831252AImprove anti-corrosion performanceImprove performanceFireproof paintsAntifouling/underwater paintsAdhesive cementMischmetal

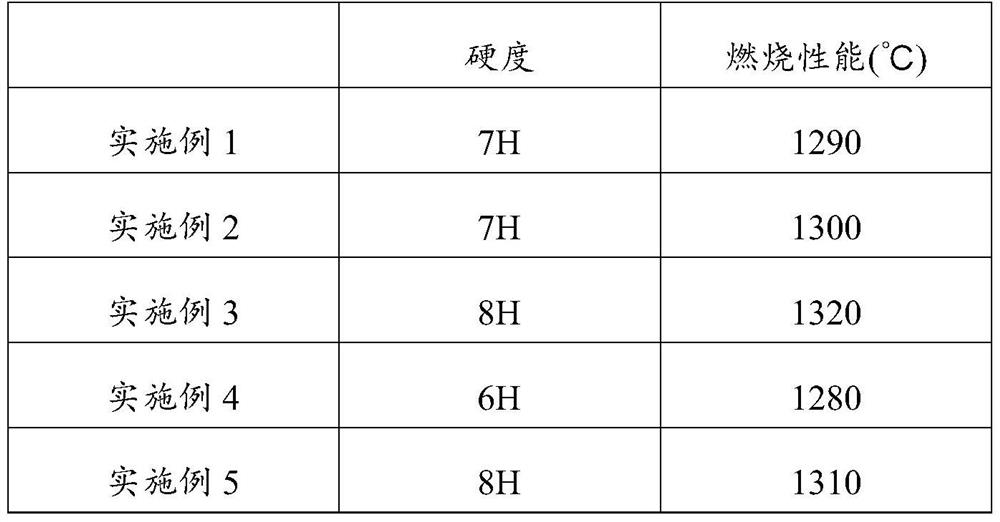

The invention discloses a water-based high-temperature-resistant anti-corrosion composition which comprises the following components in parts by weight: 45-90 parts of a polymer matrix, 15-70 parts of compact filling powder, 0.5-4 parts of rare earth metal, 5-40 parts of a dispersing agent, 2-25 parts of a flatting agent and 10-30 parts of an inorganic adhesive. The water-based high-temperature-resistant anti-corrosion composition is good in anti-corrosion performance, does not re-rust in a high-salt environment and particularly has more outstanding performance in corrosion environments such as salt mist and acid rain, the ultraviolet aging resistance is 3-5 times that of a traditional coating, the salt mist test can reach 2400 h or above, and the service life of the water-based high-temperature-resistant anti-corrosion composition meets the requirement of Centennial Project. The water-based high-temperature-resistant anti-corrosion composition disclosed by the invention is high-temperature-resistant and non-combustible, is an A-grade fireproof non-combustible material, has ultrahigh surface hardness which can reach 4-9H, particularly outstanding scratch resistance and good impact resistance, and can meet the requirements of various special environments.

Owner:烟台万华新材料技术有限公司

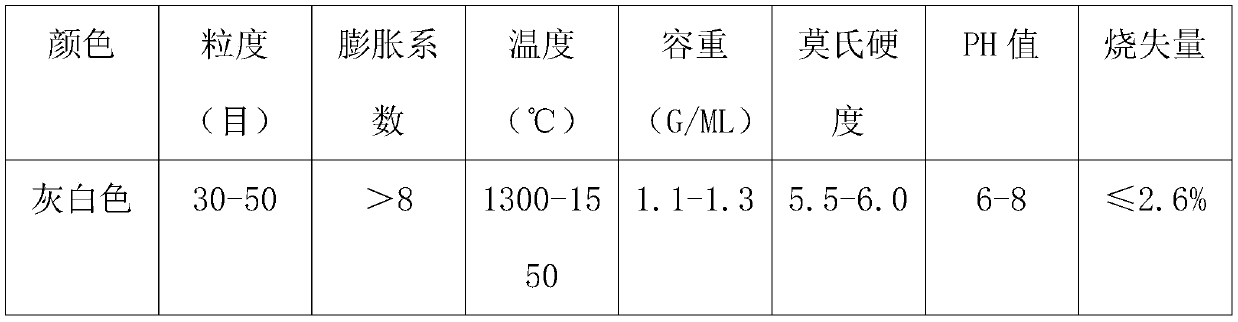

Deslagging agent used for smelting cast iron and preparation method thereof

The invention discloses a deslagging agent used for smelting cast iron and a preparation method thereof. The deslagging agent comprises, by weight, 70%-75.2% of silicon dioxide, 12.1%-15.9% of aluminum oxide, 0.5%-1.9% of ferric oxide, 1.2%-3.22% of sodium oxide, 1.9%-3.84% of potassium oxide, 0.9%-1.48% of calcium oxide, 0.47%-1.46% of magnesium oxide, and the balance iron and inevitable impurities. The deslagging agent used for smelting the cast iron mainly comprises SiO2 and Al2O3 and can instantly expand when sharply heated to the temperature of 1100DEG C or over so as to form a viscous active material of a porous structure, so that molten iron, slag in the molten iron, and impurities can adhere together to be gathered; the deslagging agent has a low heat conductivity coefficient so that heat conduction and thermal radiation on the surface of the molten iron can be effectively reduced, and a heat preservation effect is achieved; and the problems, such as corrosive pits, white spotsand wrinkles, which occur frequently during cast iron machining are solved while the defects are overcome.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Normal-temperature asphalt modifier, modified asphalt and asphalt concrete

ActiveCN105001656AEmission reductionReduced emission reductionsBuilding insulationsBulk chemical productionPolymer alloyPolymer science

The invention provides a normal-temperature asphalt modifier, modified asphalt and asphalt concrete. The normal-temperature asphalt modifier is a mixture containing waste engine oil, rubber tires and plastic extract. The normal-temperature asphalt modifier is added to matrix asphalt at the temperature of 130 DEG C-150 DEG C, and the mixture is stirred, so that the modified asphalt is obtained. The asphalt concrete comprises the modified asphalt and mineral aggregates. The normal-temperature asphalt modifier utilizes three or more high-molecular polymers including the waste engine oil, the rubber tires, the plastic extract and the like, and the three or more high-molecular polymers are blended to form a polymer alloy with an interpenetrating polymer network. A storable road normal-temperature asphalt modifier can be obtained by the asphalt modified by the normal-temperature asphalt modifier. The asphalt concentrate has the advantages of low carbon, energy saving, environment protection, availability in case of pavement, little repair, low construction cost, good adaptability, long service life, convenience in construction, health and low station construction cost.

Owner:XIAN YONGHE TECH CO LTD

Tin inlay mold and method for producing tin inlay technique pattern

InactiveCN101486072AMeet the scaleSatisfy industrializationDecorative surface effectsFoundry mouldsCompression moldingMolding machine

The invention relates to a method for producing handicraft articles, in particular to a method for manufacturing a tin-embedded die and a tin-embedded technological pattern. The tin-embedded die is made of silica gel. The step for manufacturing the tin-embedded technological pattern comprises the following steps: manufacturing a stone die, engraving the stone die according to layout work, and arranging a liquid casting flow passage; melting passivated tin into a tin liquid; injecting the tin liquid into the stone die, and taking out a pattern after solidification; removing redundant parts of the pattern, and using sand paper to grind the surface of the pattern; manufacturing a master die; manufacturing a silica gel die blank; placing the master die on the surface of the silica gel die blank, and placing the silica gel die blank on a press molding machine for heating and compression molding; taking out the master die from a silica gel die after cooling, and obtaining the silica gel die; melting passivated tin into a tin liquid; and injecting the tin liquid into the silica gel die, taking out the pattern after the tin liquid is solidified, and obtaining the tin-embedded technological pattern after edging. The method has the advantages that due to adoption of the silica gel die, the finely chiseled master die can be preserved and used permanently after compression molding; die turnover for a plurality of times is not required; and the method can meet the requirements of scale and industrialization of the handicraft articles.

Owner:谷伟

Normal temperature asphalt modifier, normal temperature modified asphalt and warm mix cold asphalt concrete

ActiveCN105001656BEmission reductionReduced emission reductionsBuilding insulationsBulk chemical productionThermodynamicsPolymer alloy

The invention provides a normal-temperature asphalt modifier, modified asphalt and asphalt concrete. The normal-temperature asphalt modifier is a mixture containing waste engine oil, rubber tires and plastic extract. The normal-temperature asphalt modifier is added to matrix asphalt at the temperature of 130 DEG C-150 DEG C, and the mixture is stirred, so that the modified asphalt is obtained. The asphalt concrete comprises the modified asphalt and mineral aggregates. The normal-temperature asphalt modifier utilizes three or more high-molecular polymers including the waste engine oil, the rubber tires, the plastic extract and the like, and the three or more high-molecular polymers are blended to form a polymer alloy with an interpenetrating polymer network. A storable road normal-temperature asphalt modifier can be obtained by the asphalt modified by the normal-temperature asphalt modifier. The asphalt concentrate has the advantages of low carbon, energy saving, environment protection, availability in case of pavement, little repair, low construction cost, good adaptability, long service life, convenience in construction, health and low station construction cost.

