An automatic micro-dosing system

A filling system and micro-amount technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of volatile special elements, easy to affect people, difficult to control the dosage, etc., to avoid displacement, reduce Human contact with special materials, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

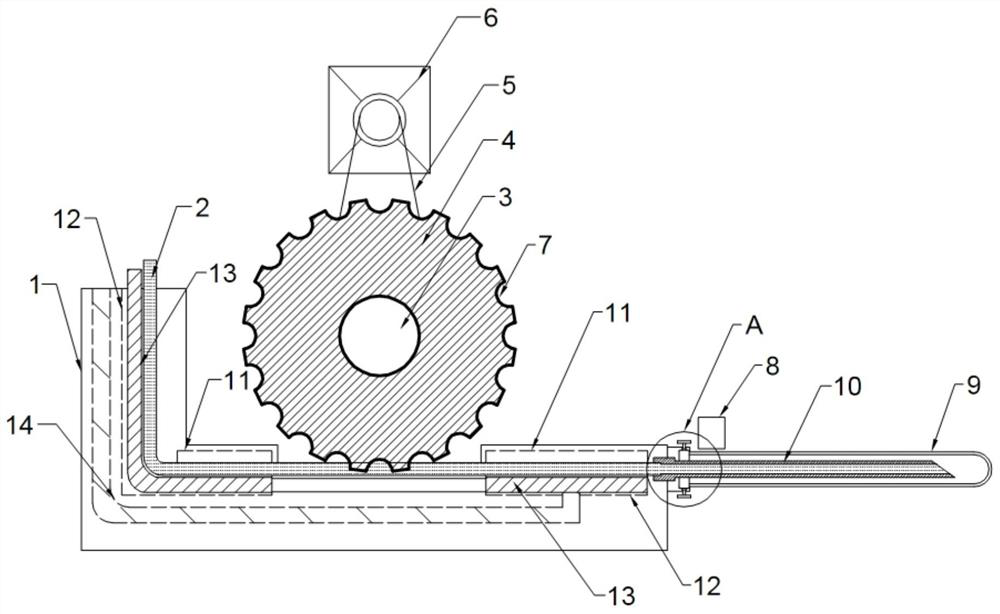

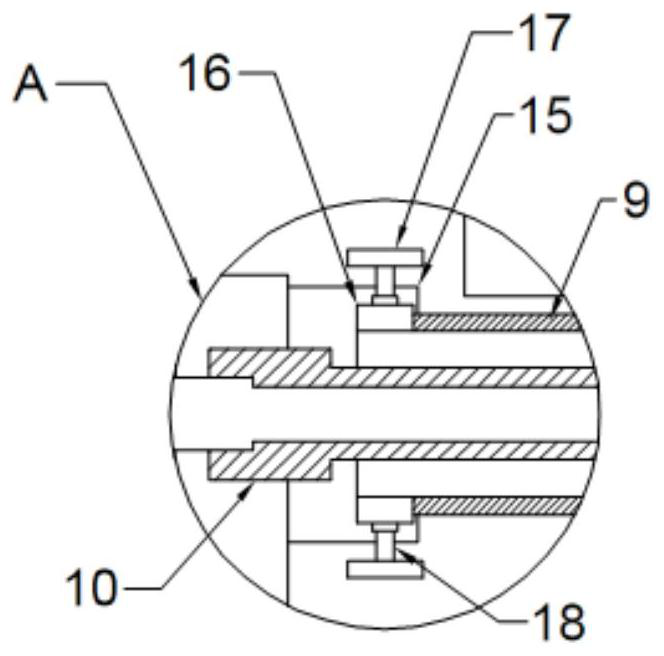

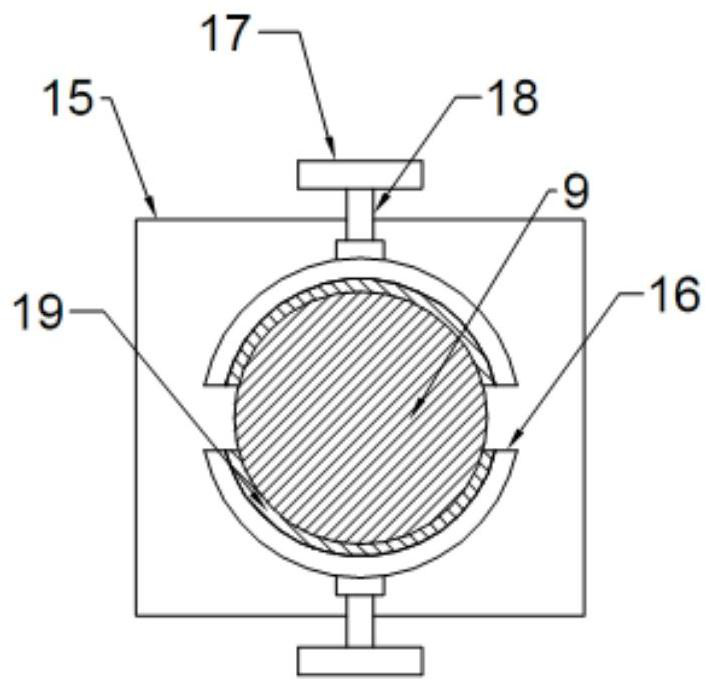

[0019] see Figure 1-3 , the present invention provides a technical solution: an automatic micro-filling system, including a base 1, a hose 2, a motor 6, a micro-disk 4, a filling needle 10, an inductor 8, a carrier 9 and a fixing device 15, The right side of the base 1 is longitudinally provided with an extrusion groove, and the left and right sides of the base 1 are provided with hose grooves, the hose groove communicates with the extrusion groove, and the hose 2 passes through The hose groove on the left side enters the hose groove on the right side through the extrusion groove, the microdisk 4 is located above the extrusion groove, the middle part of the microdisk 4 is equipped with a rotating shaft 3, and the front output shaft of the motor 6 passes through the belt 5 is connected to the back end of the rotating shaft 3, and the outer wall of the micro-disc 4 is uniformly provided with a plurality of micro-grooves 7, and the outer wall of the micro-disk 4 and the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com