Battery thermal management control method

A battery thermal management and control method technology, which is applied in the field of automotive battery thermal management control, can solve the problems of energy waste, inability to efficiently control the temperature of battery modules, etc., and achieve the effect of minimizing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

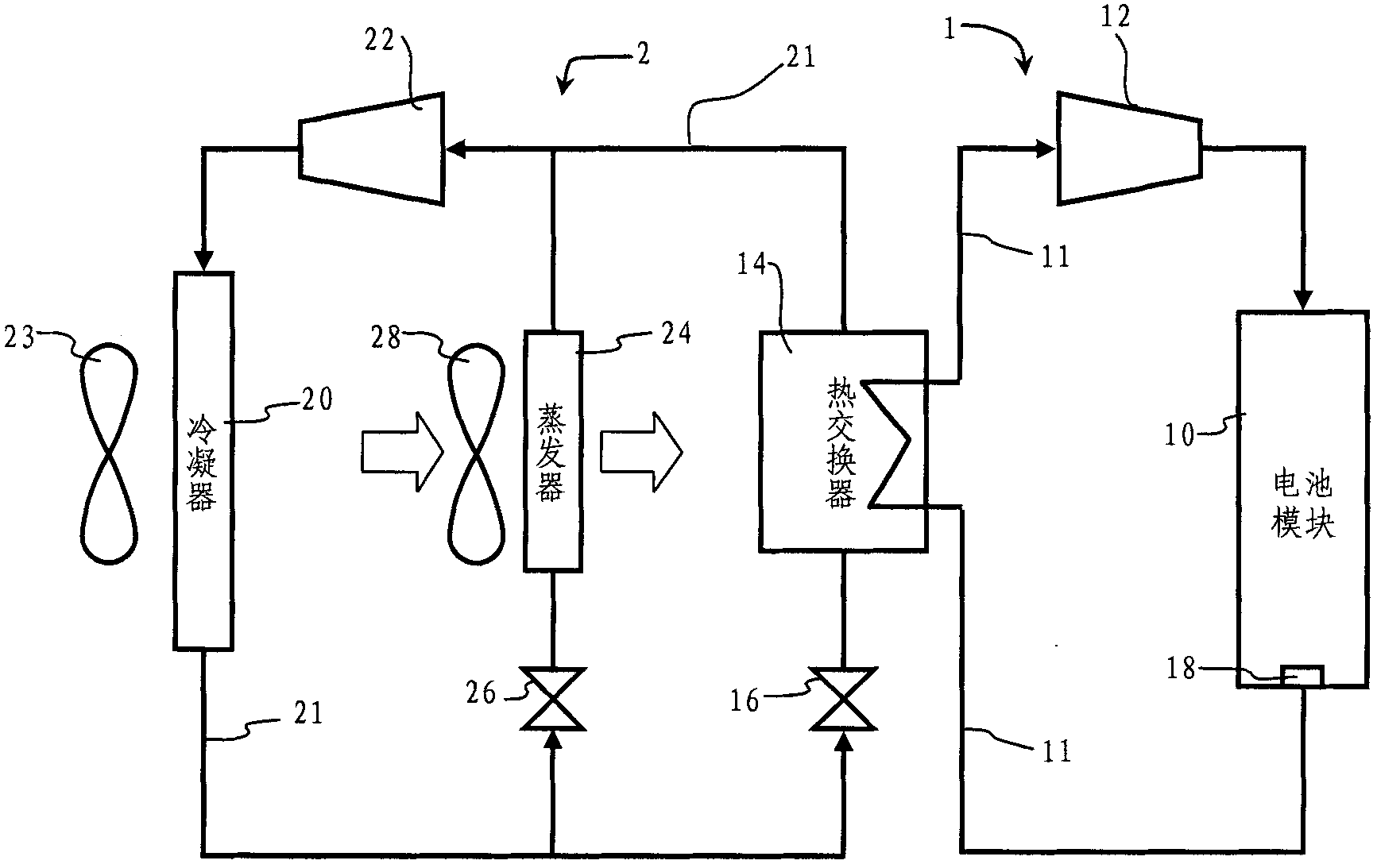

[0038] see figure 1 As shown, a vehicle battery thermal management system according to an embodiment of the present invention involves a battery cooling circuit 1 and an air conditioner refrigerant circuit 2 .

[0039] The battery cooling circuit 1 includes a water pump 12 , a battery module 10 and a heat exchanger 14 connected in sequence by a coolant conduit 11 . The water pump 12 can be driven electrically or mechanically, and drives the coolant to flow through the coolant conduit 11 and circulate through the battery module 10 and the heat exchanger 14 . The cooling liquid circulates in the loop communicated with the cooling liquid conduit 11 to form a cooling liquid circulation loop. In the coolant circulation circuit, when the coolant flows through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com