Owner:XIAN YONGHE TECH CO LTD

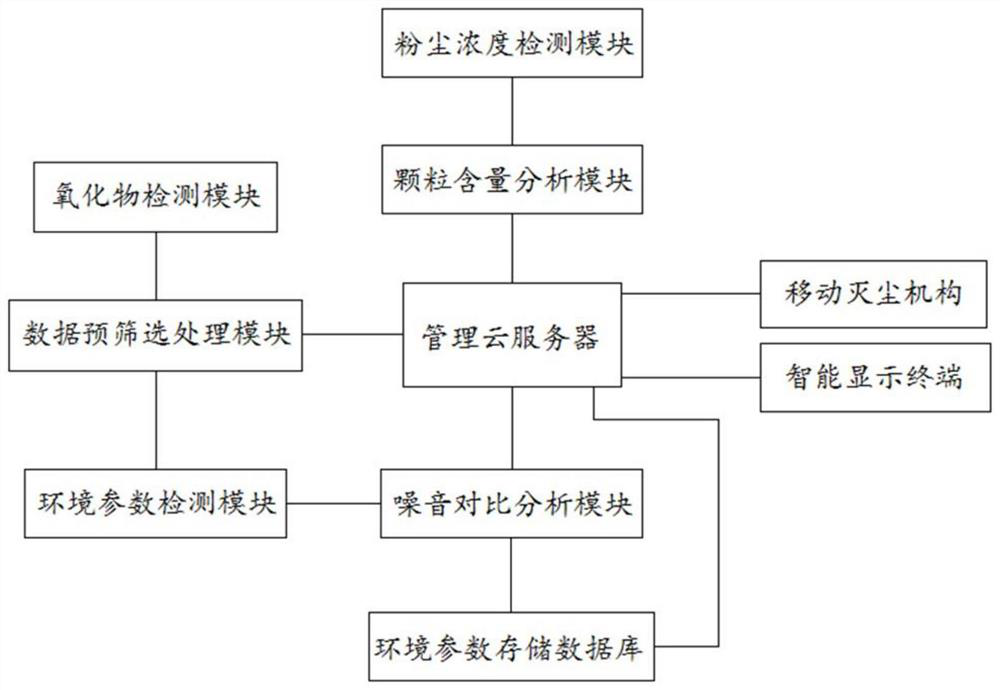

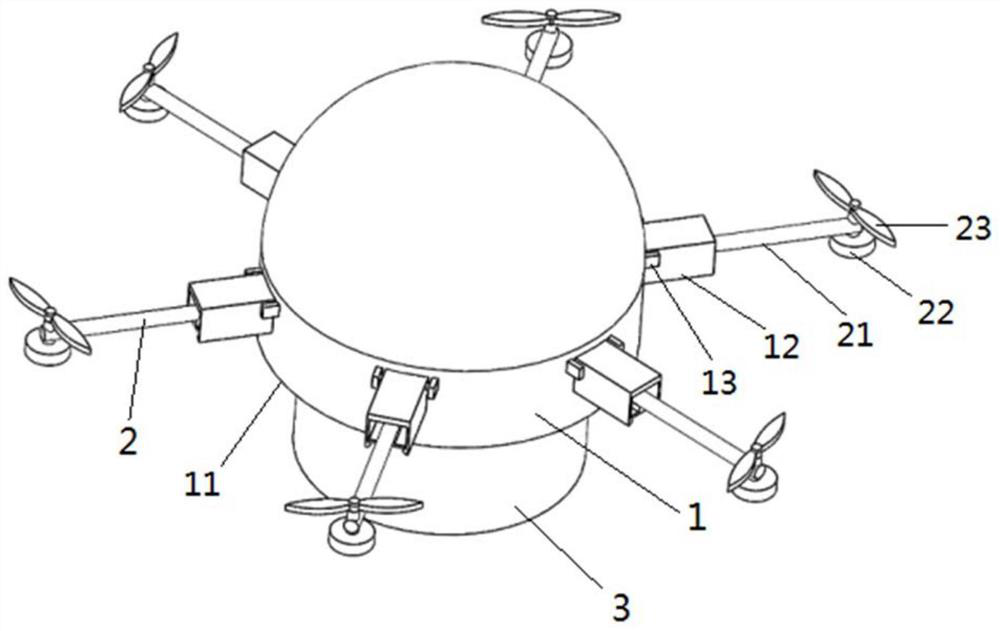

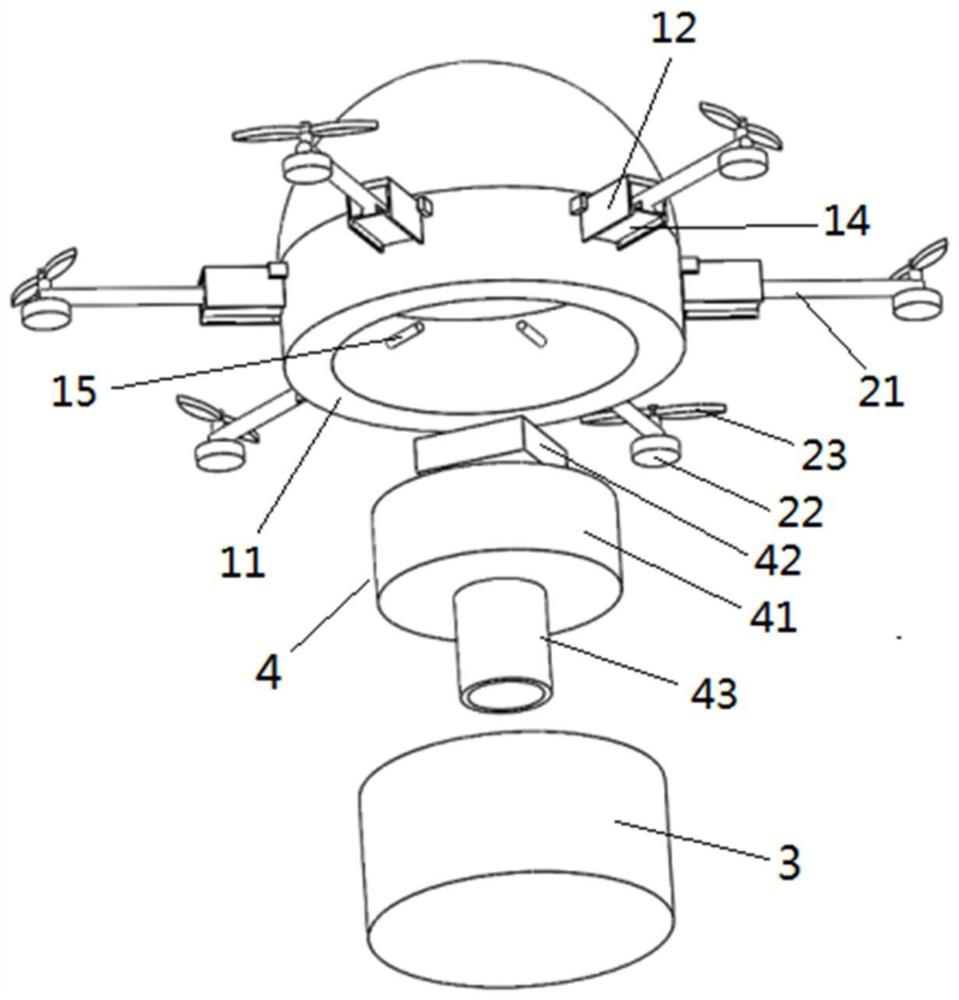

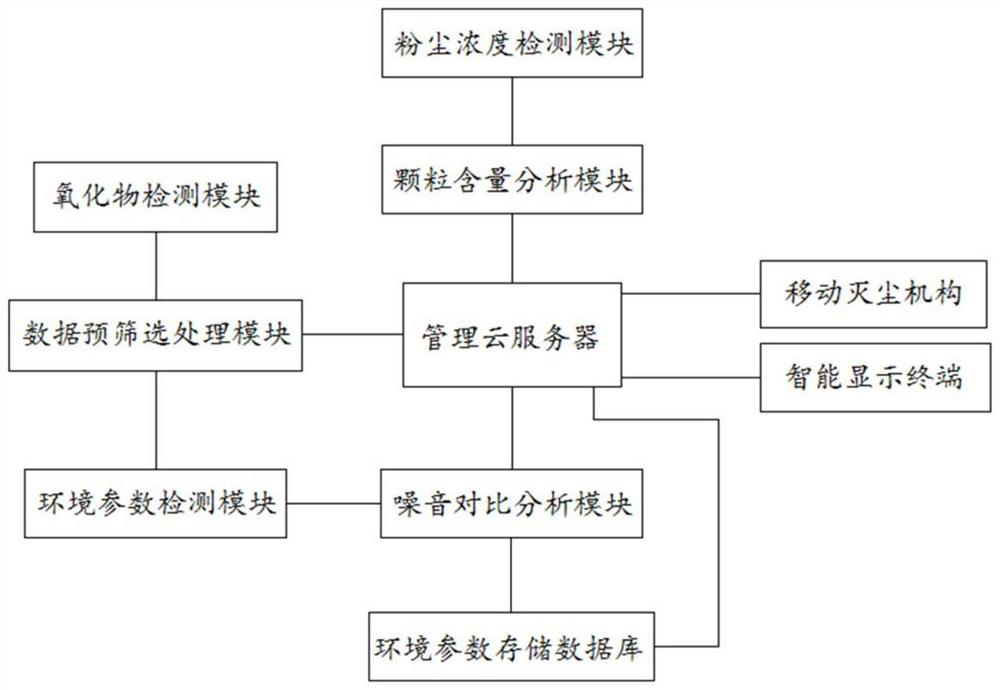

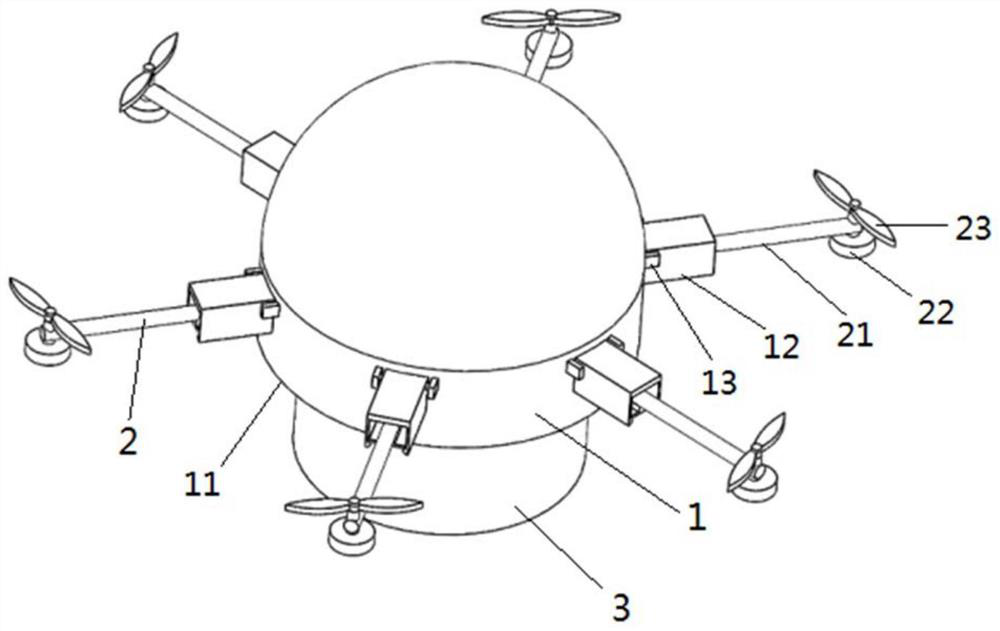

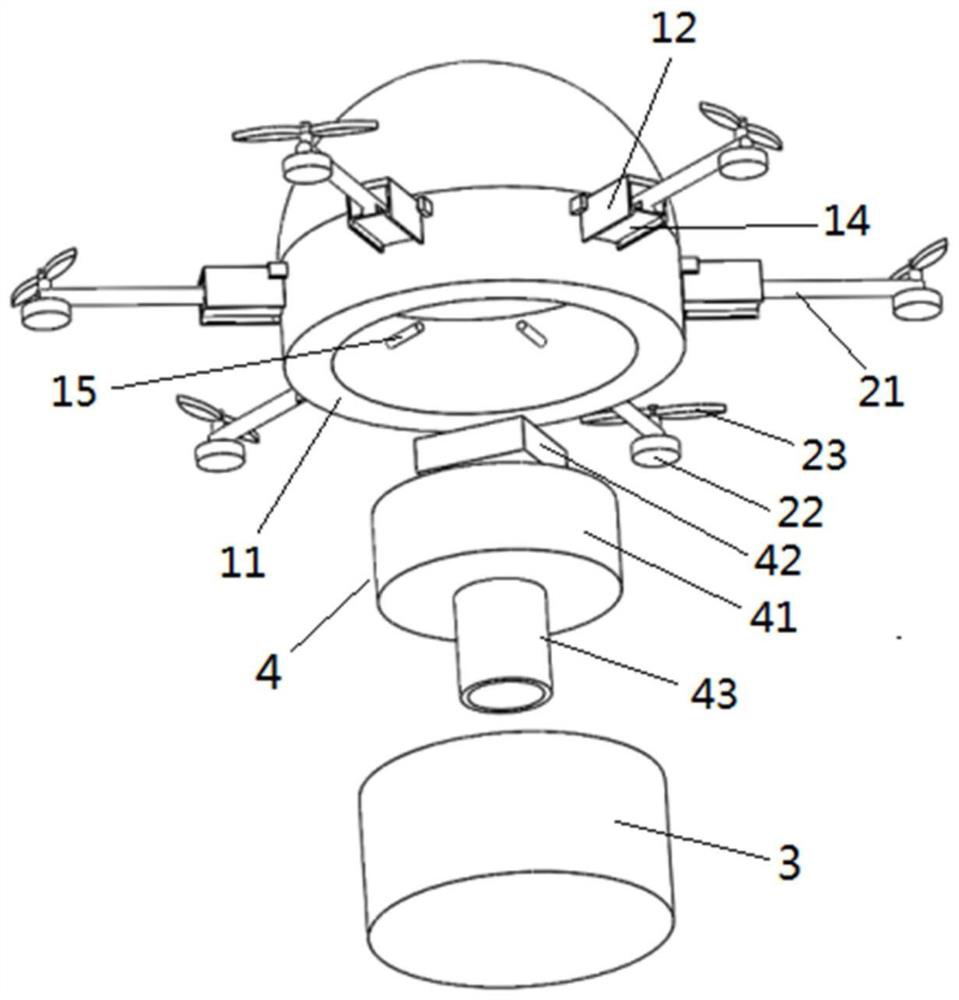

Intelligent environment management system based on Internet of Things

ActiveCN111614755AAccurate predictionImprove accuracyMeasurement devicesParticular environment based servicesAmbient intelligenceInternet of Things

The invention discloses an intelligent environment management system based on the Internet of Things. The system comprises a dust concentration detection module, an oxide detection module, an environment parameter detection module, a noise comparative analysis module, an environment parameter storage database, a particle content analysis module, a data pre-screening processing module, a managementcloud server, an intelligent display terminal and a mobile dust suppression mechanism. According to the invention, whether the dust content and the temperature in the factory reach the explosion danger degree under the combined action can be comprehensively analyzed, and a mode of combining software and hardware is adopted; the mobile dust suppression mechanism is controlled to move to the position of the detection sub-region of which the predicted explosion danger coefficient is greater than a set predicted safety explosion danger coefficient threshold value, so the dust suppression operation is realized, and the explosion risk is reduced; whether the working environment meets the personnel office environment requirements or not can be judged through the statistical working environment matching suppression system, the environmental conditions in the personnel working environment can be visually displayed and analyzed, and the detection accuracy is high.

Owner:广东悦思科技有限公司

Runner preheating cover and runner preheating method

InactiveCN106466710AReduce heat dissipationReduce heat lossMolten metal conveying equipmentsOpen fireEngineering

The invention discloses a runner preheating cover and a runner preheating method. The runner preheating cover comprises a shell and a lining structure. When the shell is preheated, the face, close to a runner, of the shell is the first face, and the first face is provided with a cavity. The lining structure is located in the cavity of the shell. The lining structure internally comprises an electric heater used for generating heat for preheating the runner. The electric heater in the lining structure is used for heating the runner, the runner is preheated, the runner can be subjected to heat preservation through the lining structure and the shell, dissipation of excessive heat in the runner heating process is reduced, heat losses in the runner preheating process are reduced, the runner preheating speed can be increased, the runner preheating time is shortened, and resources and cost are saved. In addition, the electric heater is used for heating the runner, usage of open fire is avoided in the heating process, the service life of a heat preservation material is prolonged, the heat preservation material is prevented from being frequently replaced, garbage generation is reduced, and the runner preheating cover saves more energy and is more environment-friendly.

Owner:宁波创润新材料有限公司

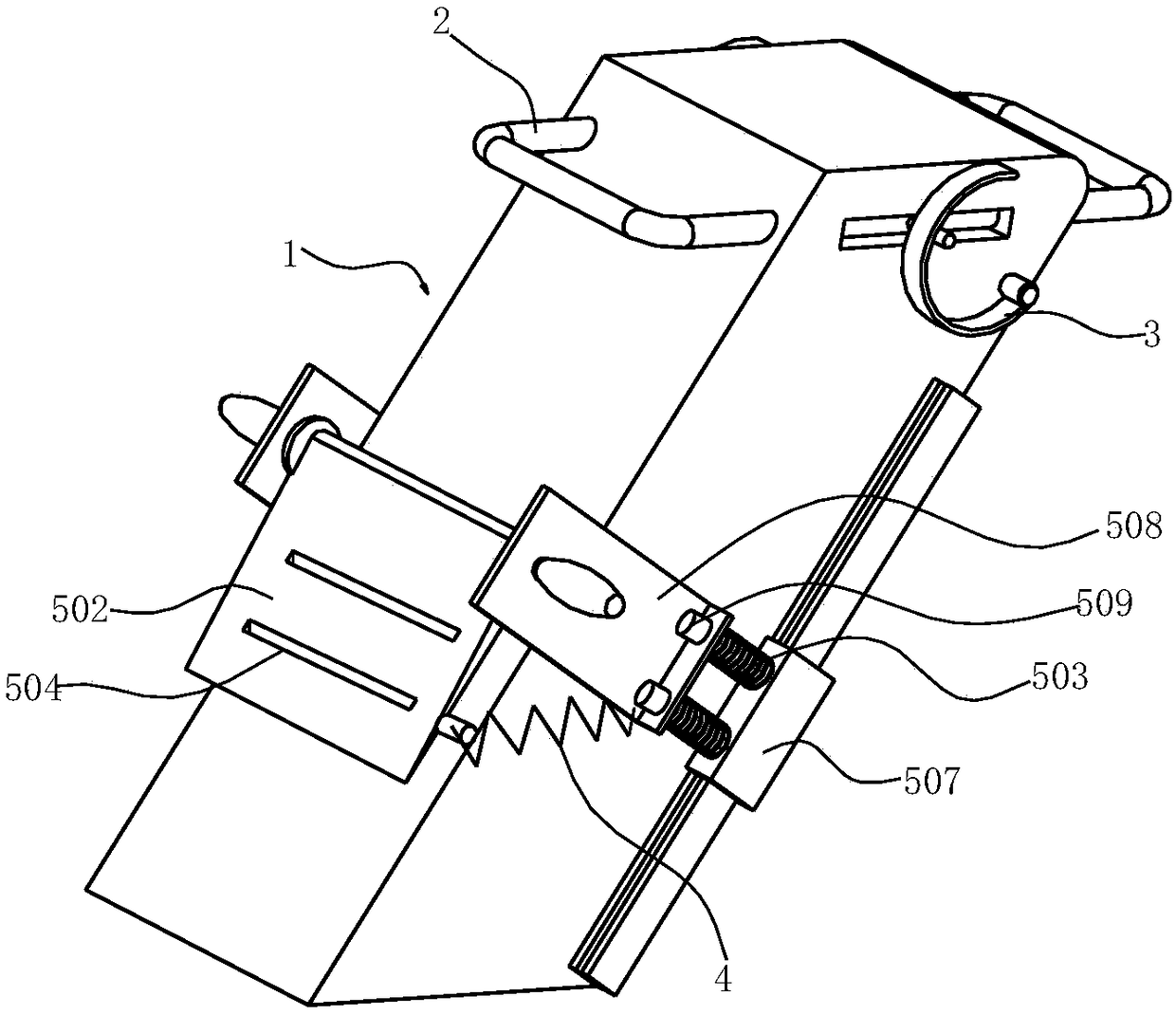

Chinese herb manually planing device and application method thereof

The invention relates to a Chinese herb manually planing device and an application method thereof and belongs to the technical field of Chinese herbal piece slicing equipment. The Chinese herb manually planing device comprises a planing pile, a sliding rack and tension springs, wherein the sliding rack is provided with a pair of guide bars, the end portions of the guide bars are connected througha pressure bar, and each guide bar is provided with a push rod; the left and the right of the upper portion of the planing pile are respectively provided with a bar-shaped hole, and the push rods of the sliding rack are arranged inside the corresponding bar-shaped holes; the tension springs are used for tensioning the push rods so that the pressure bar of the sliding rack can press Chinese herbs arranged on the front surface of the planing pile. According to the Chinese herb manually planing device, an operator manually drives the sliding rack to move forwards and then places the Chinese herbsbetween the sliding rack and the planing pile, and then the sliding rack controlled by the tension spring can press the Chinese herbs onto the planing pile, so that the operator can rapidly and flexibly place Chinese herbs to be clamped, and further the cumbersome operation process in the prior art that Chinese herbs are placed one by one inside a bottomless material box for planing can be simplified.

