A fully enclosed coal conveying system for a thermal power plant

A technology for thermal power plants and coal conveying systems, which is applied in transportation, packaging, loading/unloading, etc., and can solve the problems of direct impact position wear of coal, dust affecting the on-site working environment, and powder spraying of tail guide grooves, etc. Risk of safety accidents, improvement of coal transportation operation environment, and effect of reducing dredging times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

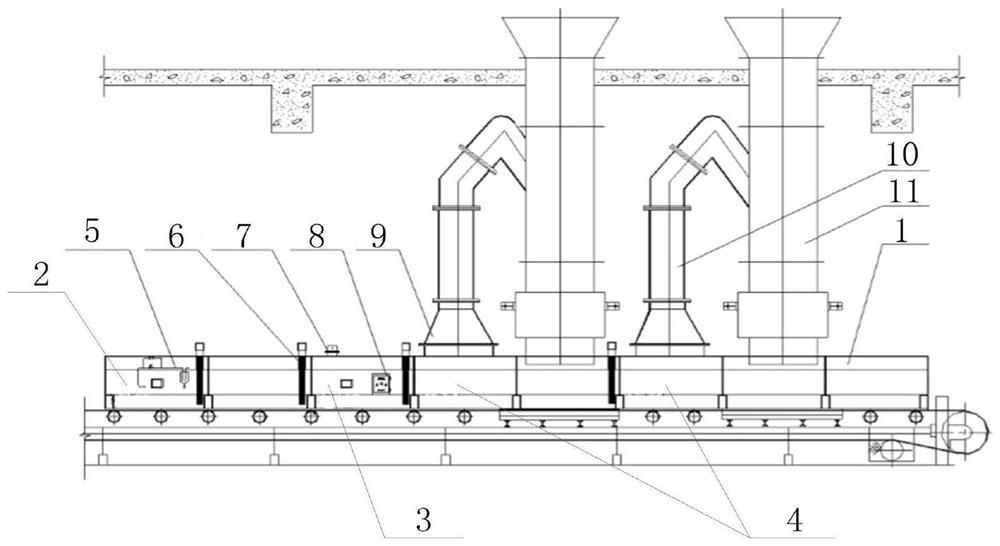

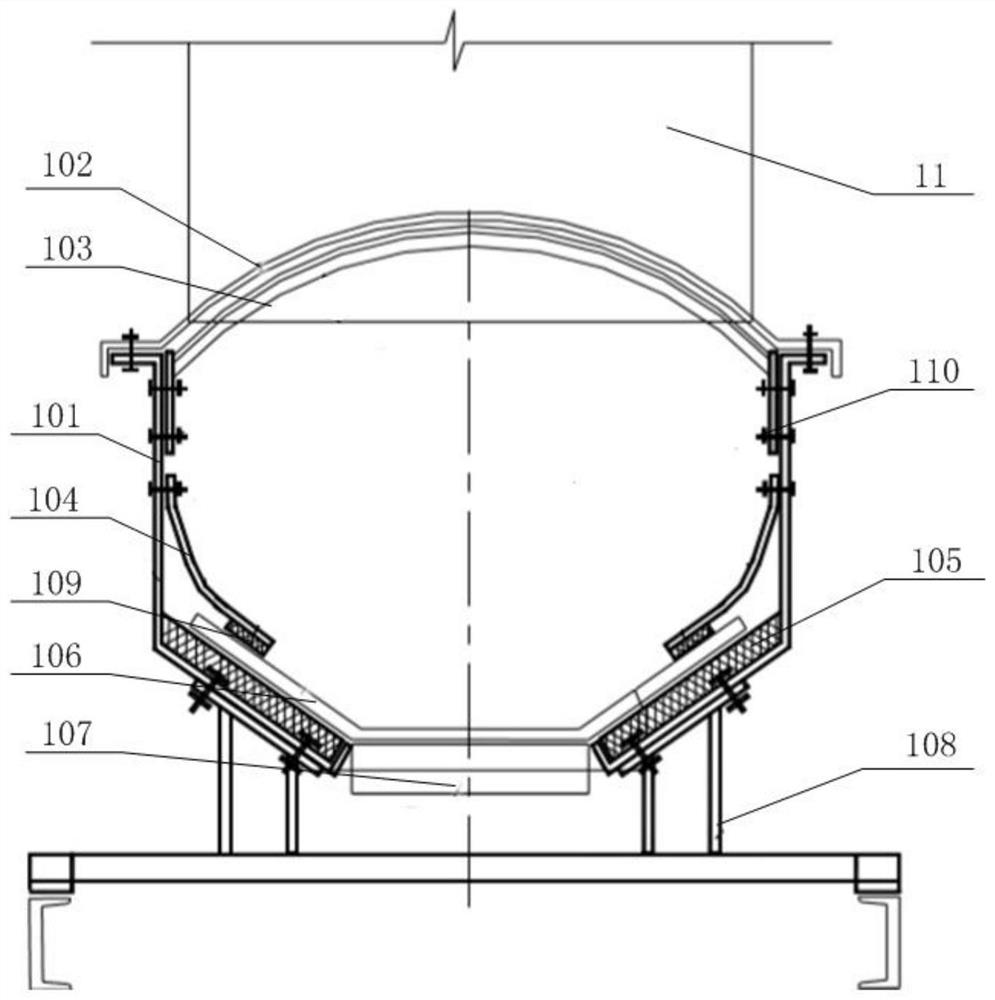

[0025] Such as Figure 1-3 As shown, a fully enclosed coal conveying system for a thermal power plant includes a material guide trough 1, a return pipe 10, and a blanking tube 11. The pipe 11 communicates with the inside of the