Sander

一种砂光机、联接件的技术,应用在砂光机领域,能够解决不能解决弊端等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

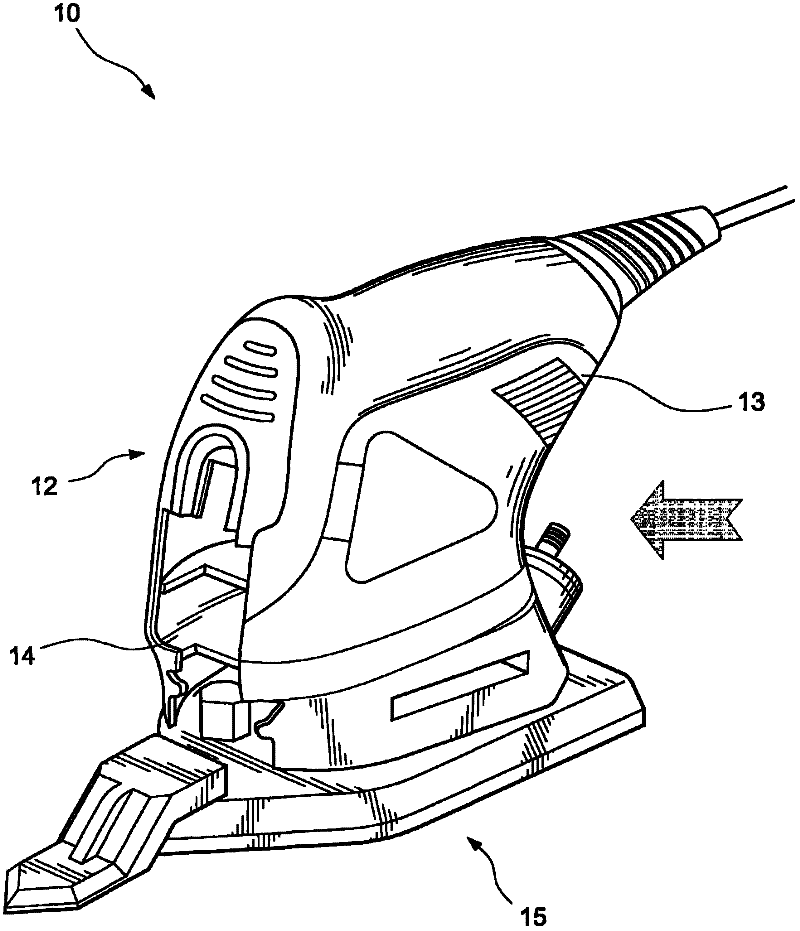

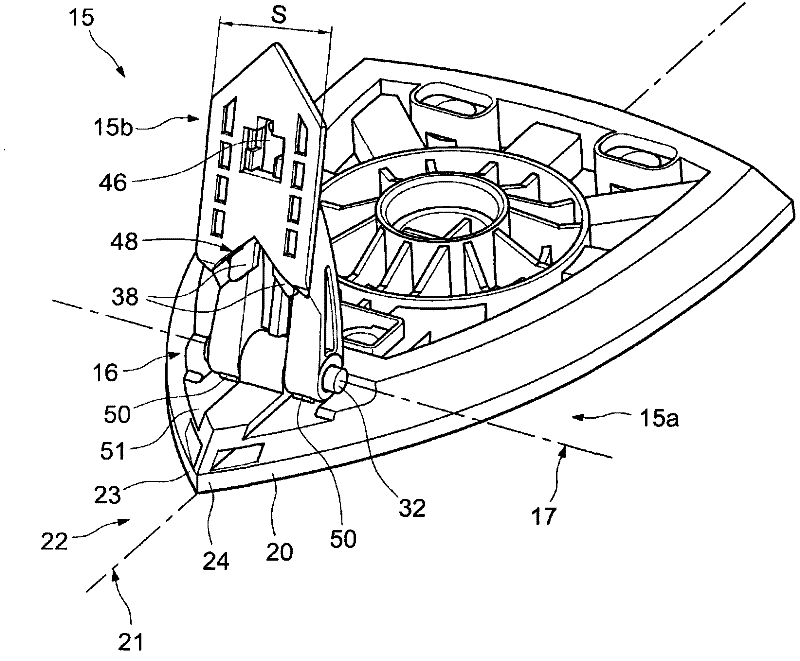

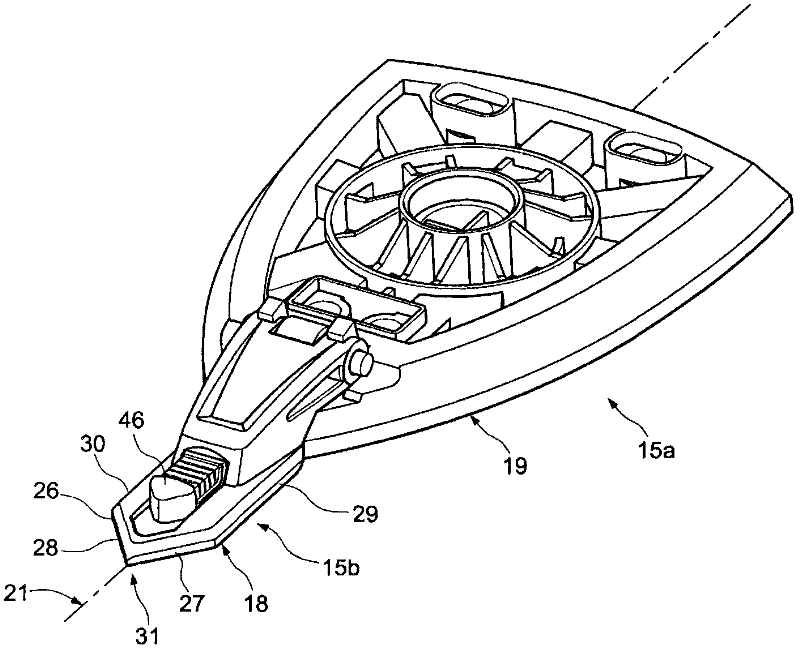

[0034] exist Figure 1 to Figure 5 The sander 10 shown in detail of the first embodiment of the invention is used for sanding inside corners and other hard-to-reach places. The sander 10 has a main body 12 including a grip portion 13 by which the main body 12 can be held by a user. At the front of the main body 12 a recess 14 is provided. The main body 12 houses a motor (not shown) and a vibration drive mechanism (not shown). A base member 15 provided below the main body 12 is fixed to the vibration driving mechanism so as to support a working member (not shown). The working member may be a sheet of sandpaper (not shown) or similar abrasive removably attached to the lower plane of the first base member 15, such as by hook and loop fasteners or adhesive.

[0035] The base member 15 includes a first portion 15a directly connected to the vibration drive mechanism and a second portion 15b connected to the first portion 15a by a coupling 16 such that the first base member 15a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com