Owner:安徽新盛中药饮片有限公司

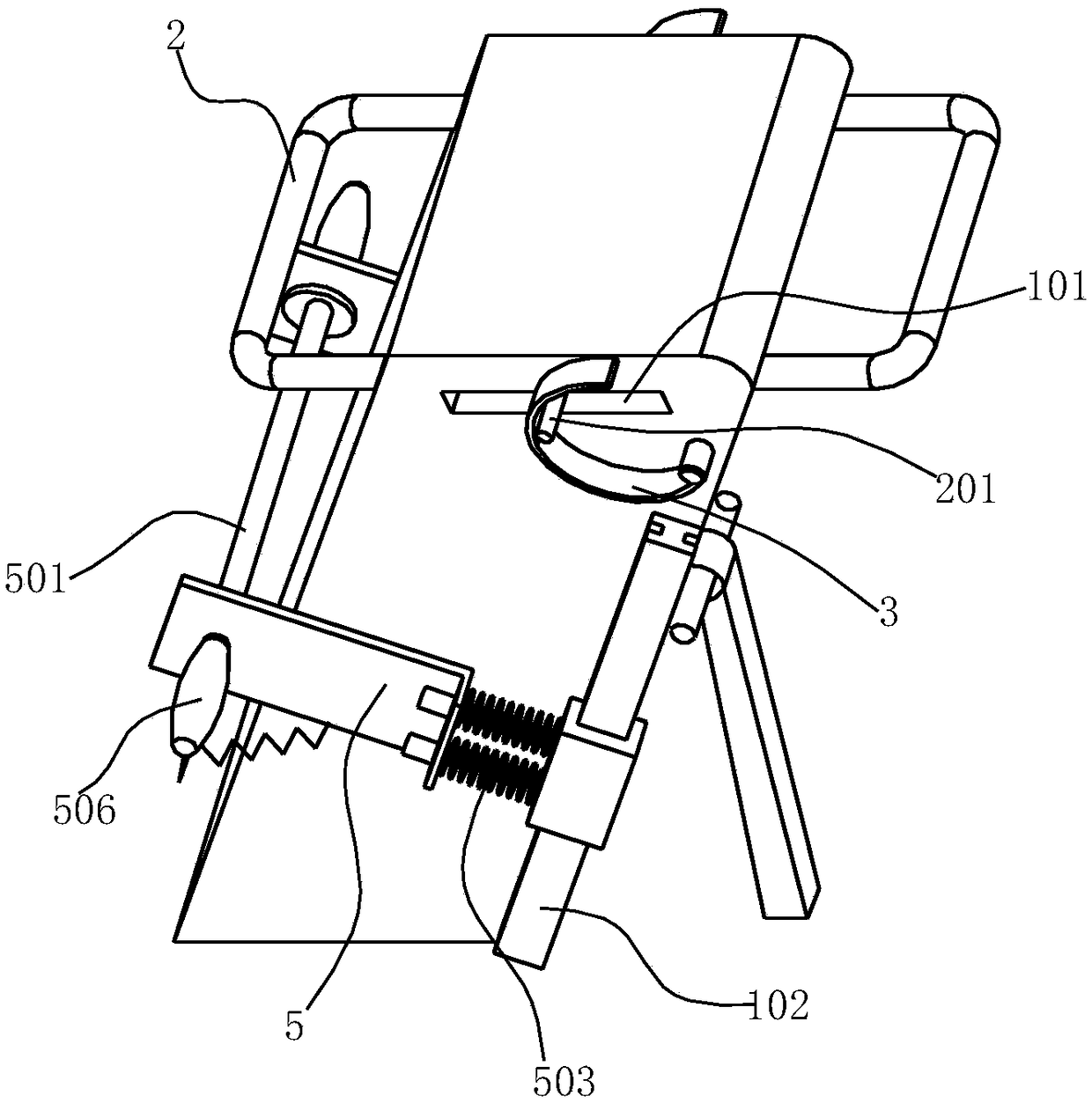

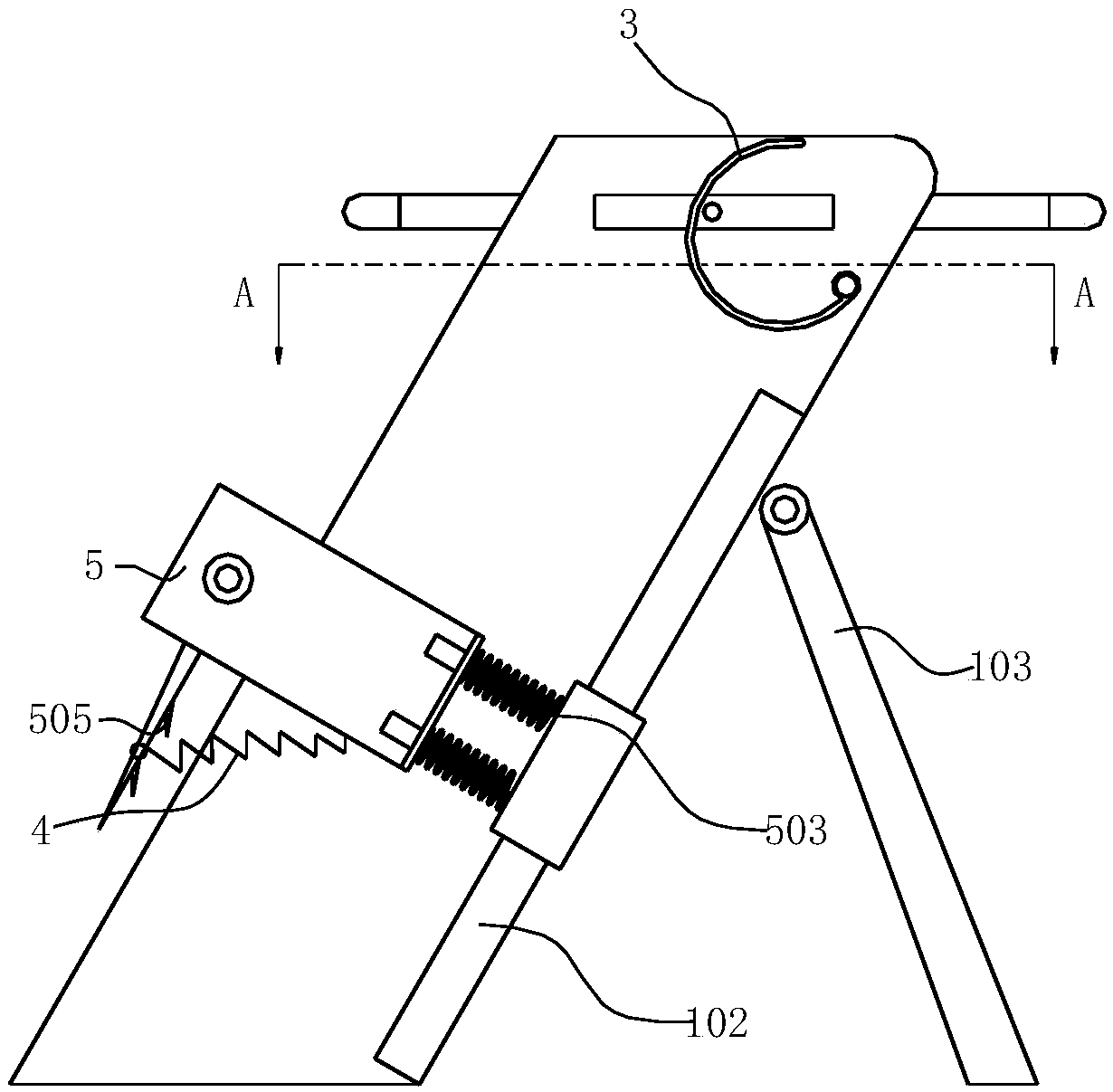

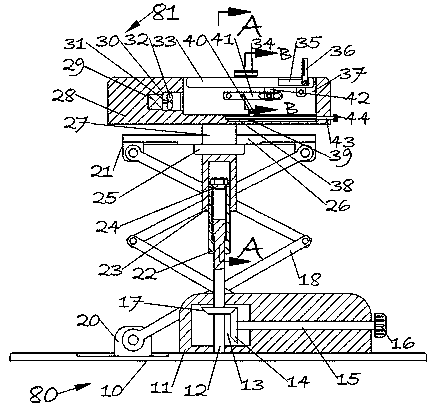

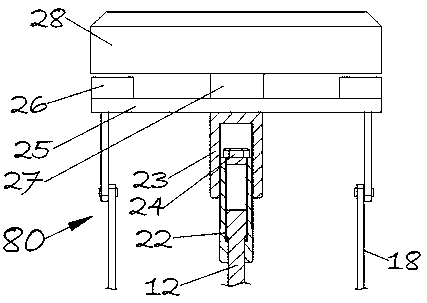

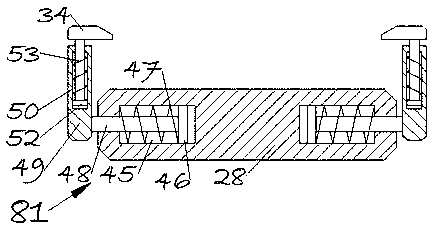

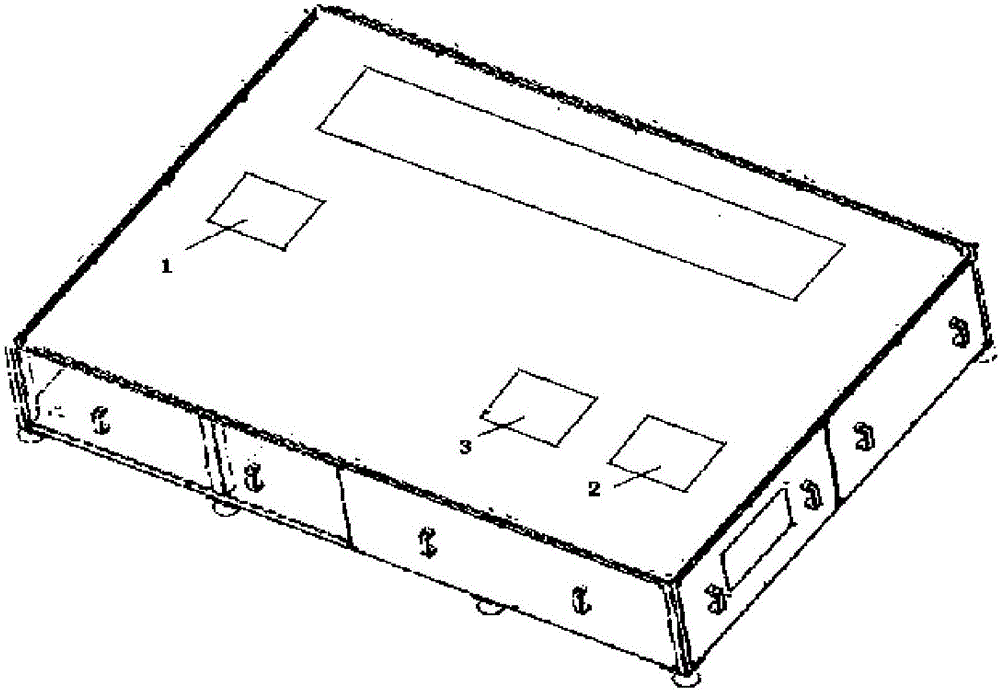

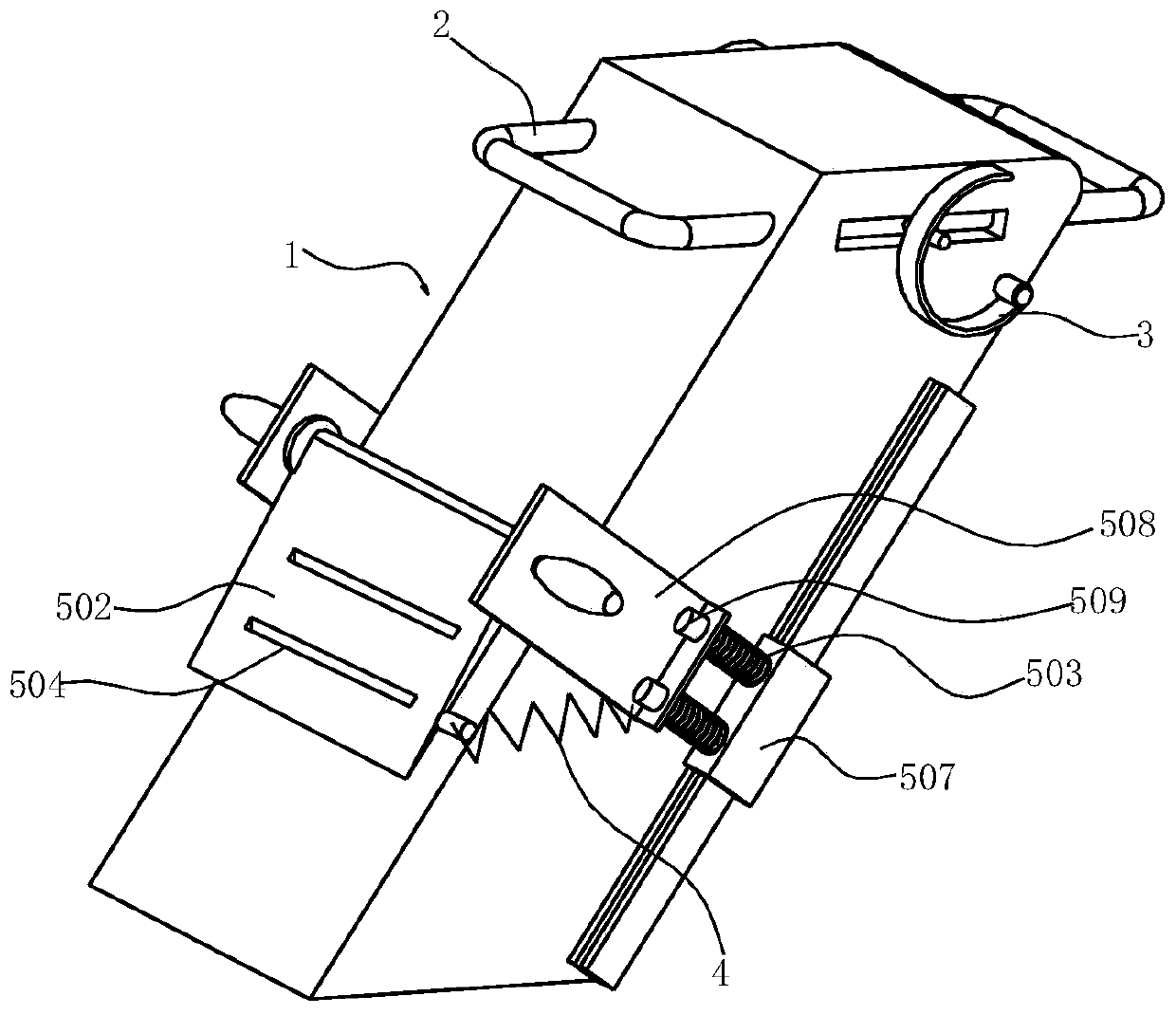

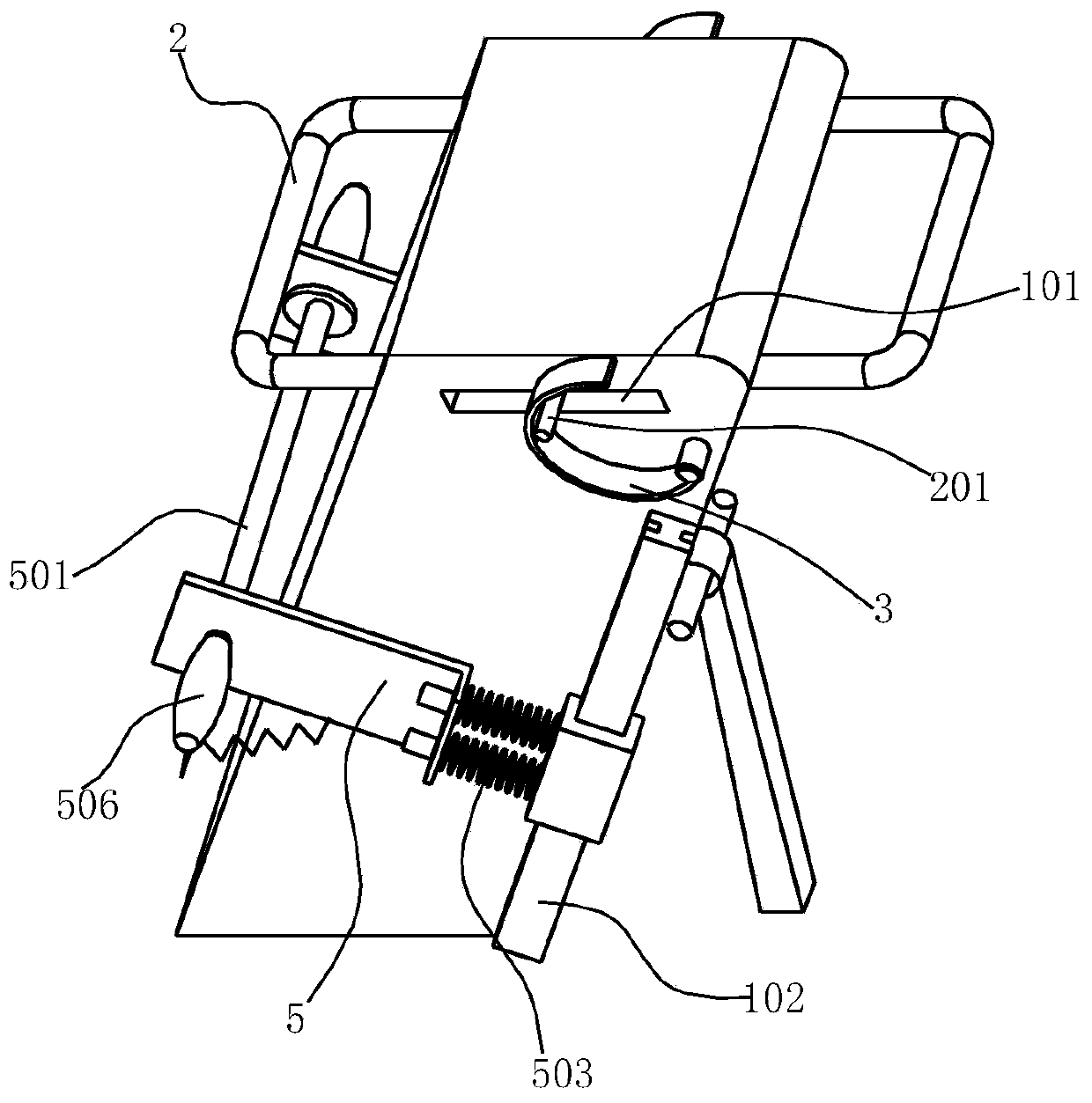

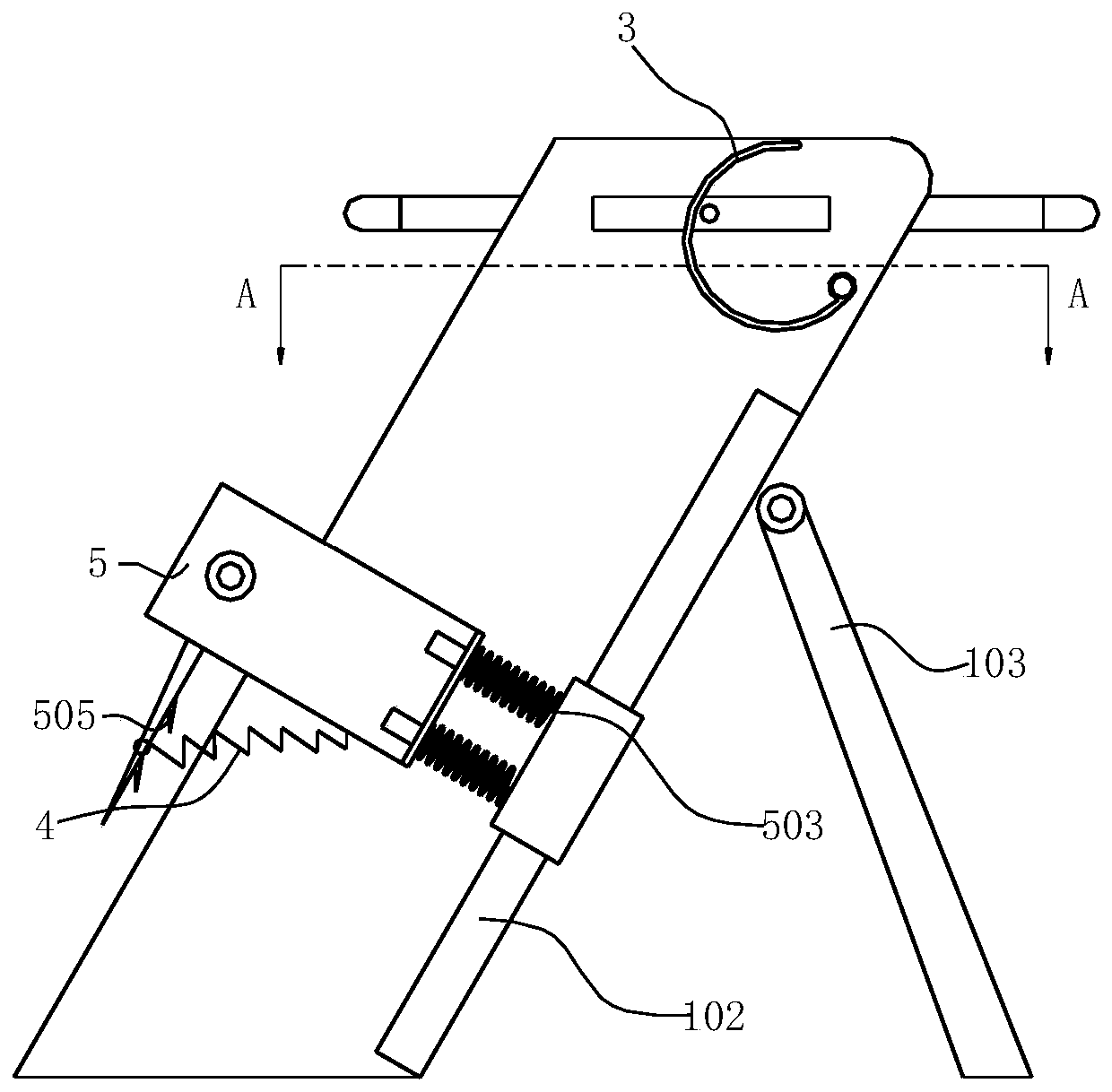

a laptop stand

ActiveCN110260124BHigh strengthEasy to useDigital data processing detailsStands/trestlesSoftware engineeringMechanical engineering

Owner:广西自贸区见炬科技有限公司 +1

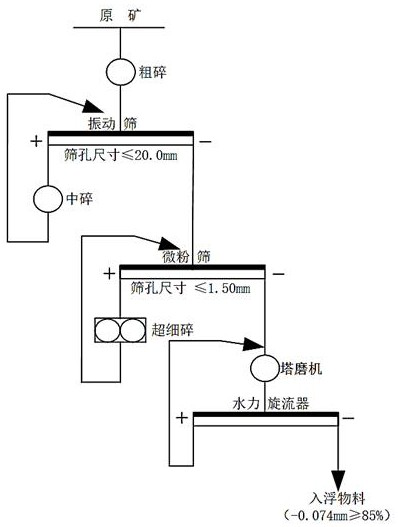

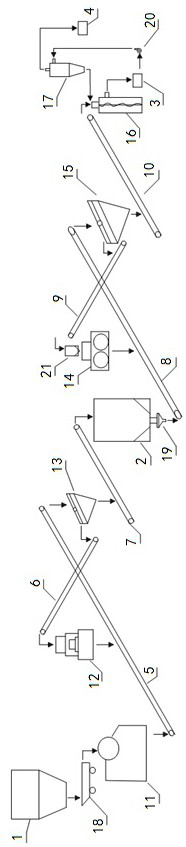

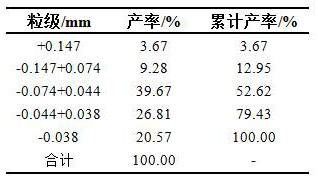

Method and equipment for complex copper-lead-zinc sulfide ore grinding process

InactiveCN111921697AReduced operating power consumptionIncreased operating power consumptionSolid separationSulfidationCrusher

The invention discloses a method and equipment for a complex copper-lead-zinc sulfide ore grinding process. The method comprises the following steps of feeding a coarse crushed material of a jaw crusher into a linear vibrating screen, feeding an oversize material into a cone crusher for crushing, merging the crushed oversize material into the coarse crushed material to form a closed-circuit system, and feeding an undersize material into a stock bin; and feeding the material in the stock bin into a micro-powder sieve, feeding the oversize material into a high-pressure roller mill for ultrafinecrushing and then returns to the micro-powder sieve for feeding to form a closed-circuit system, and the undersize material is a final crushed product. The jaw crusher, the cone crusher, the high-pressure roller mill, the linear vibrating screen and the micro-powder screen form a "three-section two-closed-circuit" process, so that the ore crushing process is enhanced, the granularity of ore grinding materials is reduced, and a final crushed product P95 can be