Large-thermal-field automatic loading device and method

A technology of automatic charging and large thermal field, applied in chemical instruments and methods, transportation and packaging, solid separation, etc., can solve problems such as low efficiency and long time consumption, improve charging efficiency, reduce enterprise costs and employees suffer from occupational diseases. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

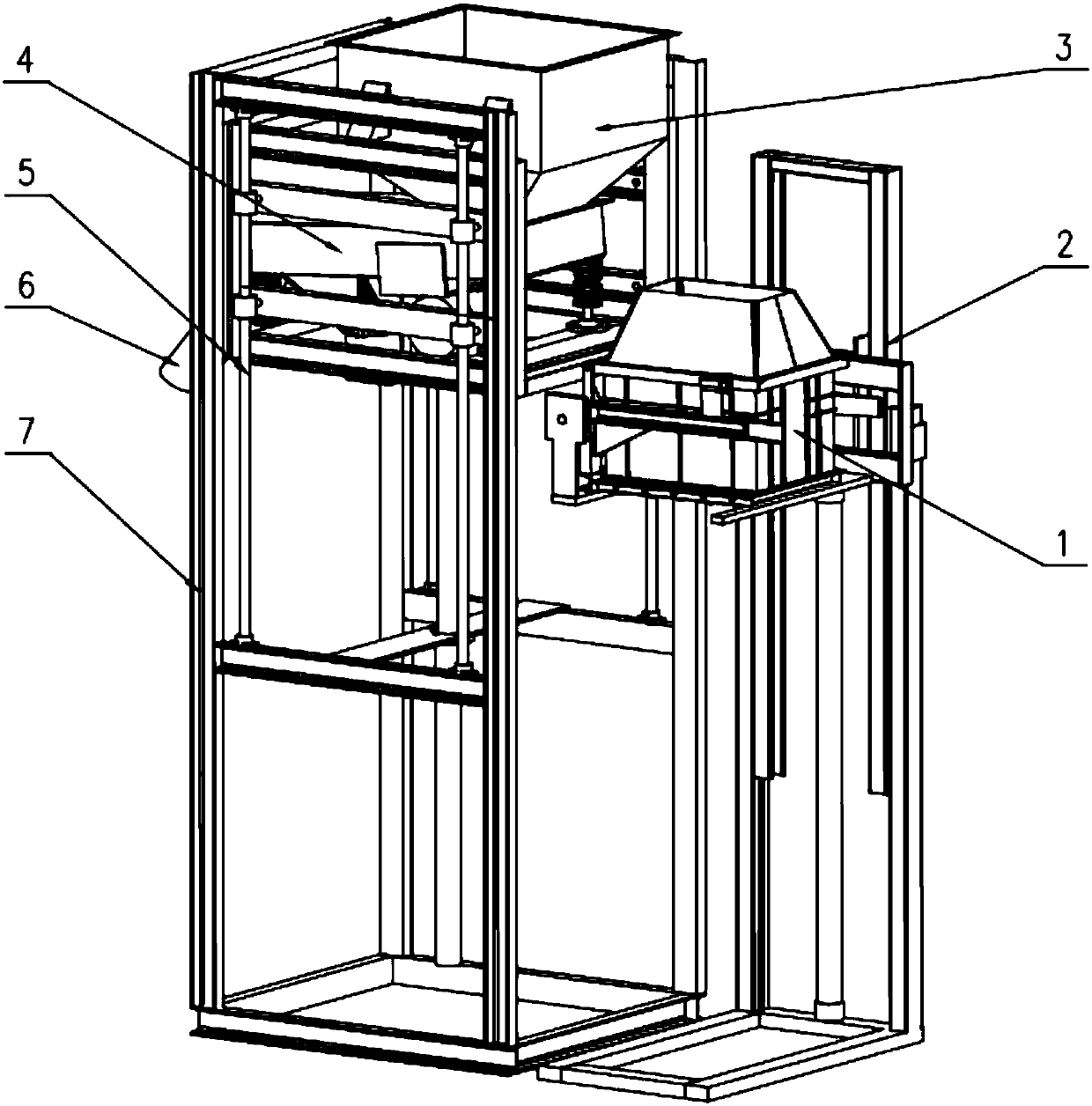

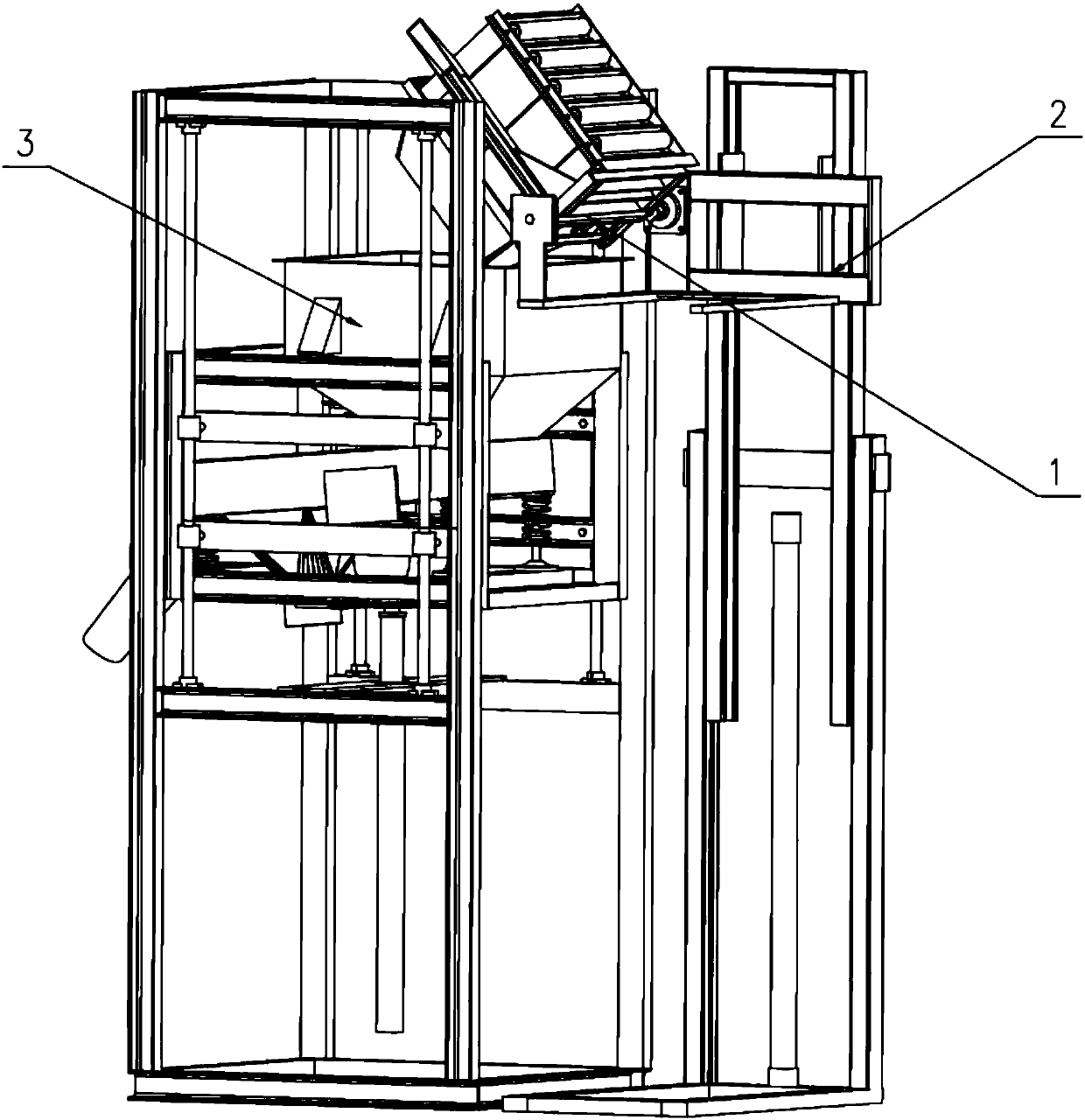

[0024] The structure of a large thermal field automatic charging device provided by the invention is as follows: figure 1 As shown, it includes at least a loading system 1, a blanking system, and an electronic control system (not shown) that controls the work of the loading system 1 and the blanking system. The loading system 1 includes at least a loading platform for placing material baskets and for The turning assembly for turning over the loading table and the material basket, and the unloading system at least includes a collecting hopper 3 and an unloading port 6 for sending silicon material into the hopper or crucible. In order to facilitate the movement of the material basket on the loading platform, the bottom surface of the loading platform is set as a bottom platform formed by connecting rotating shafts, and the movement of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com