Support dismounting vehicle

A technology for dismantling vehicles and vehicle bodies, which is applied in pillars/brackets, mining equipment, earthwork drilling and mining, etc. It can solve the problems of restricted automation, unmanned, difficult automation of anchor protection work, and lack of large-scale popularization, etc. Humanization, reducing the risk of occupational diseases, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

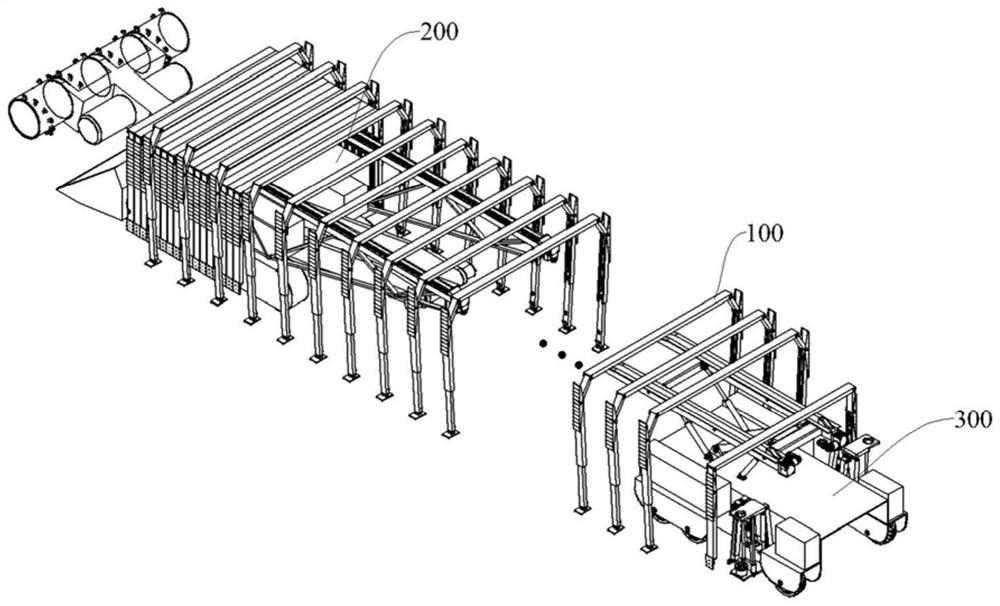

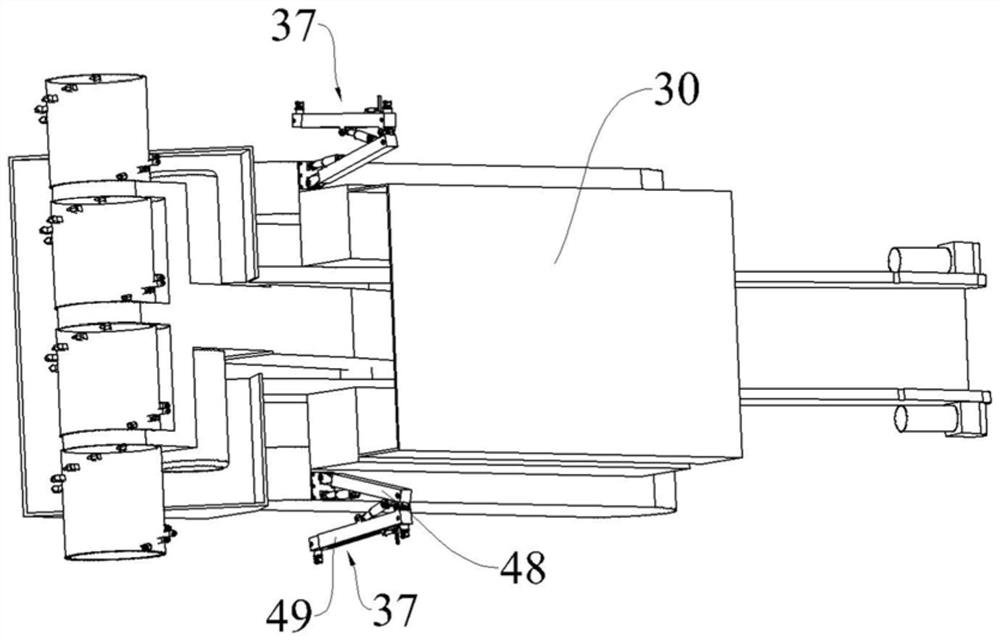

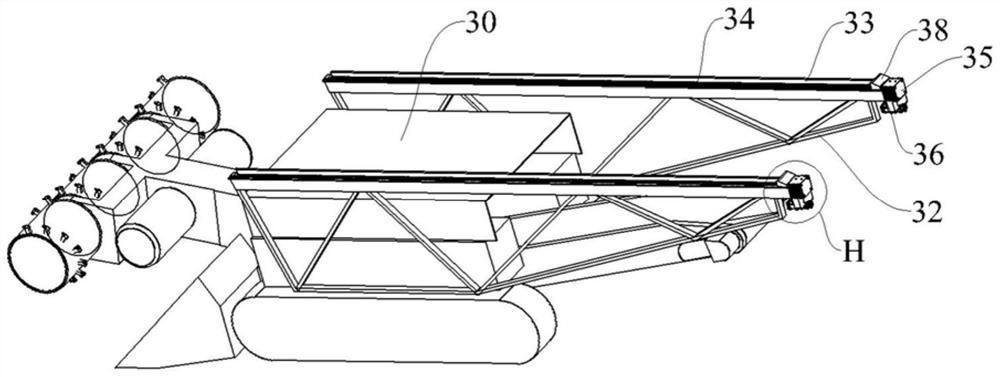

[0050] see Figure 1 to Figure 32 As shown, this embodiment provides a roadway support device, including a support scaffold 100 , a support installation vehicle 200 and a support removal vehicle 300 . The support scaffold 100 is detachably supported in the roadway; the support installation vehicle 200 includes a first vehicle body 30 (which may be a boring machine) and an installation assembly installed on the first vehicle body 30, the The installation assembly is used to support the support scaffold in the roadway; the support dismantling vehicle 300 includes a second car body 31 and a disassembly assembly installed on the second car body 31, and the disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com