controlled to be 1-2mm; in the first-stage ore grinding, a tower mill and a hydrocyclone are adopted to form a closed circuit; and ore is treated through the three-section two-closed-circuit "ultrafine crushing" and tower grinding combined ore grinding process, and the fineness of the finally floated material can be controlled to be -0.074 mm and is larger than or equal to 85%.

Owner:黑龙江哈工石墨科技有限公司

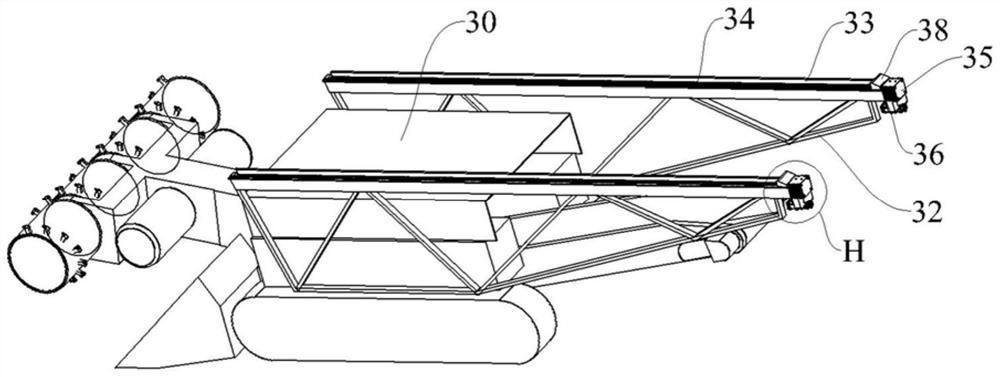

Support dismounting vehicle

ActiveCN114017080ARealize automatic disassemblyAvoid support workVehicle dissasembly recoveryTunnelsAutomationAutomotive engineering

The invention relates to the technical field of roadway support and discloses a support dismounting vehicle. The vehicle comprises a second vehicle body, a second support, second sliding ways, second nut sliding blocks, second lead screws, second driving devices and a mounting arm, wherein the second support is connected with the second vehicle body in a lifting manner; the second sliding ways are connected with the second support and extend in the length direction of the second vehicle body, the number of the second sliding ways is two, and the two second sliding ways are arranged in the width direction of the second vehicle body at intervals; the second nut sliding blocks are arranged in the second sliding ways, and at least part of the second nut sliding blocks are located on the outer side of the second sliding ways; the second lead screws are arranged in the second sliding ways and are in threaded fit with the second nut sliding blocks; the second driving devices are arranged at one ends of the second sliding ways and are connected with the second lead screws; and the mounting arm is used for dismounting a supporting shed frame from the roadway. The supporting shed frame can be automatically disassembled, so automation and unmanned operation during working face tunneling are realized, and construction efficiency can be improved.

