Runner preheating cover and runner preheating method

A launder and convection trough technology, applied in the field of launder preheating cover and launder preheating, can solve the problems of long heating time and large energy loss, and achieve the goals of reducing waste, saving resources and costs, and shortening preheating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

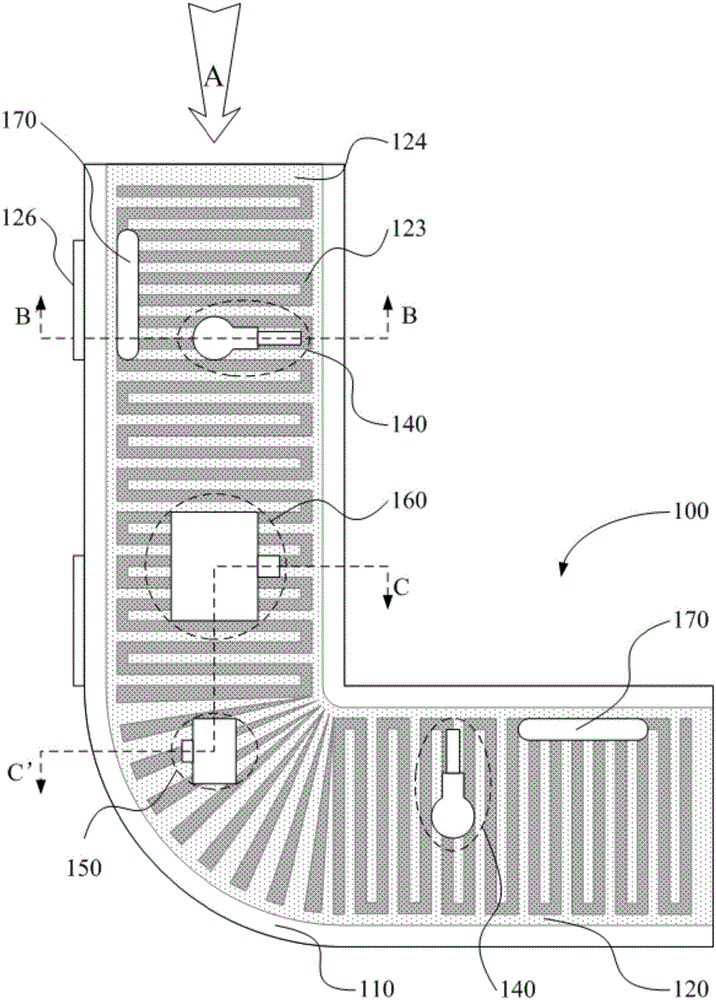

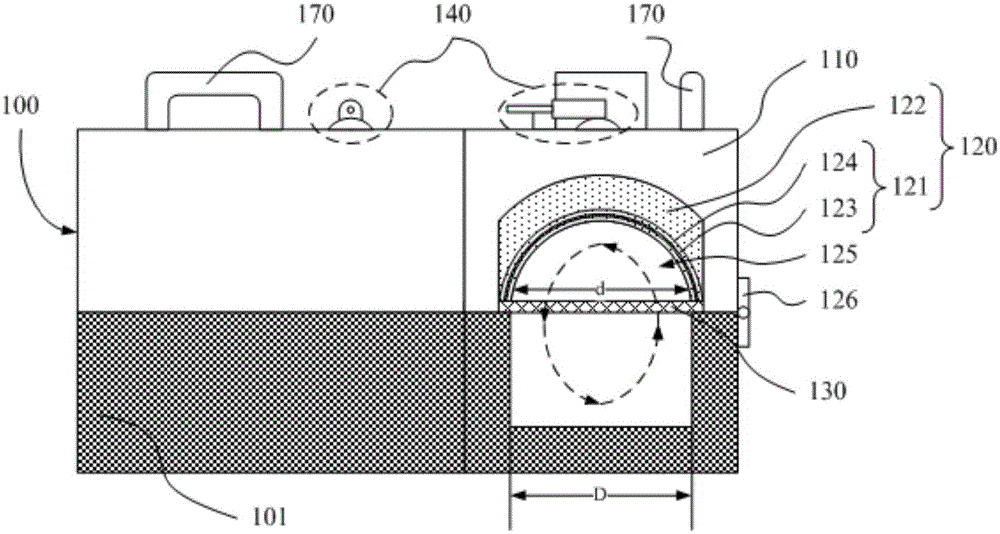

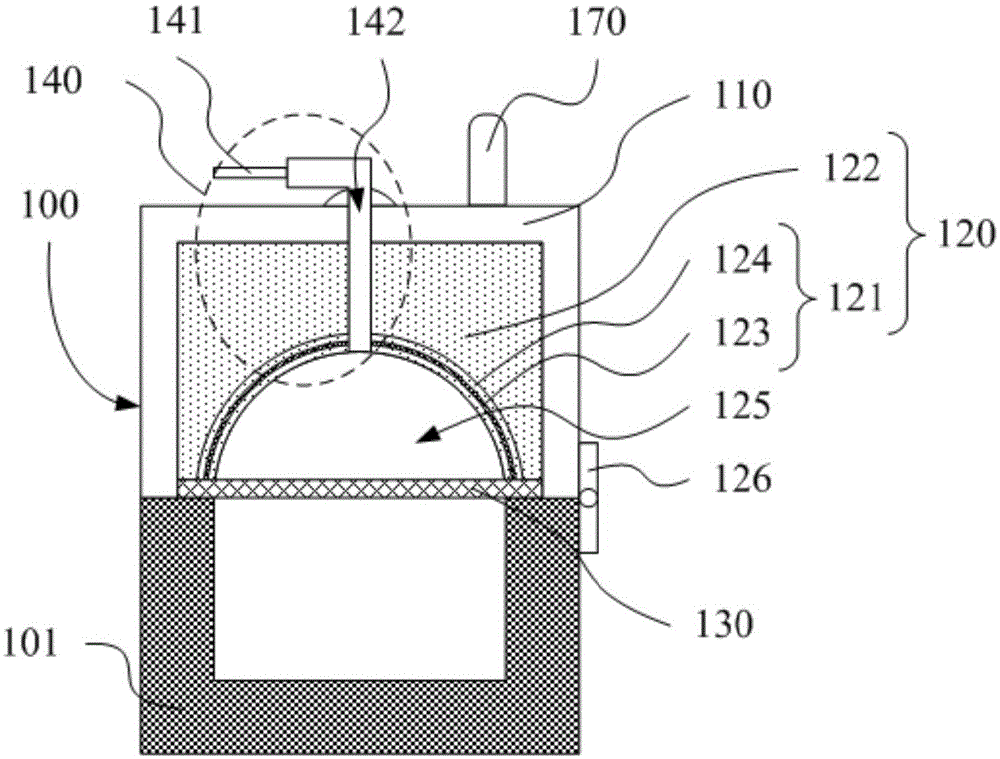

[0048] It can be seen from the background art that the method of preheating the launder in the prior art has the problems of too long heating time and too large energy loss. Combining with the existing technology to preheat the launder, we will analyze the reasons for the excessively long heating time:

[0049] In the prior art, silicic acid wool is usually used to cover the launder, and then the natural gas is directly heated with a musket. However, if the silicic acid cotton cover is too tight, the musket will be easily extinguished; if the cover is not tight and the opening is too large, the heat dissipation will be too fast, and the heat loss will increase the preheating time, consume more natural gas, waste resources and increase costs.

[0050] In addition, using silicic acid cotton to cover the launder will easily generate impurities during winding, which will cause inclusions in the ingot during the casting process, affecting the composition of the ingot and the qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com