Airtight dust-proof granulation, drying and granule arranging integrated pharmaceutical device

A pharmaceutical equipment and dust-free technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of high labor intensity, affecting normal production, and difficulty in automatic production, so as to improve the effect of whole grains, Reduce the labor intensity of workers and the effect of cleaning the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

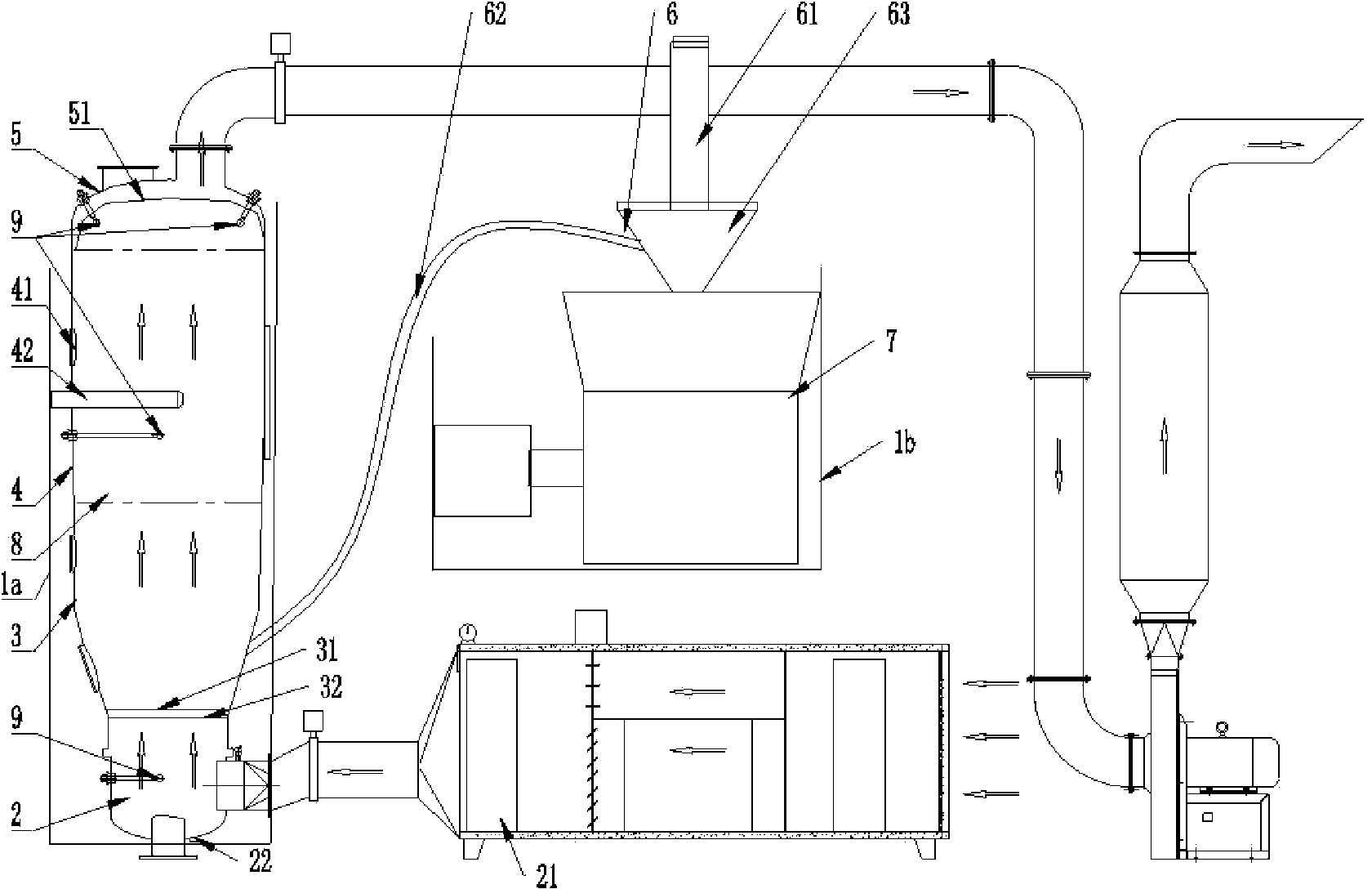

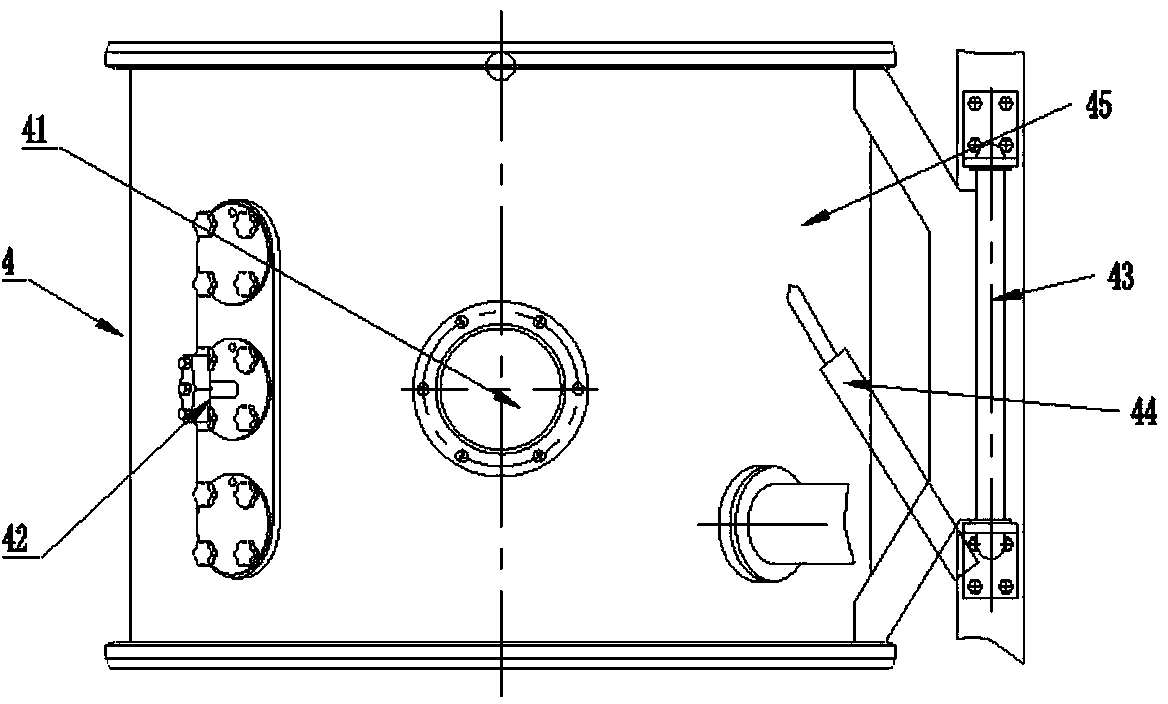

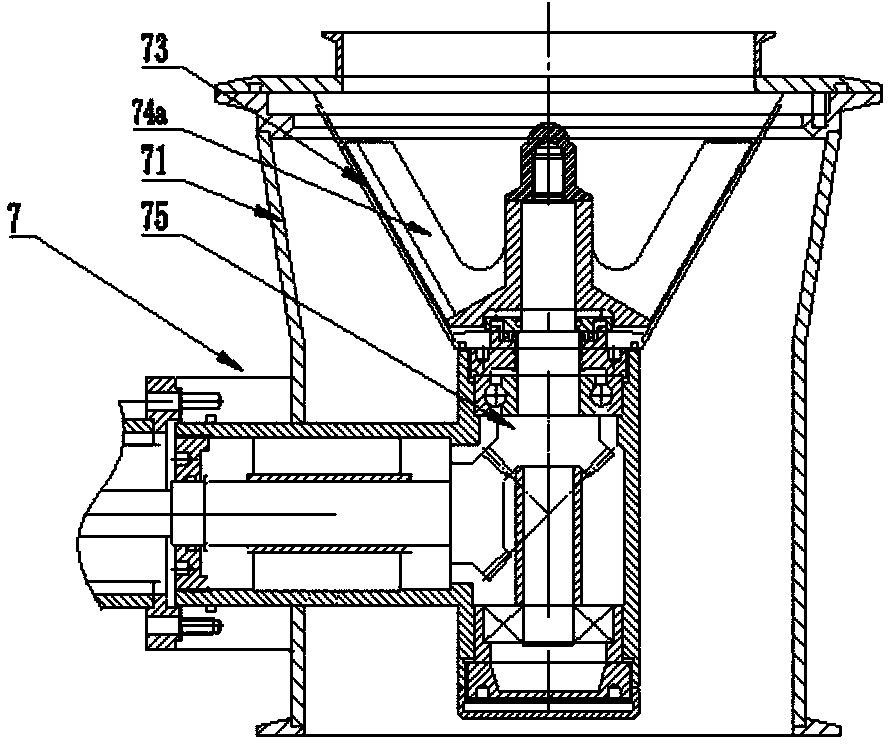

[0017] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings. Such as Figure 1-Figure 3 As shown, the airtight and dust-free granulation, drying, and granulation integrated pharmaceutical equipment of this embodiment includes frame bodies 1a and 1b, air inlet system 2, granulation barrel part 3, intermediate barrel part 4, and exhaust and dust removal system 5. Conveying material system 6 and granulation system 7, etc., corresponding to the integrated pharmaceutical equipment of airtight and dust-free granulation, drying, and granulation, there is a corresponding intelligent control system, air intake system 2, granulation barrel part 3, middle The barrel part 4 and the exhaust and dust removal system 5 are sequentially arranged on the same frame body 1a from bottom to top. Connect with each other to form a tower-type integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com