Owner:CHINA COAL RES INST

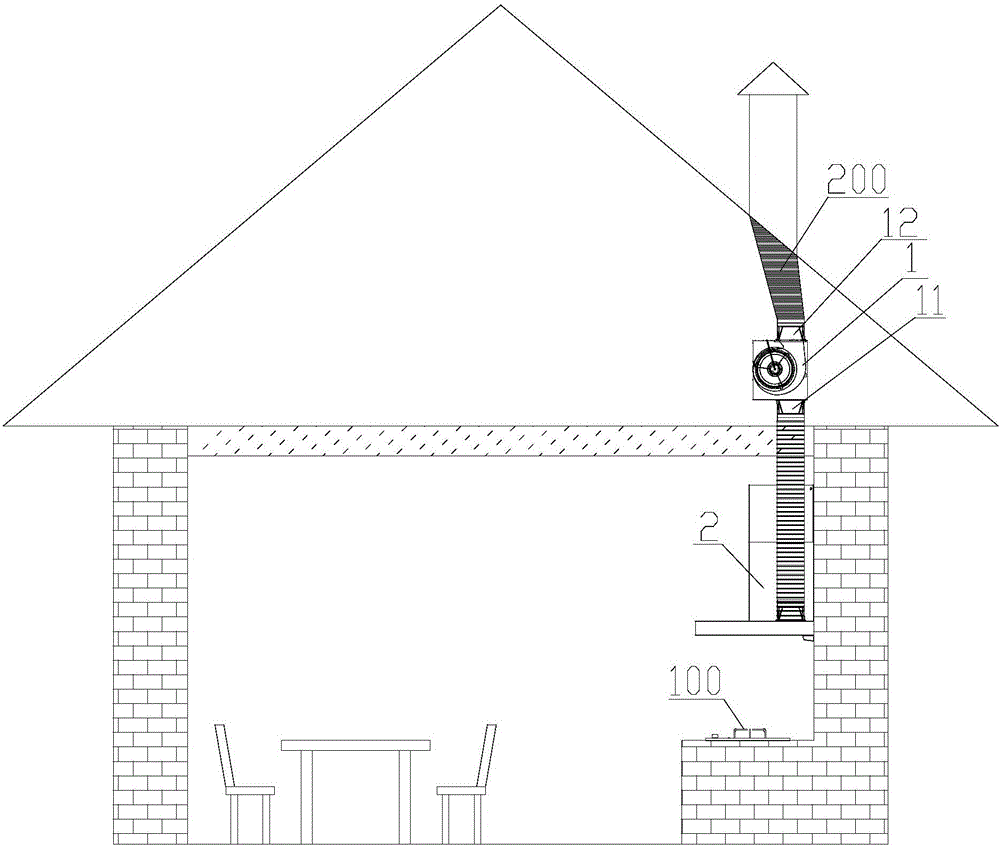

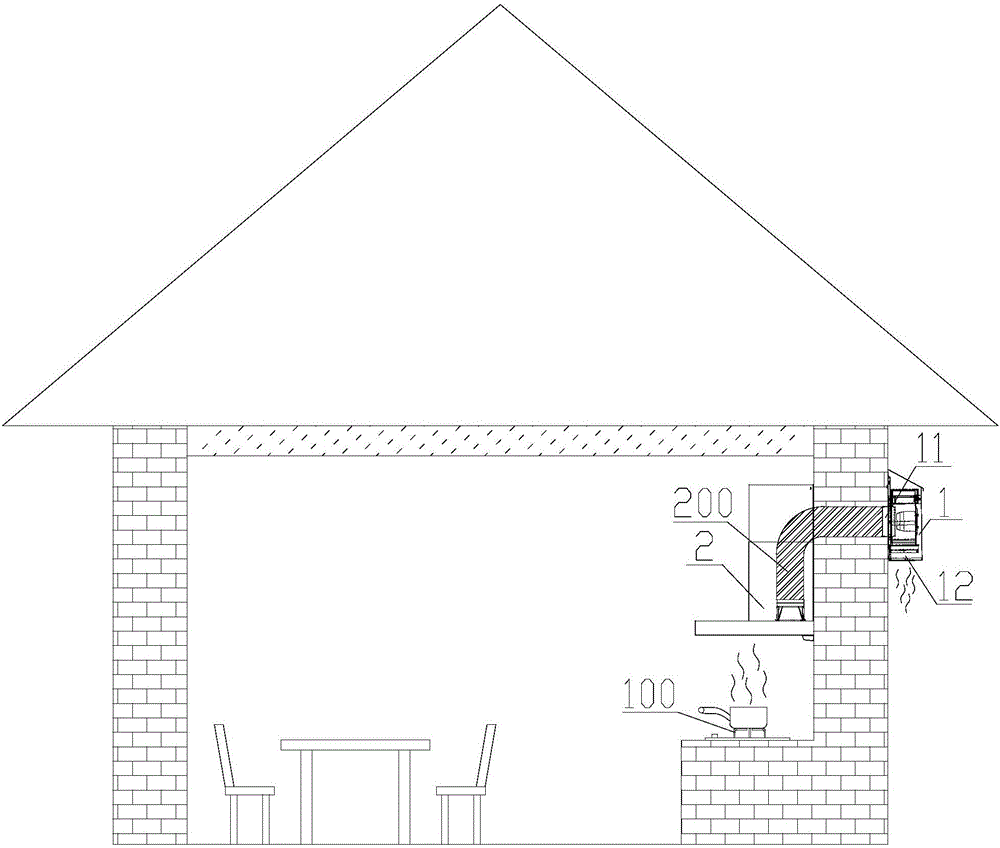

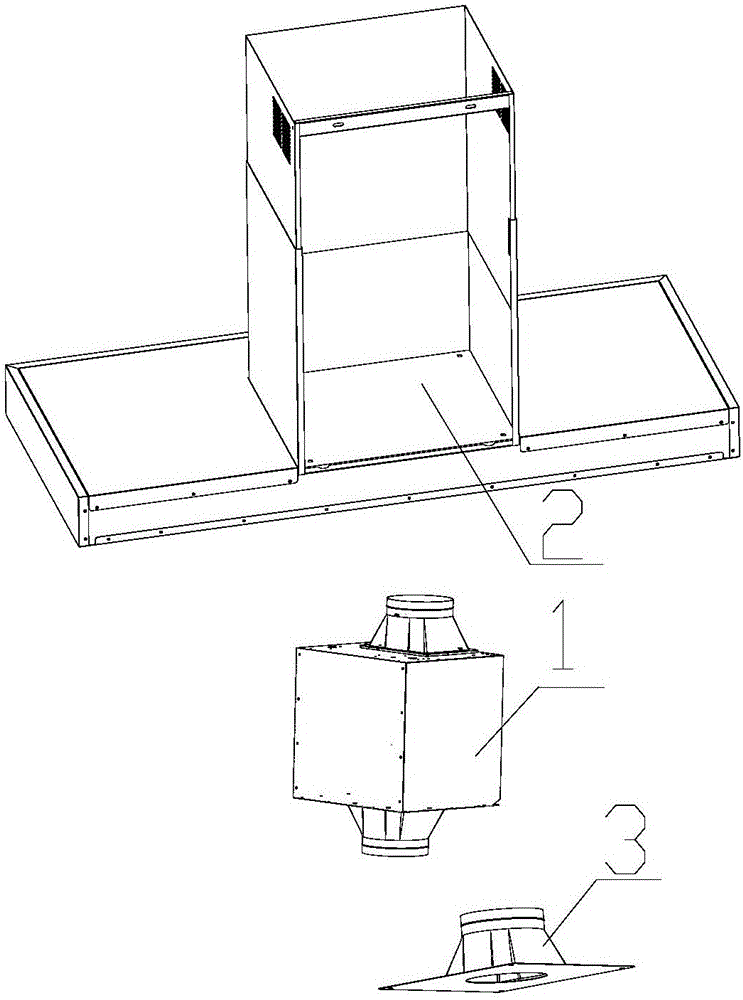

Rang hood with motor mounted in split form

InactiveCN105972668AReduce noiseReduce the risk of occupational diseasesDomestic stoves or rangesLighting and heating apparatusControl theoryOccupational disease

The invention relates to a rang hood with a motor mounted in a split form. The rang hood comprises a motor cabinet and a machine body, wherein the motor is mounted in the motor cabinet; the machine body is capable of accommodating the motor cabinet; the machine body is mounted above a stove in a kitchen; the motor cabinet is mounted on an oil smoke discharging flue outside the kitchen. Due to the split mounting, the motor which generates noise is arranged in the space outside the kitchen, the noise of the range hood is greatly reduced, the cooking environment is optimized, and especially, the occupational disease risk caused by the noise to the professional cooking people is reduced. The cooking people can select the motors in different power according to the requirement, such as, high power motor for increasing the suction and quickening the smoke discharging.

Owner:珠海欧姆斯厨房电器有限公司

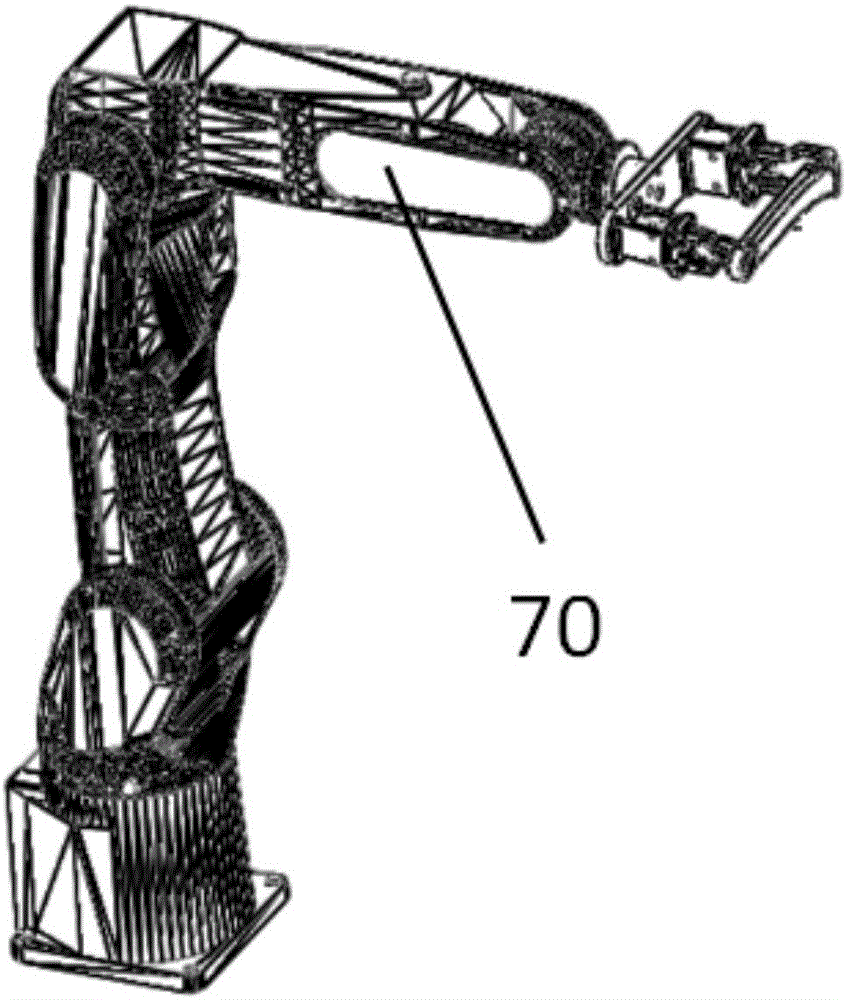

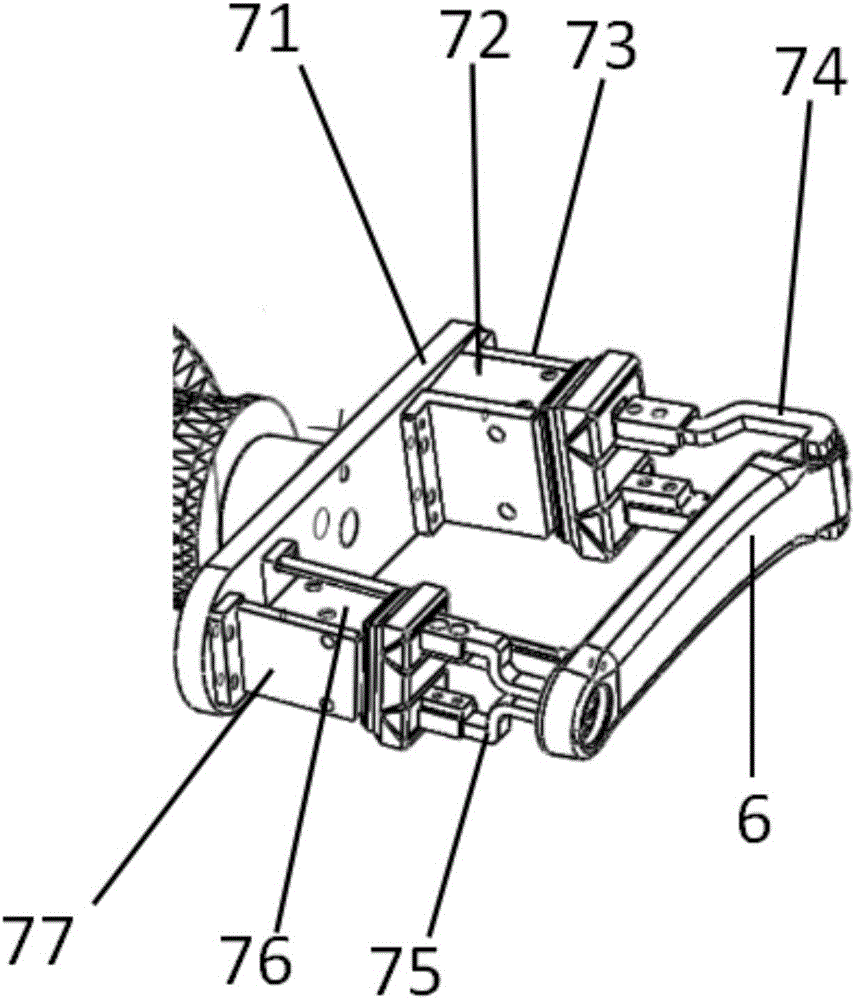

Connector component surface polishing robot for automobile windscreen wiper system

ActiveCN106312770AImprove grinding efficiencyGuaranteed stabilityGrinding machinesGrinding headsWindscreen wiperMachine control

The invention discloses a connector component surface polishing robot for an automobile windscreen wiper system. The connector component surface polishing robot mainly comprises a component surface polishing robot body, a six-axis machine control system, a grinding module, a fine polishing module and a rough polishing module. The grinding module, the rough polishing module and the fine polishing module are arranged on a tabletop of the component surface polishing robot body. The rough polishing module is arranged on the right side of the grinding module. The fine polishing module is arranged on the right side of the rough polishing module. The grinding module is arranged on the left side of the rough polishing module. The fine polishing module and the rough polishing module are provided with six-axis machine systems correspondingly. The six-axis machine control system is arranged in a lower-layer control cabinet of the robot. Annular abrasive belts of the connector component surface polishing robot for the automobile windscreen wiper system are arranged on rolling wheels correspondingly, through driving of drive wheels, a tension device and a motor on a front driven wheel are utilized, the environment of the work field is improved, and unmanned operation and intelligence are achieved.

Owner:NINGBO ASIAWAY AUTOMOTIVE COMPONENTS CO LTD

Tire tube rubber

The invention discloses a tire tube rubber which is prepared from the following raw materials in percentage by weight: 10-30 percent of natural rubber, 30-70 percent of reclaimed rubber, 3-5 percent of a rubber accelerator, 5-8 percent of metallic oxide, 3-6 percent of stearic acid, 1-3 percent of 4010NA1, 1-2 percent of PM1, 0.5-2 percent of tall oil, 1-3 percent of rosin, 1-3 percent of a rubber smell-covering agent and the balance of reinforcing filler. According to the tire tube rubber, damage of carbon black to the respiratory system of an operator is effectively avoided, the risk of suffering from occupational diseases by production personnel is reduced, the odor of rubber is reduced, the ageing resistance, compression resistance and impact resistance of the rubber are greatly improved, the environmental pollution is avoided, the service life of the tire rube is prolonged, and the service safety of the tire tube is improved.

Owner:JIAOZUO CITY HONGCHANG PLASTIC IND

Stamping edging device without need of manual polishing

The invention relates to a stamping edging device without the need of manual polishing, which comprises a lower mould, an upper mould, a pressurizing device and a cutter, wherein the upper mould is arranged above the lower mould for a certain distance in an up and down moving mode, and the bottom is provided with a cutter mounting rack; the pressurizing device is arranged on the upper part of the upper mould, and is provided with a controller; and the cutter is vertically arranged at one side of the mounting rack on the upper mould, and a sawtooth-shaped grinding mouth is formed at the lower part of the outer side edge of the cutter. In the stamping edging device without the need of manual polishing provided by the invention, material traps on the surface of a demoulded product are removed by the up and down reciprocating movement of the cutter with the sawtooth-shaped grinding mouth, and deckle edges are polished to be smooth. Because manual polishing is not needed, the number and the labor intensity of operators can be greatly reduced, the production efficiency is high, environment pollution can be reduced, and the risk of suffering from occupational diseases for the operators is reduced.