material guide tank 1, the inside of the material guide tank 1 is provided with a buffer zone 4, an inspection area 3, and a purification area 2, and the intersection of the buffer area 4, inspection area 3, and purification area 2 is provided with a stop Dust device 6, a return pipe 10 is provided directly above the buffer zone 4, and a current collector 9 is provided at the bottom of the return pipe 10, and the current collector 9 is installed on the top of the buffer zone 4, and the inspection area 3 A detection device 7 and a control box 8 are arranged inside, and a spray system 5 is arranged inside the purification area.

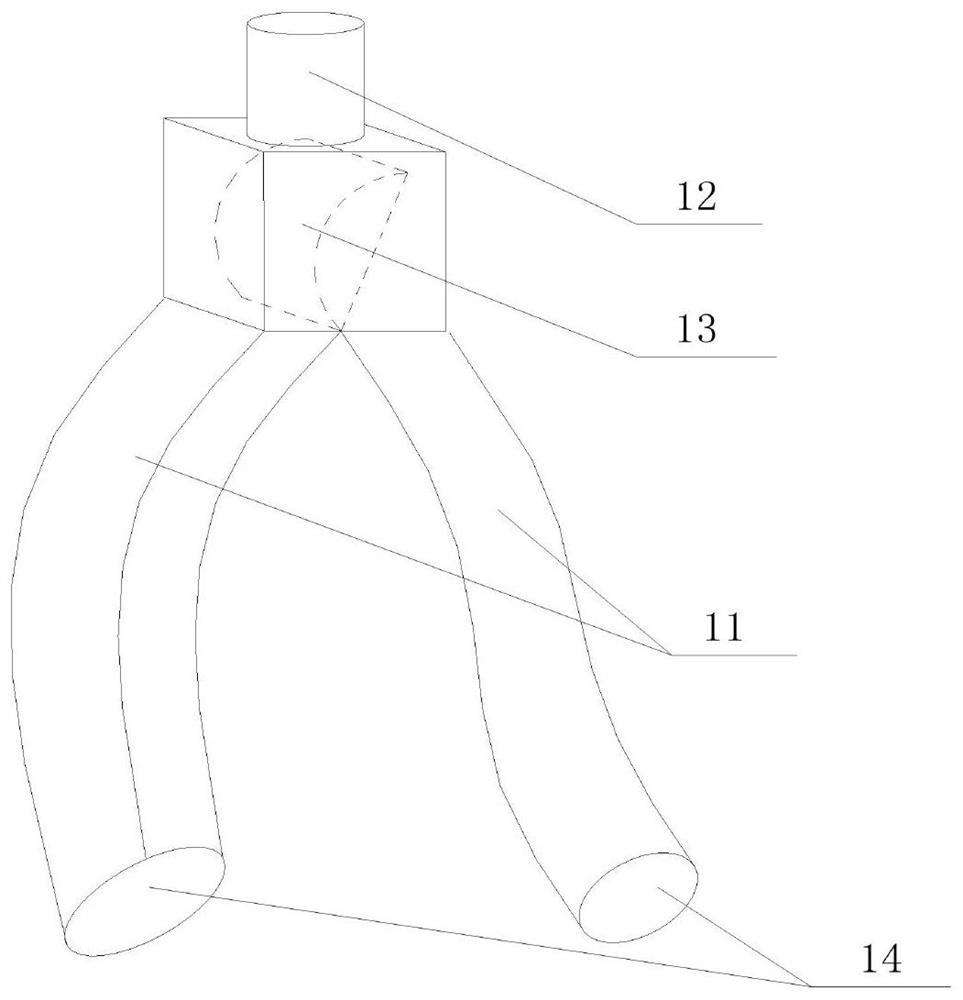

[0026] Specifically, the discharge pipe 11 includes a discharge port 12, a boat-type tee flap 13, and a discharge port 14. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com