Improved structure for light emitting diode (LED) lamp tube

A technology for LED lamp tubes and improved structures, which can be applied to lampshades, parts of lighting devices, semiconductor devices of light-emitting elements, etc., and can solve problems such as black areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

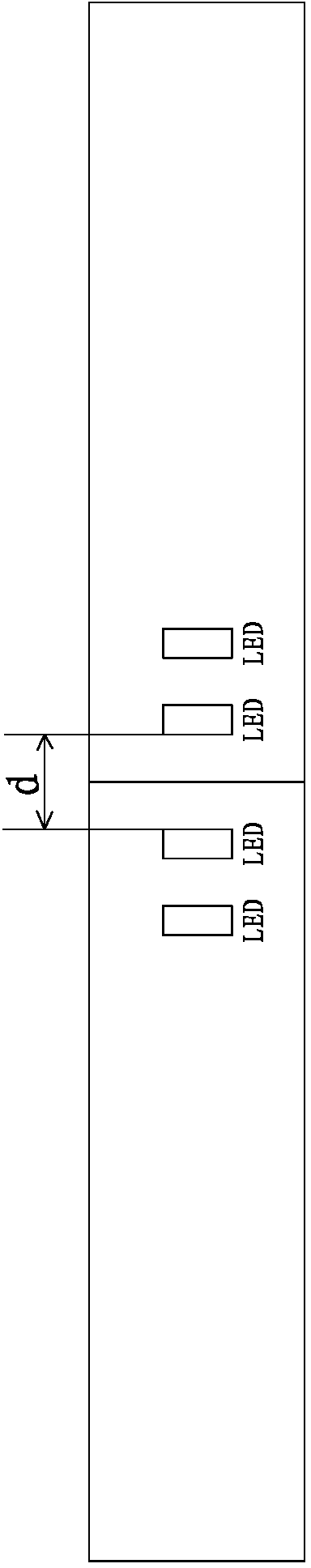

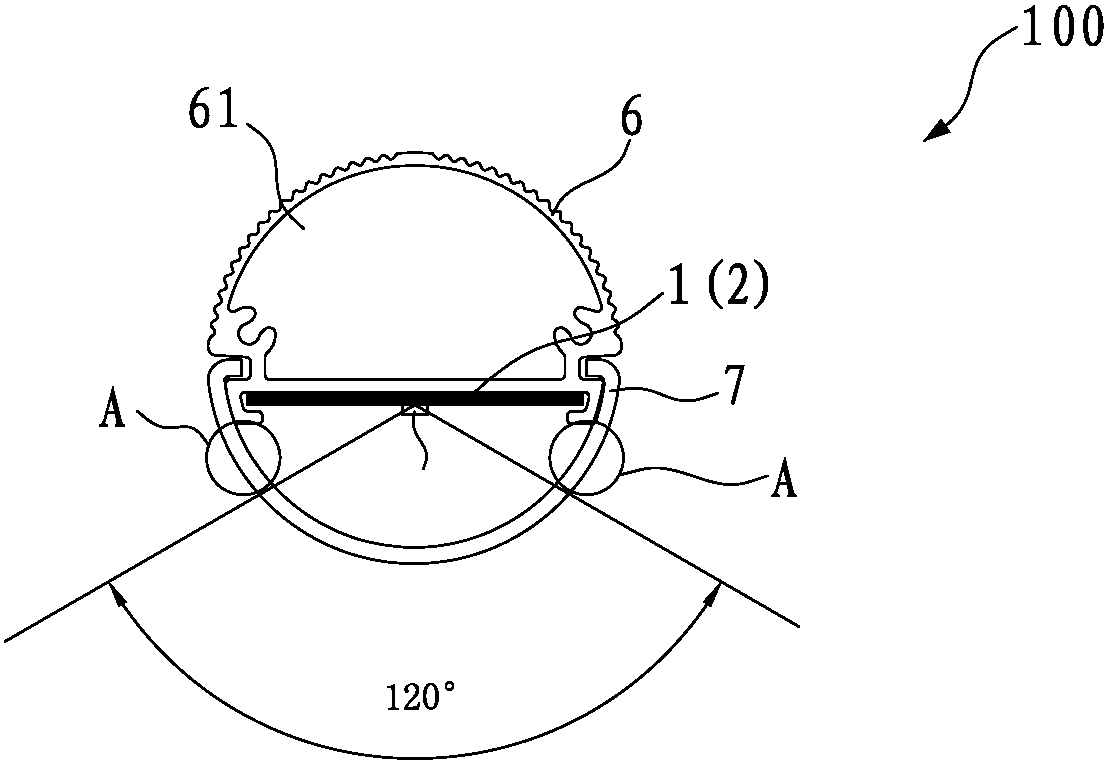

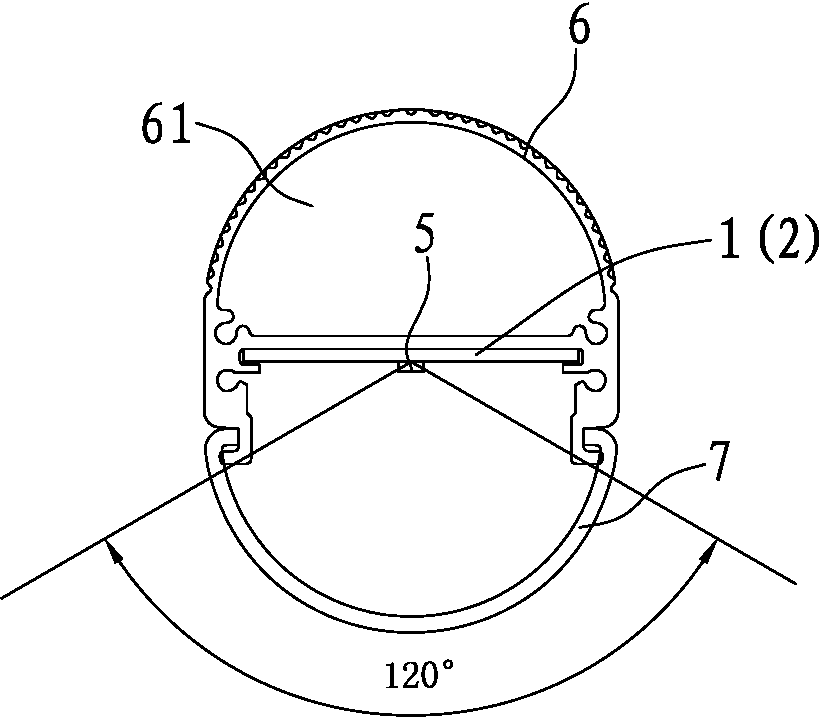

[0035] please compare figure 2 and image 3 As shown, it is a comparison between the prior art and the technical solution of the present application. In the prior art, the LED fluorescent lamp 100 also includes a casing 6 and a PC cover 7. The casing 6 and the PC cover 7 can be interlocked and interlocked Finally, a cavity 61 is formed, and the circuit board is accommodated in the cavity 61. Specifically, in this embodiment, the circuit board is composed of a first substrate 1 and a second substrate 2, that is, the first substrate 1 and the second substrate 2 are all contained in the cavity 61; because the existing LED fluorescent lamp 100 diverges light at 120 degrees, but the PC cover 7 does cover half of the entire shell 6, that is, it covers an angle of 180 degrees. Form a black area A at an angle of 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com