Owner:TIANJIN TOYODA GOSEI CO LTD

Chinese herbal medicine manual planing device and using method thereof

ActiveCN108214623BFlexible placementSimplify one by oneMetal working apparatusEngineeringMechanical engineering

The invention relates to a Chinese herb manually planing device and an application method thereof and belongs to the technical field of Chinese herbal piece slicing equipment. The Chinese herb manually planing device comprises a planing pile, a sliding rack and tension springs, wherein the sliding rack is provided with a pair of guide bars, the end portions of the guide bars are connected througha pressure bar, and each guide bar is provided with a push rod; the left and the right of the upper portion of the planing pile are respectively provided with a bar-shaped hole, and the push rods of the sliding rack are arranged inside the corresponding bar-shaped holes; the tension springs are used for tensioning the push rods so that the pressure bar of the sliding rack can press Chinese herbs arranged on the front surface of the planing pile. According to the Chinese herb manually planing device, an operator manually drives the sliding rack to move forwards and then places the Chinese herbsbetween the sliding rack and the planing pile, and then the sliding rack controlled by the tension spring can press the Chinese herbs onto the planing pile, so that the operator can rapidly and flexibly place Chinese herbs to be clamped, and further the cumbersome operation process in the prior art that Chinese herbs are placed one by one inside a bottomless material box for planing can be simplified.

Owner:安徽新盛中药饮片有限公司

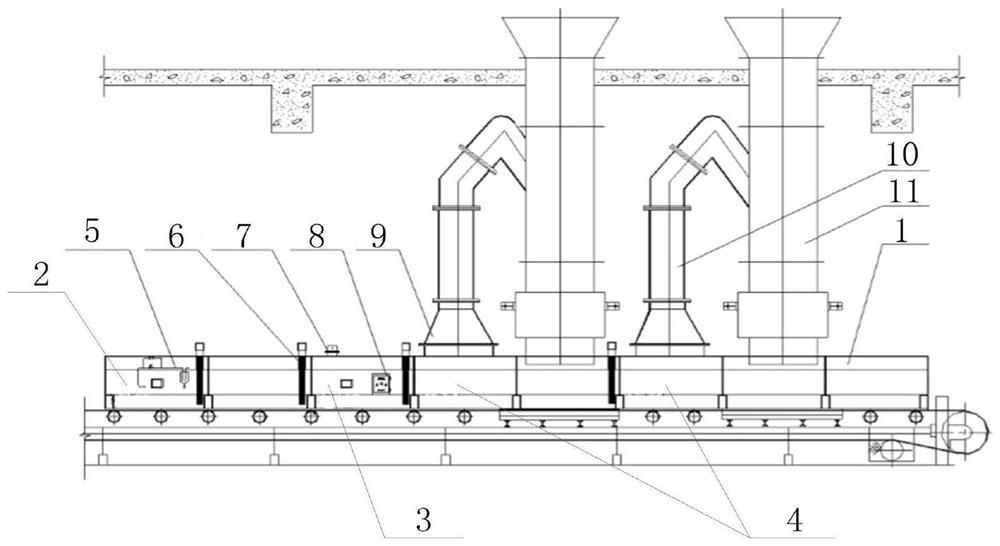

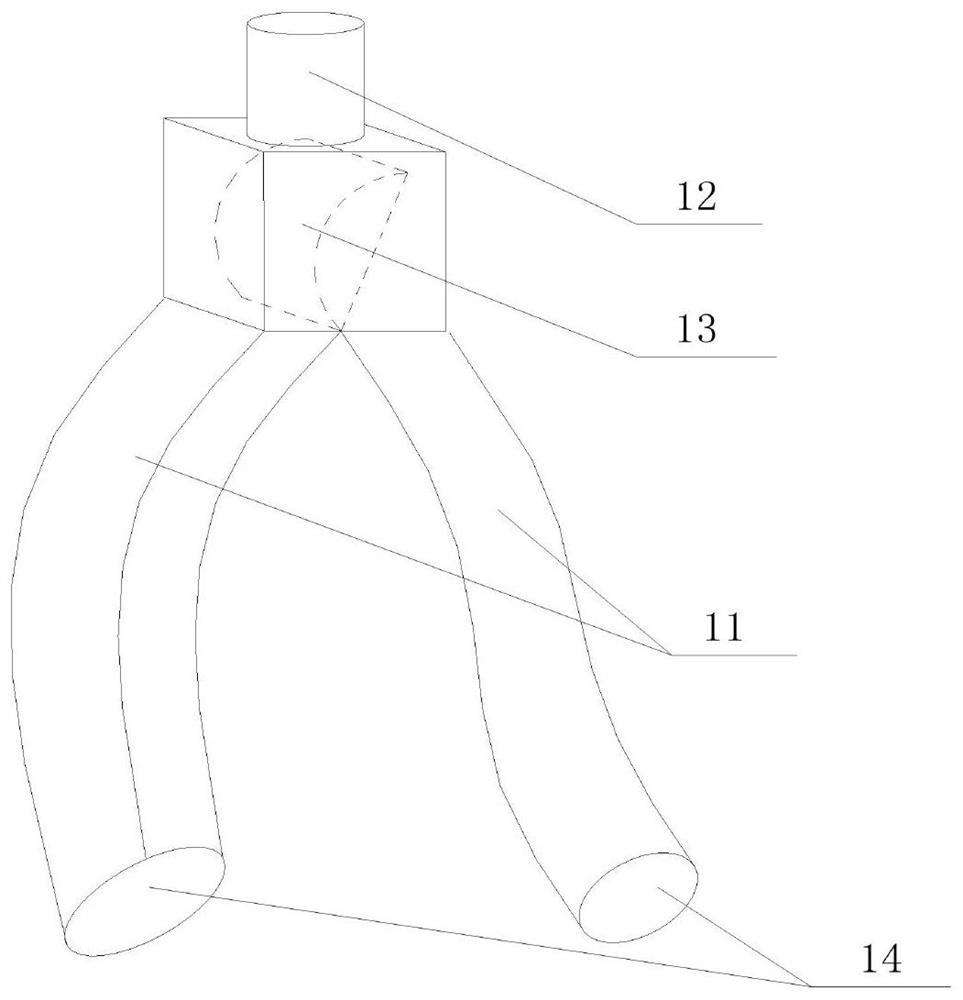

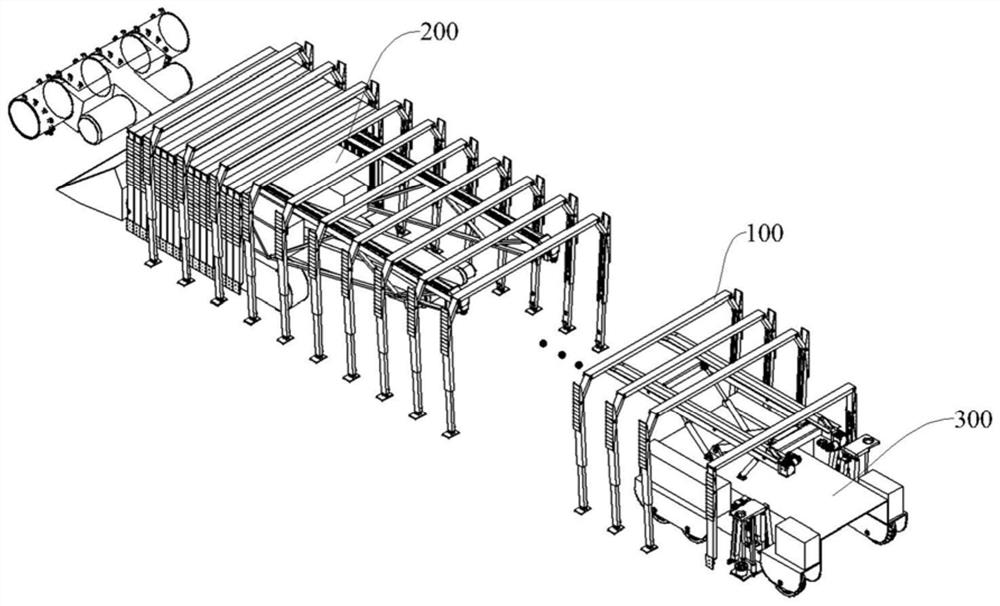

A fully enclosed coal conveying system for a thermal power plant

ActiveCN111891780BImprove the frequency of coal blockingNo high angle collisionLoading/unloadingPower stationSprayer

The invention discloses a fully enclosed coal conveying system for a thermal power plant, which is characterized in that it includes a material guide trough, a return pipe, and a material drop tube, the material drop tube is arranged at the upper part of one end of the material guide trough, and the material drop The pipe communicates with the inside of the guide trough, and the inside of the guide trough is provided with a buffer zone, an inspection area, and a purification area. A return pipe is provided above, and a collector is provided at the bottom of the return pipe, and the collector is installed on the top of the buffer zone. A detection device and a control box are provided in the inspection area, and a spray nozzle is provided in the purification area. shower system. In actual use, the system can reduce the risk of safety accidents caused by operators cleaning and dredging the coal fall, improve the coal handling environment, and reduce the risk of occupational diseases.

Owner:ORDOS JUNZHENG ENERGY CHEM

Intelligent glass fiber forming and winding equipment

An intelligent glass fiber forming and winding device comprises a winding head and a tube changing mechanism installed on a main frame, wherein the tube changing mechanism comprises a rotating disk and a yarn guide, at least one yarn winding tube is sleeved on the winding head and comprises a winding section and a tube changing section, and the tube changing section can be used to cut off and windthe yarn; the yarn guide can rotate clockwise or counterclockwise relative to the main frame and comprises a yarn guide rotating shaft and a tube changing yarn guiding rod and a loading yarn guidingrod that are fixed on the yarn guide rotating shaft, and both ends of the tube changing yarn guiding rod are inconsistent with respect to the axis of the yarn guide rotating shaft such that the yarn guide rotating shaft rotates during the tube changing process, and the yarn can slide from the highest end to the lowest end along the tube changing yarn guiding rod, thereby poking the yarn to the tube changing section on the corresponding winding tube. The intelligent glass fiber forming and winding device provided by the invention has reasonable structure and easy operation, and can effectivelyimprove the production efficiency and product quality of glass fiber.

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

A kind of environment intelligent management system based on Internet of things

ActiveCN111614755BAccurate predictionImprove accuracyMeasurement devicesParticular environment based servicesIntelligent environmentEnvironmental resource management

The invention discloses an intelligent environment management system based on the Internet of Things. The system comprises a dust concentration detection module, an oxide detection module, an environment parameter detection module, a noise comparative analysis module, an environment parameter storage database, a particle content analysis module, a data pre-screening processing module, a managementcloud server, an intelligent display terminal and a mobile dust suppression mechanism. According to the invention, whether the dust content and the temperature in the factory reach the explosion danger degree under the combined action can be comprehensively analyzed, and a mode of combining software and hardware is adopted; the mobile dust suppression mechanism is controlled to move to the position of the detection sub-region of which the predicted explosion danger coefficient is greater than a set predicted safety explosion danger coefficient threshold value, so the dust suppression operation is realized, and the explosion risk is reduced; whether the working environment meets the personnel office environment requirements or not can be judged through the statistical working environment matching suppression system, the environmental conditions in the personnel working environment can be visually displayed and analyzed, and the detection accuracy is high.

Owner:广东悦思科技有限公司

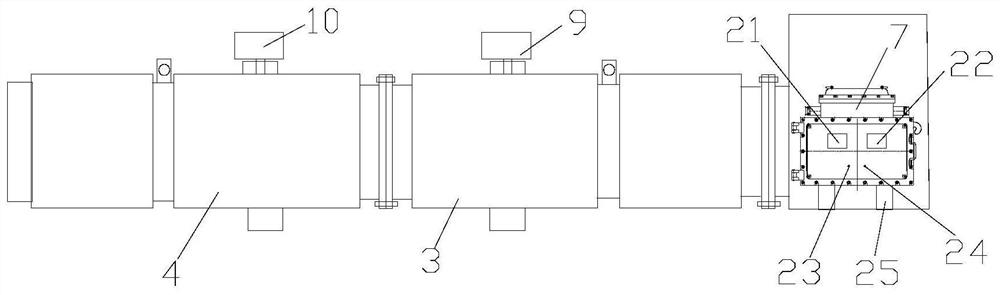

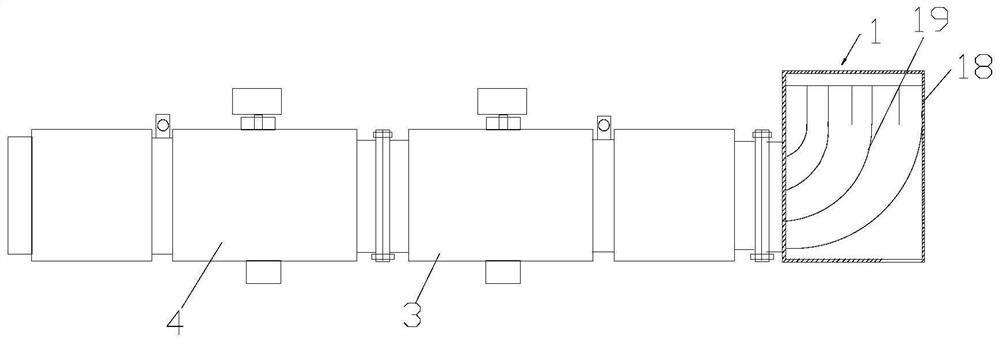

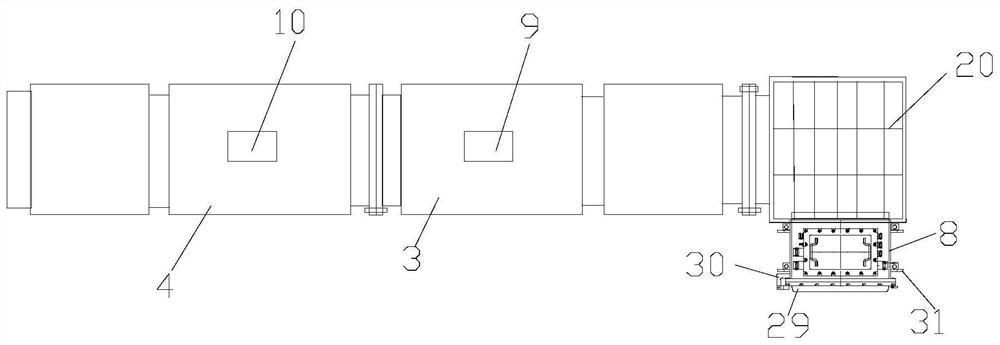

Noise reduction and ventilation control device used under mine

PendingCN112761702AGuaranteed by air volumeGuaranteed air volumeMining devicesPump componentsFrequency changerAir volume

The invention discloses a noise reduction and ventilation control device used under a mine. The noise reduction and ventilation control device comprises a noise reducer, an explosion-proof controller, a main fan, a standby fan, a PIC single chip microcomputer and a frequency converter, wherein the standby fan is connected with the main fan; the noise reducer is installed on the air inlet side of the main fan; the explosion-proof controller comprises an upper box body and a lower box body; the PIC single chip microcomputer is installed on the lower box body; the main fan and the standby fan are connected with a first motor and a second motor respectively; and the frequency converter is electrically connected with the first motor and the second motor. According to the noise reduction and ventilation control device, the airflow disturbance factor caused in the air flowing process is overcome, air noise caused by airflow disturbance is effectively avoided, intelligent control is achieved by installing an intelligent fan control device, the air volume supplied to the working face by the fans is the optimal air volume, the operation cost can be greatly saved, noise generated by long-time full-load operation can be effectively avoided, and meanwhile the operation safety of the working face can be ensured.

