Molten-loss type brazing auxiliary positioning for oil cooler

An oil cooler and auxiliary positioning technology, which is applied in the direction of welding/cutting auxiliary equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of secondary displacement of parts, installation size dislocation, displacement, etc., to ensure the product installation position , positioning reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

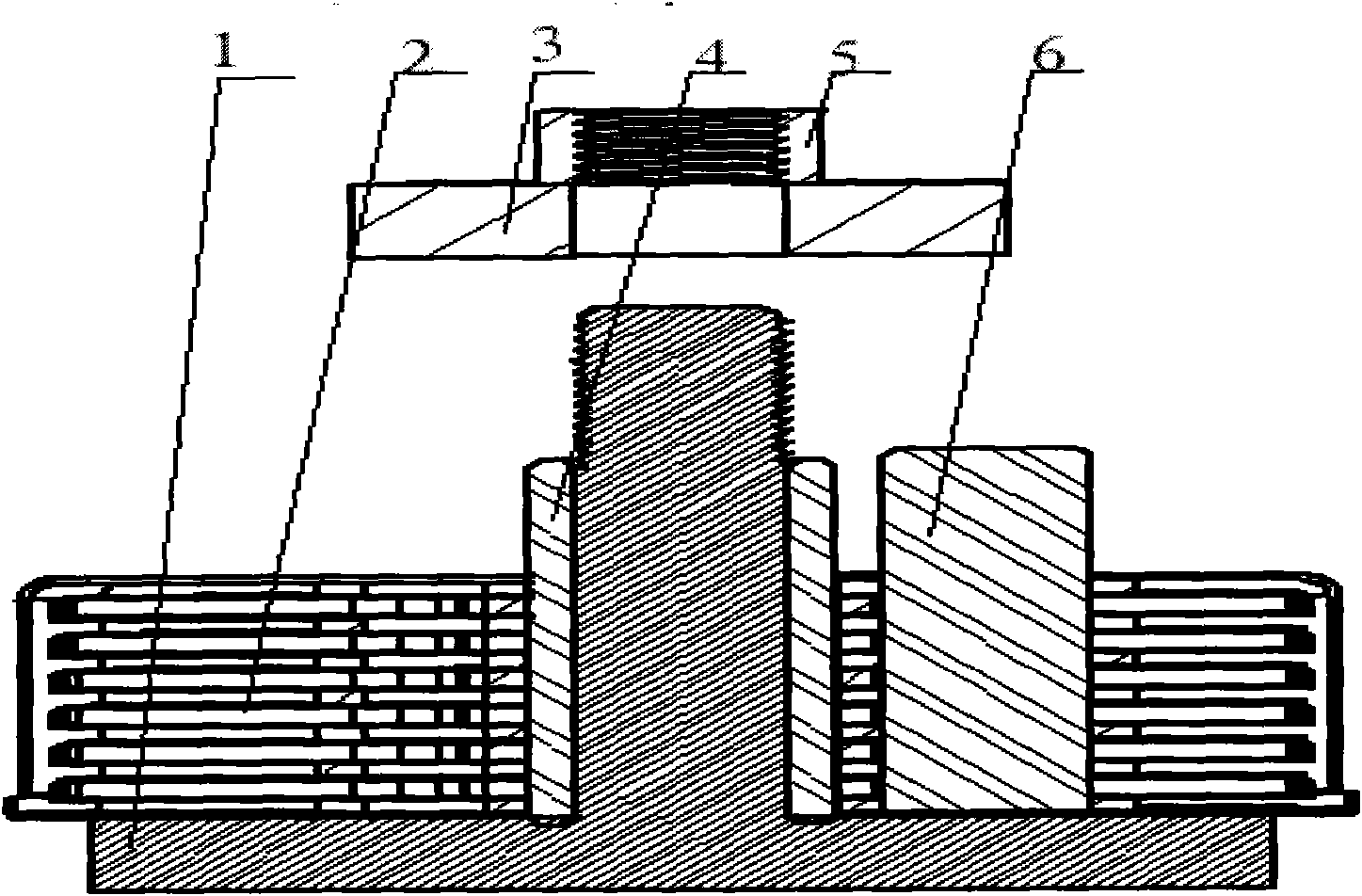

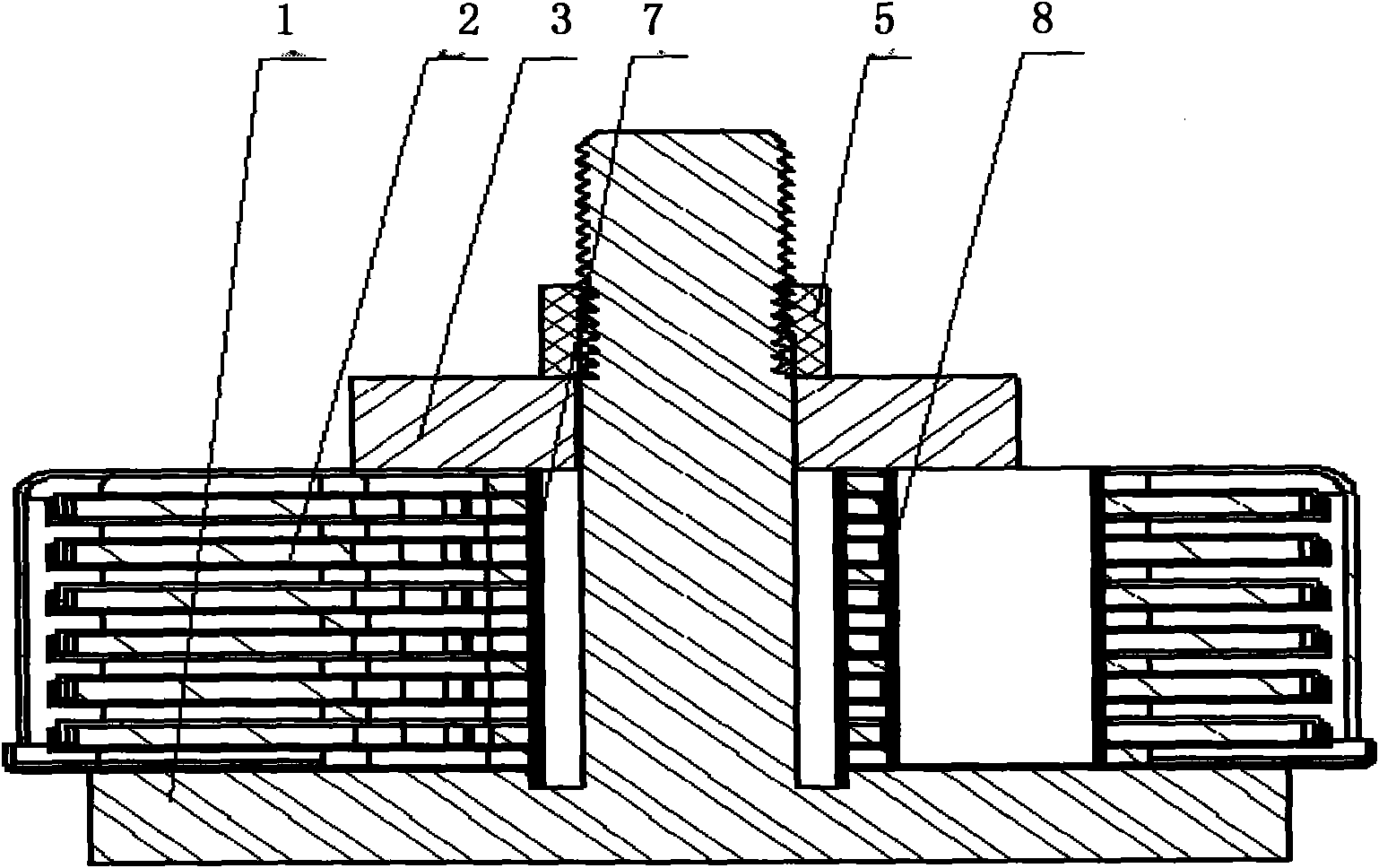

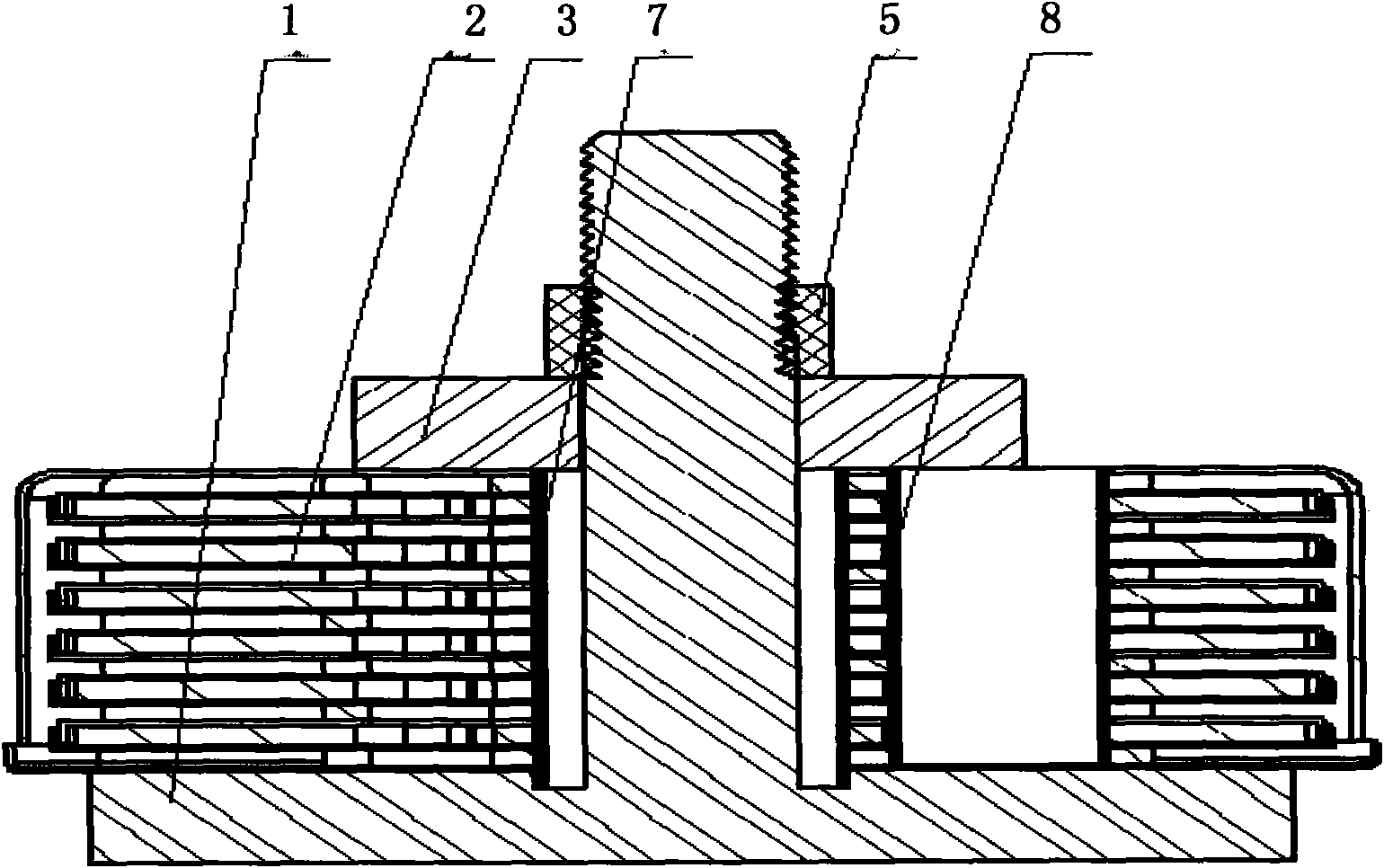

[0010] like figure 2 Shown: a melt-loss type brazing auxiliary positioning of an oil cooler, including a clamp body 1, an oil cooler 2, an upper clamp body 3, a center positioning 7, a nut 5 and a round hole positioning 8, and the oil cooler 2 is placed On the clamp body 1 and positioned on the clamp body 1 through the center positioning 7 and the round hole positioning 8 , the upper clamp body 3 is pressed on the oil cooler 2 through the nut 5 .

[0011] The material of the center positioning 7 and the circular hole positioning 8 is T2 copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com