Coupling structure of ink jet printing ink box

A connection structure, inkjet printing technology, applied in printing and other directions, can solve the problems of difficult application of inkjet printers, occupying height, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

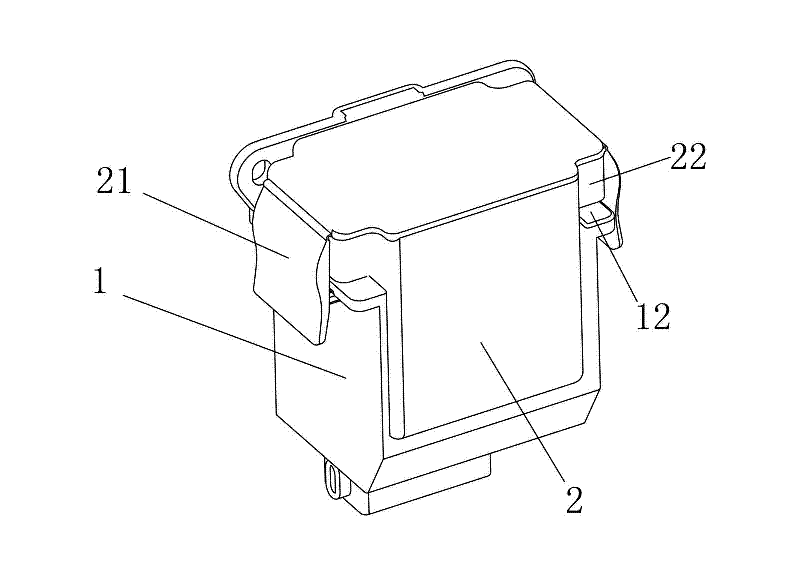

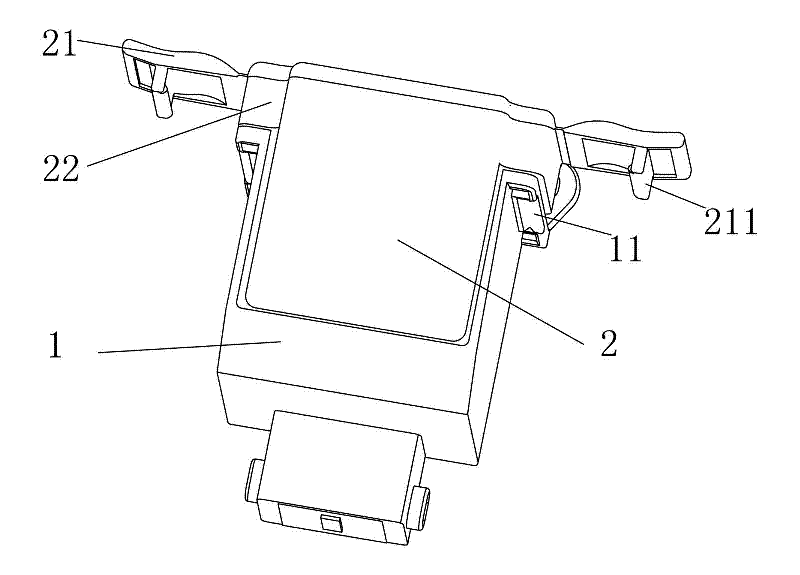

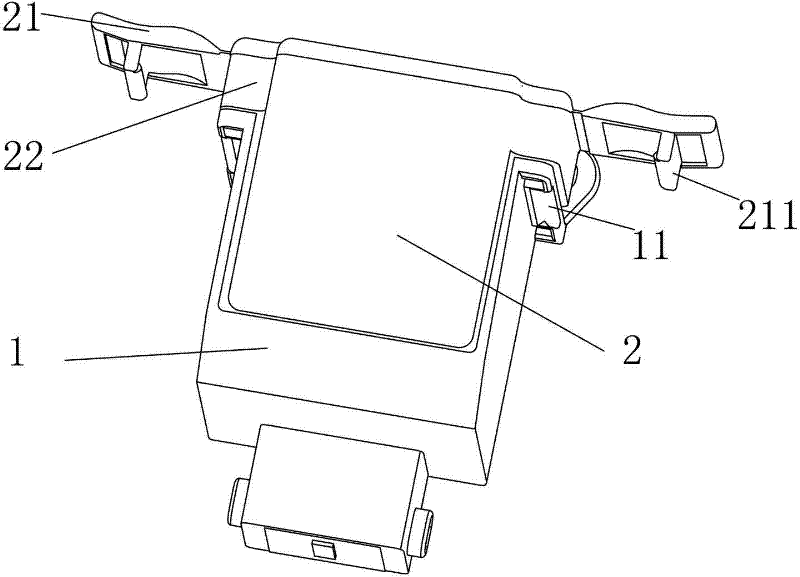

[0012] refer to Figure 1~Figure 2 , a connection structure for an inkjet printing ink cartridge, which includes an ink cartridge installation case 1, an ink cartridge 2 is installed in the ink cartridge installation case 1, and lugs 21 extend on both sides of the top of the ink cartridge 2, and the lugs 21 and the ink cartridge 2 The top is integrally formed, and the two sides of the ink cartridge installation shell 1 are provided with grooves 11 that are engaged with the buckles 21 .

[0013] In order to facilitate the positioning of this product, an installation platform 12 is provided on the top of the ink cartridge installation shell 1 , and a positioning platform 22 corresponding to the installation platform 12 is provided on the ink cartridge 2 . The groove 11 is arranged at the bottom of the installation platform 12 , and the inner side of the clip 21 is extended with a rib 211 matching with the groove 11 .

[0014] Of course, according to different needs, the clasp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com