Owner:XINJIANG INST OF ENG

Airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device

ActiveCN103505371BEffective controlReduce frequent cloggingPharmaceutical product form changeTowerPollution

The invention discloses an airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device which is simple and reasonable in structure, airtight and free of pollution in the whole process and high in automation degree. The airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device comprises a material drying boiling cavity, a granule arranging system and a corresponding control device. The material drying boiling cavity is a tower type integrated drying boiling cavity which comprises an air inlet system, a granulation material bucket component, a middle bucket body component and an air exhausting dust removal system. A material conveying system is arranged between the granule arranging system and the tower type integrated drying boiling cavity, and the material conveying system comprises a conveying channel between the tower type integrated drying boiling cavity and the granule arranging system.

Owner:YICHUN WANSHEN PHARMA MACHINERY

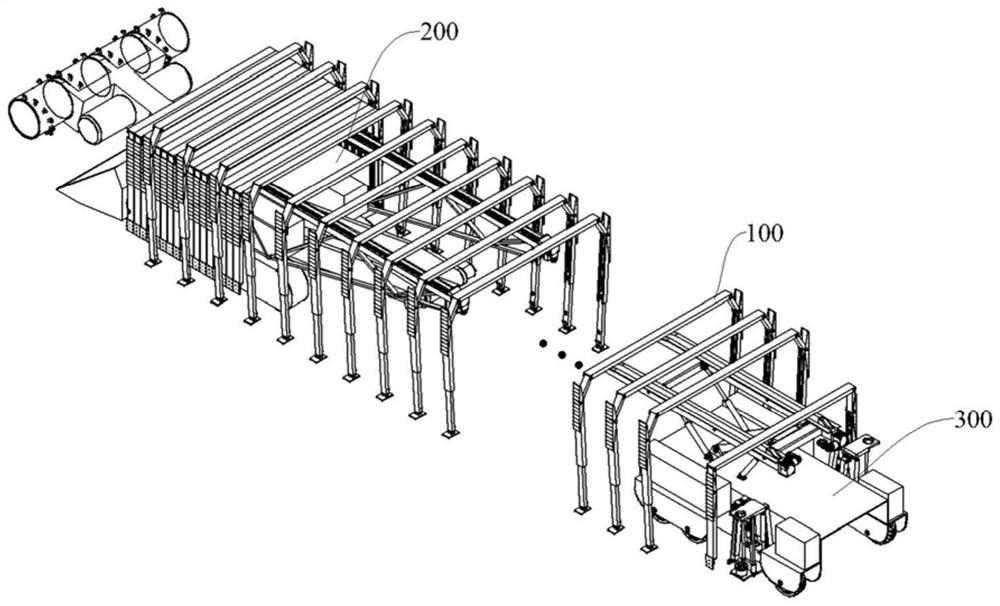

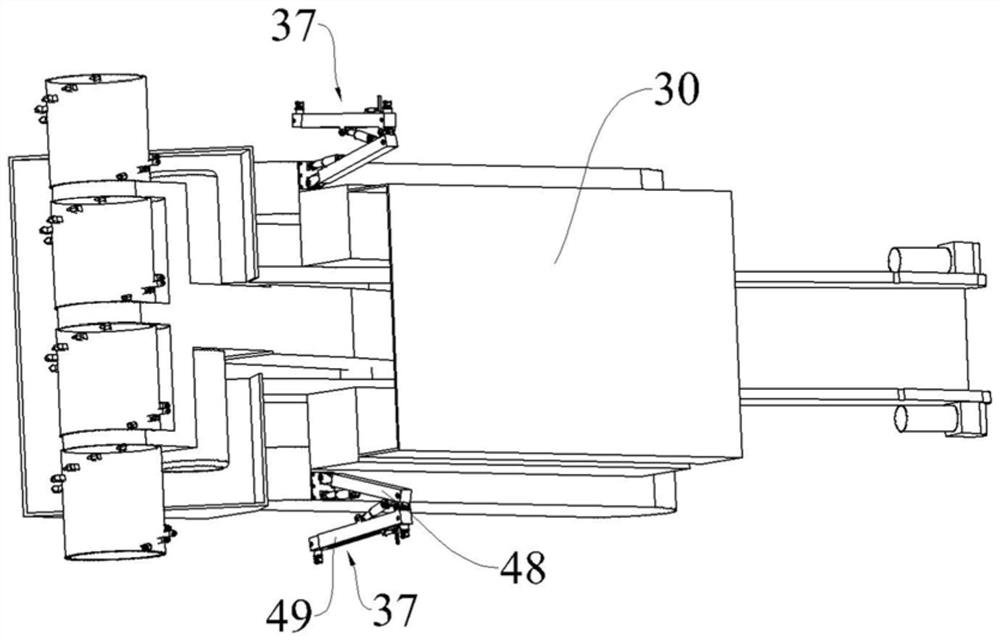

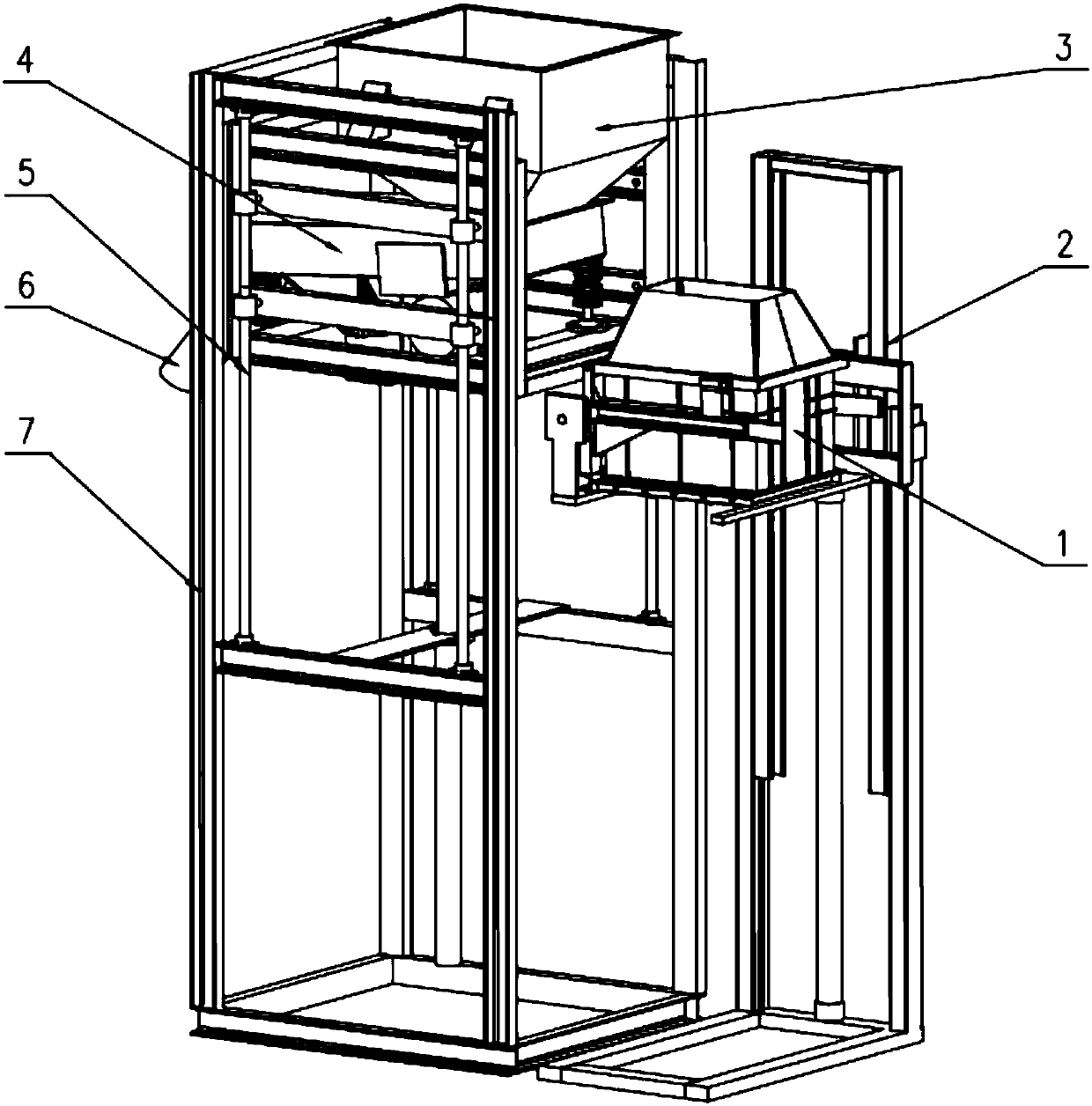

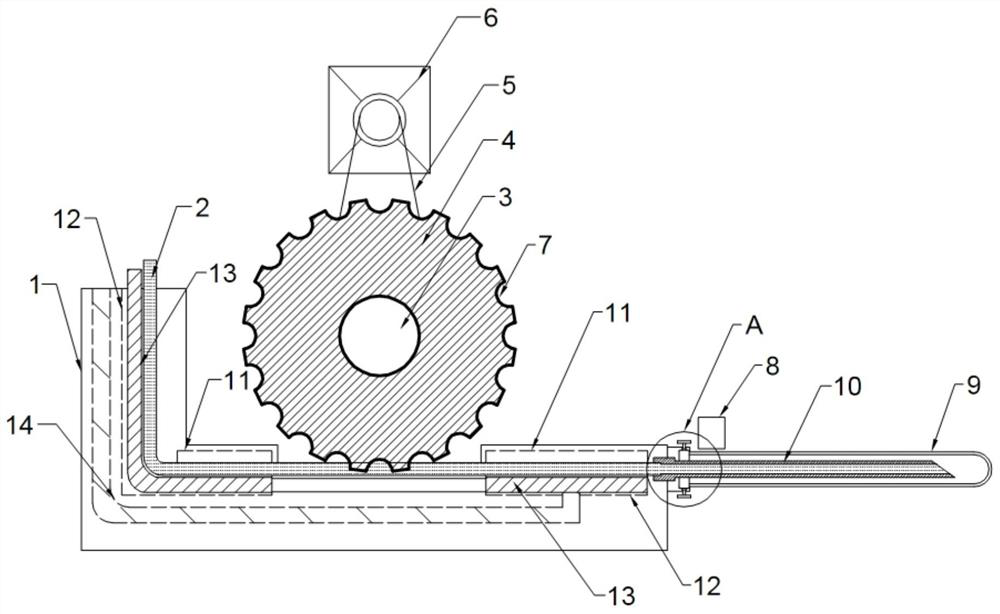

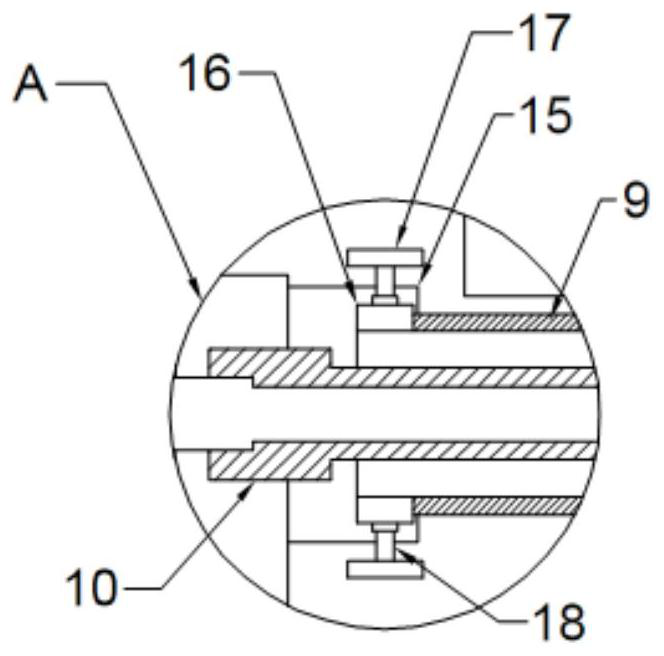

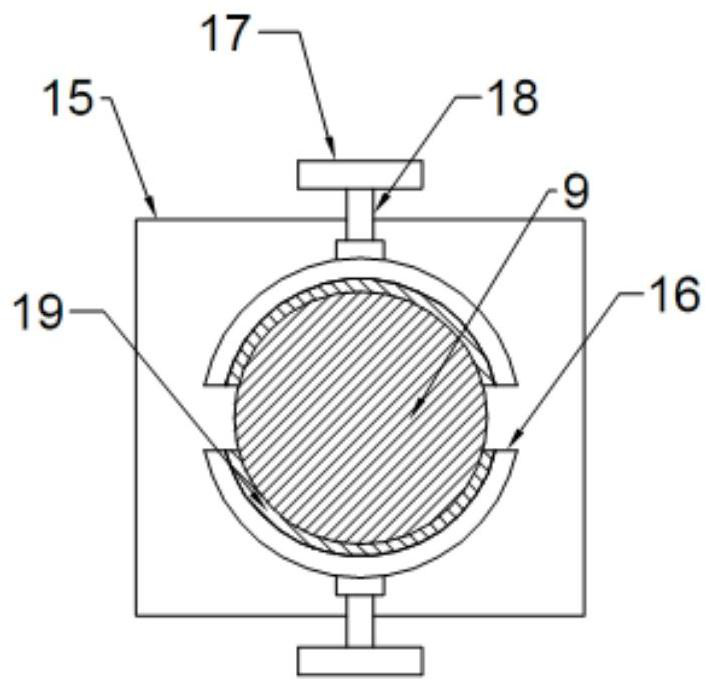

Large-thermal-field automatic loading device and method

InactiveCN109795859ASolve efficiency problemsTime-consuming to solveSievingScreeningCrucibleSingle crystal

The invention discloses a large-thermal-field automatic loading device. The large-thermal-field automatic loading device at least comprises a feeding system, a discharging system and an electric control system, wherein the feeding system comprises a feeding table for containing a material basket and a material turning assembly used for turning the feeding table, and the discharging system comprises a collecting hopper and a discharging opening. The invention further discloses a large-thermal-field automatic loading method. The large-thermal-field automatic loading method comprises the following steps that the material basket is conveyed to the feeding table; the feeding table is lifted by a feeding lifting system; a silicon material is poured into the collecting hopper by the material turning assembly; and the silicon material entering the collecting hopper is screened by a vibration screening system and then is fed into a hopper or a crucible through the discharging opening. Accordingto the large-thermal-field automatic loading device and method, the problems of low efficiency and long time consumption of manual feeding in the existing single crystal preparation industry are solved, the silicon material is poured into the collecting hopper by the automatic feeding system, and then undergoes screening to be put into the hopper or the crucible through the discharging opening, the whole feeding process is realized by a machine, an operator is only responsible for operation after the silicon material is conveyed to the feeding table, so that the feeding efficiency is improved, and the enterprise cost and the risk of occupational diseases of workers are reduced.

