Automatic paint spraying assembly line for plastic parts

An automatic painting and assembly line technology, applied in painting booths, spraying devices, etc., can solve problems such as susceptibility, human hazards, and difficulty in ensuring the quality of plastic parts painting, so as to save time, improve work efficiency, and reduce occupational diseases. risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

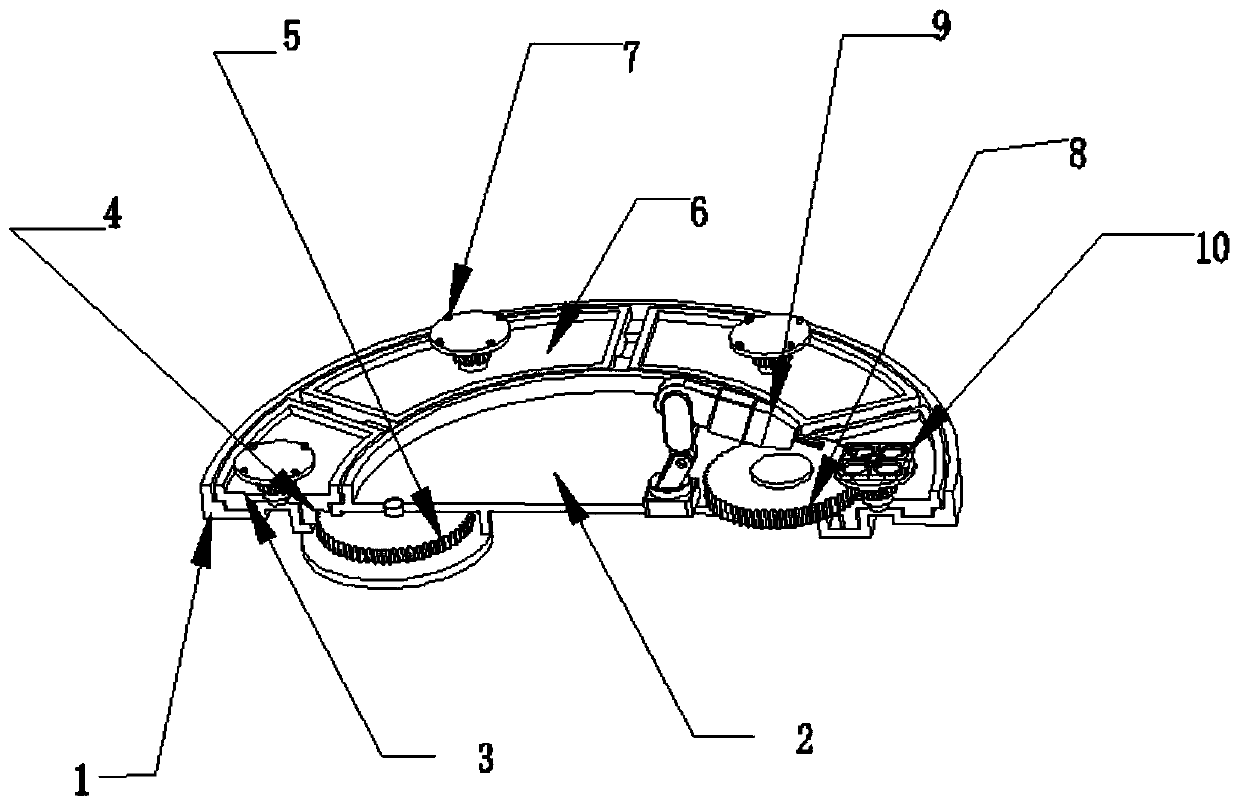

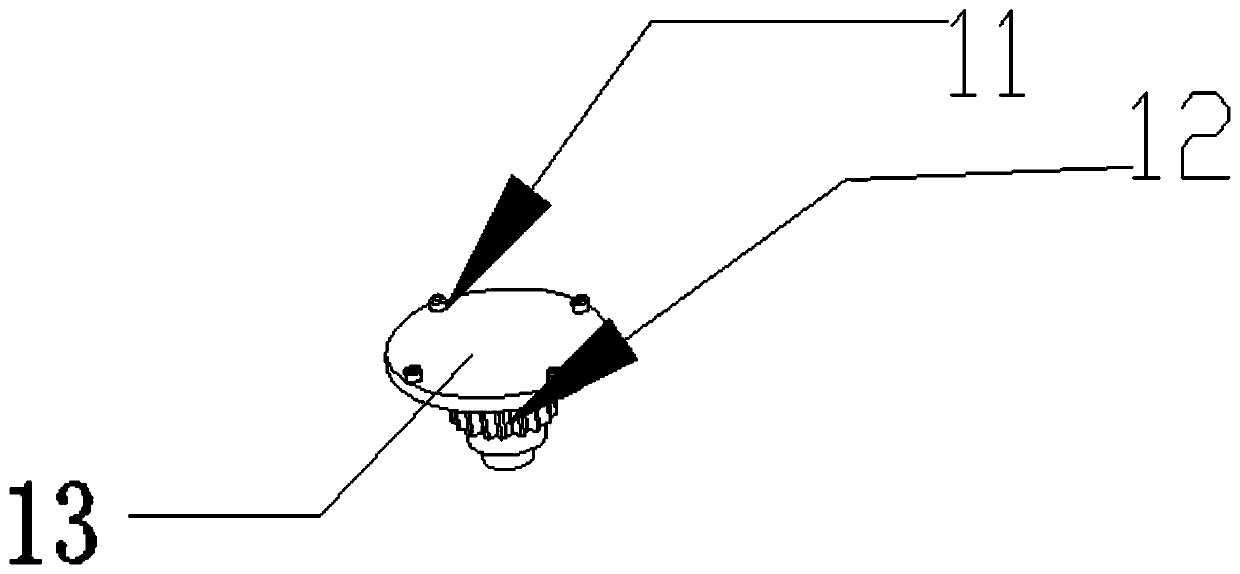

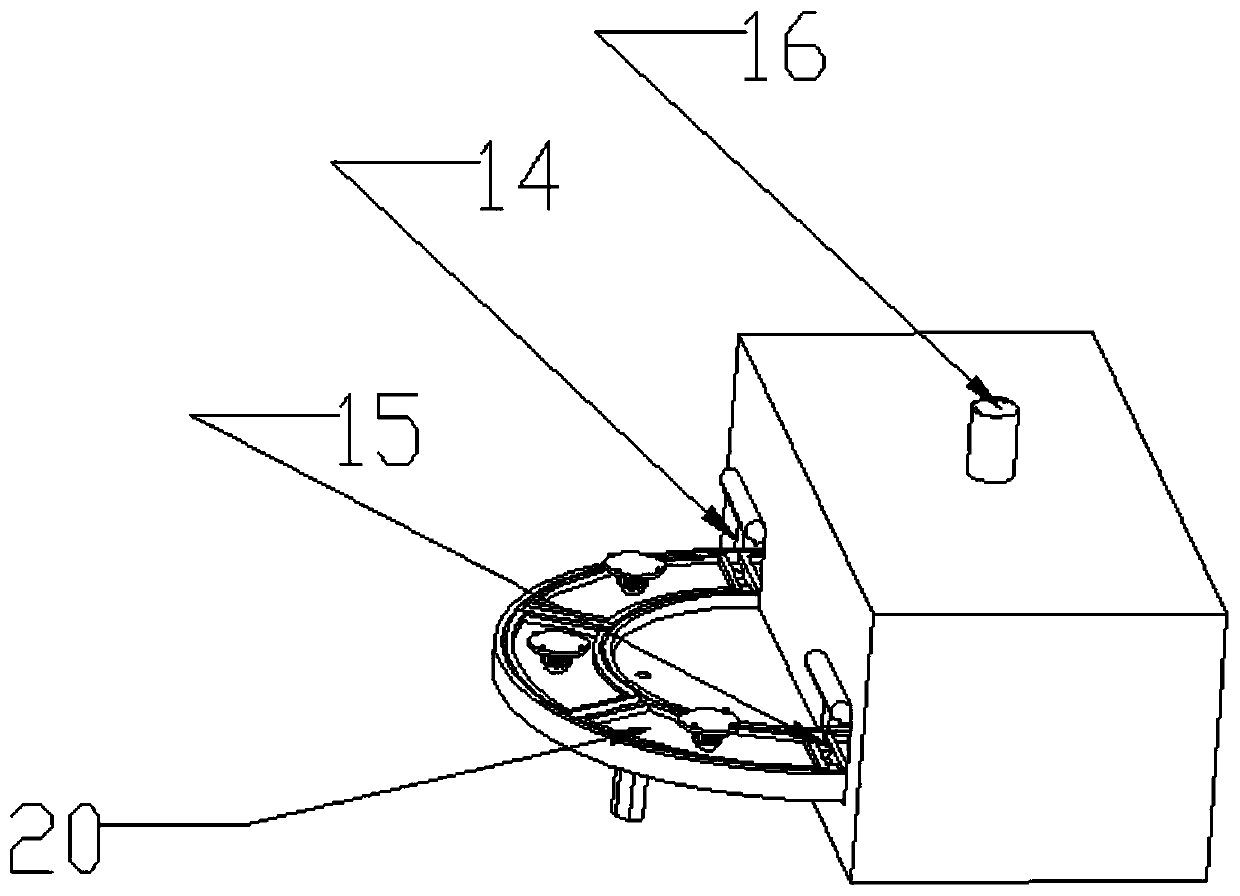

[0035] Embodiment 1: as Figure 1-Figure 3 As shown, a turntable for an automatic painting station includes a turntable installation frame and a turntable installed in the turntable installation frame 1. The turntable installation frame 1 includes a circular tray with a vertical side wall and a support frame; The fixed disk 2 and the rotating disk 3 with straight side walls, the fixed disk 2 is concentrically fixed on the upper surface of the circular tray, the vertical side wall of the fixed disk 2 and the vertical side wall of the circular tray form a slide rail, and the rotating disk 3 is installed on the Inside the slide rail; 6 stations 6 are uniformly arranged on the rotating disk 3, and each station 6 is respectively provided with a workpiece clamping tool 7; the bottom surface of the rotating disk 3 is provided with an internal gear 4, and the bottom surface of the fixed disk 2 is connected with a circular tray. A power gear 5 meshing with the internal gear 4 is arrang...

Embodiment 2

[0047] Embodiment 2: The closed paint spray booth can also be used in conjunction with the commonly used linear workbench by changing the positions of the inlet and outlet. The feed inlet and outlet of the closed paint spray booth are respectively set in On the opposite side wall of the main body, the linear workbench passes through the material inlet and outlet, runs through the main body, advances according to the rhythm, and turns around. In the middle painting station, a painting robot is set up for automatic painting, and the robot performs automatic painting. The principle and procedure are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com