Owner:NINGXIA LONGI SILICON MATERIALS

An automatic micro-dosing system

ActiveCN112317259BGuaranteed qualityReduce exposureLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention disclosed by the invention belongs to the technical field of photoelectric product production, and is specifically an automatic micro-filling system, including a base, a hose, a motor, a micro-disk, a filling needle, an inductor, a carrier and a fixing device, and the right side of the base There are extrusion grooves in the longitudinal direction, and hose grooves are provided on the left and right sides of the base. The hose grooves communicate with the extrusion grooves. The hose passes through the left hose groove and enters the right hose through the extrusion groove In the groove, the microdisk is located above the extrusion groove, and the middle part of the microdisk is equipped with a rotating shaft. The output shaft on the front of the motor is connected to the back end of the rotating shaft through a belt. Both are attached to the hose, the input interface of the filling needle is connected to the right side of the hose, and the output interface of the filling needle is located inside the carrier. The invention can effectively reduce the production cost, ensure the quality of the produced product, and reduce the It prevents the human body from contacting special materials and reduces the risk of occupational diseases.

Owner:苏州汇影光学技术有限公司

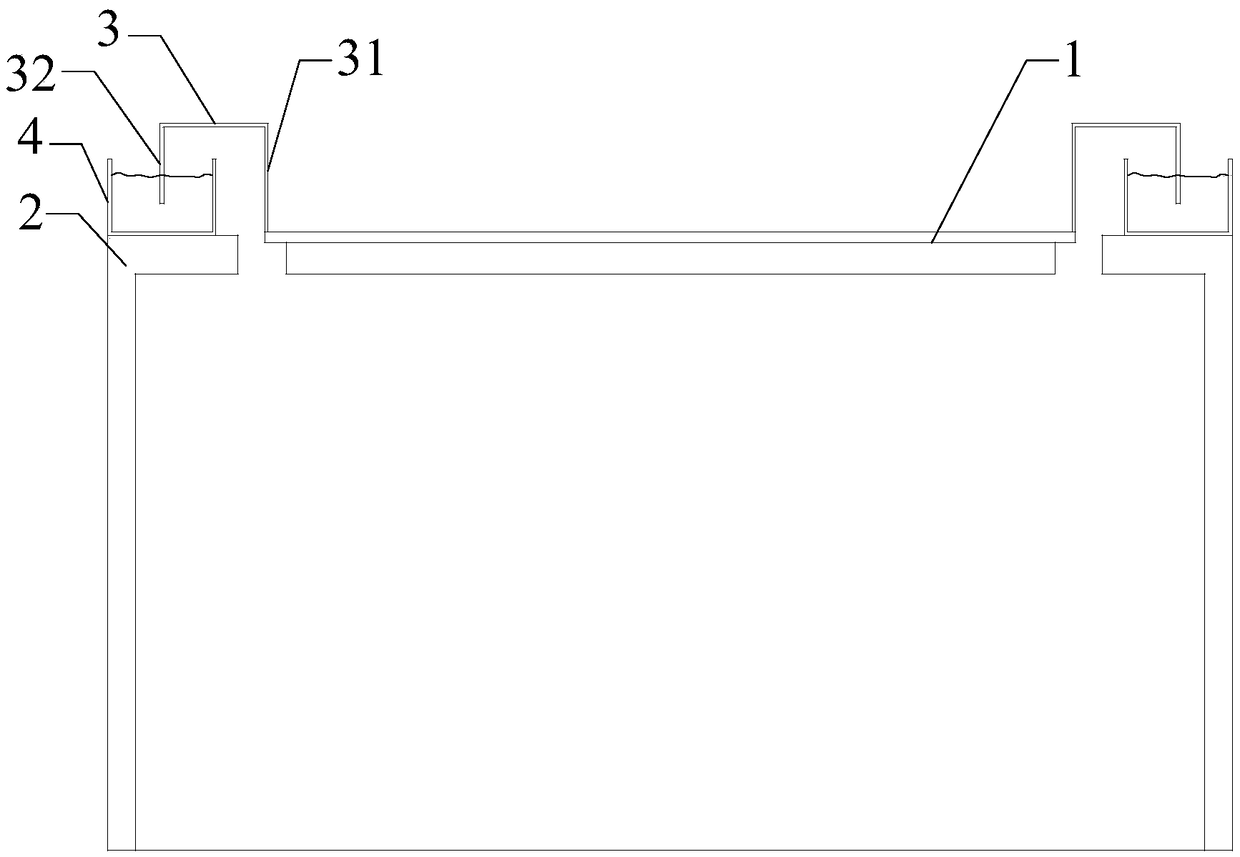

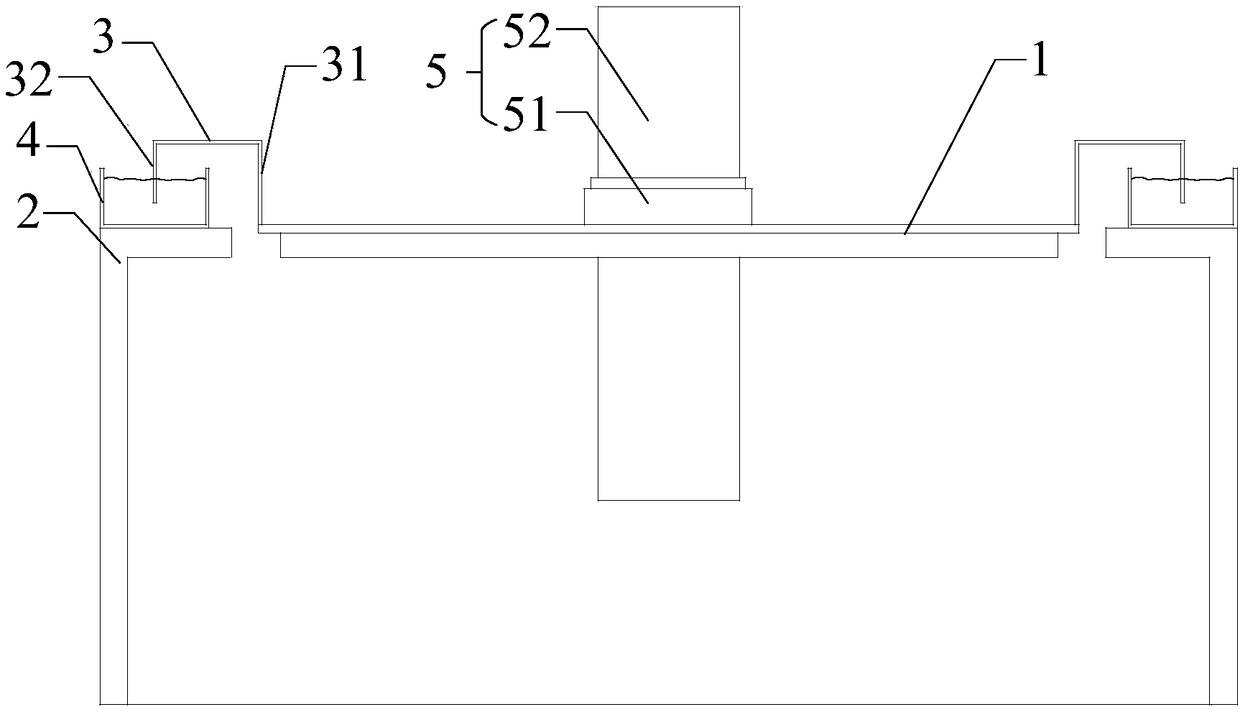

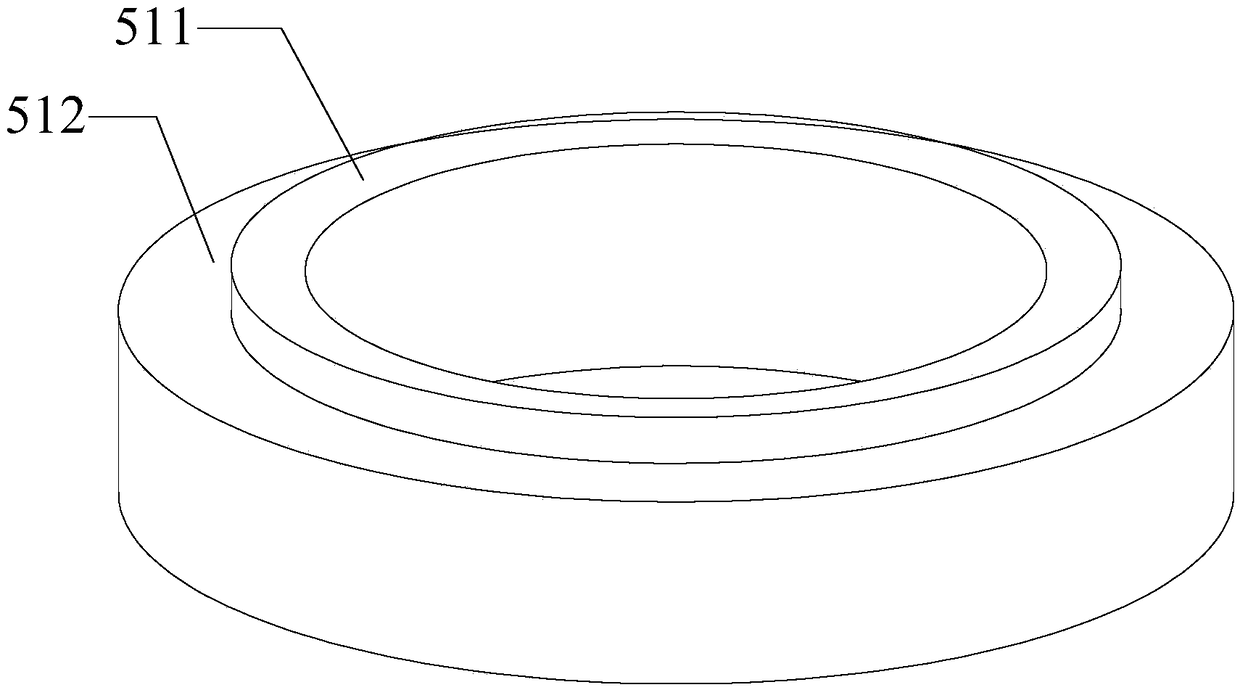

Novel submerged arc furnace and flue gas sealing device thereof

The invention relates to the field of metal smelting and discloses a novel submerged arc furnace and flue gas sealing device thereof. The flue gas sealing device comprises a rotary liner platform anda smoke hood. The rotary liner platform is arranged in a circular notch of the smoke hood. An upper half ring is arranged on the periphery of the rotary liner platform, and the upper half ring is connected with the rotary liner platform through ring-shaped groove plates of the inner ring of the upper half ring. A lower half ring is arranged on the top of the smoke hood in a circular manner. The upper half ring does not contact with the lower half ring, the ring-shaped groove plates of the outer ring of the upper half ring are arranged in a groove of the lower half ring, a smoke sealing mediumis arranged in the groove, a smoke sealing medium is arranged in the groove, and therefore the upper half ring and the lower half ring can form a mazy sealed structure. By means of the novel submergedarc furnace and the flue gas sealing device thereof, due to the flue gas sealing device, flue gas leakage of the submerged arc furnace can be effectively reduce, the environment is protected, meanwhile, the failure rate of the submerged arc furnace can be reduced by utilizing the flue gas sealing device, the occupational disease danger of workers is lowered, and the running rate of the submergedarc furnace is improved.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

Support mounting vehicle

PendingCN114017051AAvoid support workReduce the risk of occupational diseasesTunnelsProps/chocksEngineeringStructural engineering

The invention relates to the technical field of roadway support and discloses a support mounting vehicle. The vehicle comprises a first vehicle body, first supports, first sliding ways, first nut sliding blocks, first lead screws, first driving devices and a mounting arm, wherein the two first supports are arranged on the two sides of the first vehicle body in the width direction correspondingly; the first sliding ways are connected with the first supports and extend along the length direction of the first vehicle body; the first nut sliding blocks are arranged in the first sliding ways in a sliding mode; the first lead screws are rotatably arranged in the first sliding ways in the length direction of the first sliding ways, and the first lead screws are in threaded fit with the first nut sliding blocks; the first driving devices are arranged at one end of the first sliding ways and connected with the first lead screws, the first driving devices are used for driving the first lead screws to rotate and driving the first nut sliding blocks to slide along the first sliding ways; and the mounting arm is used for supporting the supporting shed frame in a roadway. According to the vehicle, automatic installation of the support shed frame can be realized, automation and unmanned operation during working face tunneling can be realized, and construction efficiency is improved.

Owner:CHINA COAL RES INST

Air-cooled pulverizer

PendingCN114768975AProtect heat sensitivityPrevent overflowVortex flow apparatusGrain treatmentsDust explosionEngineering

The invention provides an air-cooled pulverizer which comprises a coarse crushing mechanism, a fine crushing mechanism, a power mechanism and an air cooling mechanism, the coarse crushing mechanism comprises a hopper and a coarse crushing wheel, and a discharge port of the hopper is connected with a feed port of the coarse crushing wheel; the fine crushing mechanism comprises an integral cylindrical screen and a fine crushing tool bit, and a discharge port of the coarse crushing wheel is connected with a feed port of the integral cylindrical screen; the air cooling mechanism comprises a fan, a first pressure sensor, a second pressure sensor and a temperature sensor. By adopting the air-cooling series crushing design, the traditional Chinese medicinal materials are crushed in one step by utilizing the series crushing design of the coarse crushing mechanism and the fine crushing mechanism, and the crushing quality is stable; the crushing process is intelligently controlled through a pressure sensor and a temperature sensor, higher screen strength and screening effect are achieved through an integral cylindrical screen, dust-free crushing and dust overflow prevention are achieved through sealing and negative-pressure crushing, the risks of dust explosion and dust-related occupational diseases are reduced, and continuous crushing operation is achieved.

Owner:JIANGZHONG PHARMA

Environment-friendly all-dimensional grinding equipment capable of avoiding insufficient grinding

InactiveCN112621433AAvoid all-round sandingImprove work efficiencyEdge grinding machinesGrinding drivesDrive shaftReciprocating motion

The invention relates to the technical field of automobile accessories, and discloses environment-friendly all-dimensional grinding equipment capable of avoiding insufficient grinding. The environment-friendly all-dimensional grinding equipment comprises a shell, a screw rod is movably connected to the interior of the shell, and a sliding block is movably connected to the outer side of the screw rod. By means of the environment-friendly all-dimensional grinding equipment capable of avoiding insufficient grinding, through cooperative use of the lead screw and a driving shaft, a grinding wheel can reciprocate left and right in the grinding process, and a clamping plate can rotate, so that the all-dimensional grinding effect is achieved, and the grinding effect and the working efficiency of workers are greatly improved; a pressing plate can adjust the position of the grinding wheel according to accessories of different sizes, so that the step of manual adjustment is omitted, and automation is enhanced; and through cooperative use of an air extractor and an air outlet, in the grinding process, the air extractor at a short distance can collect and treat dust generated in the grinding process, dust flying is avoided, the safety of the working environment of workers is guaranteed, and the risk of occupational diseases is reduced.

Owner:义乌二王电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com