Automatic tea fixing machine and method

A technology for fixing greens and tea leaves, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of excessive coal ash and dust, poor taste and aroma, and unfavorable clean production in tea factories, and achieves energy saving, stable quality, and uniform feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

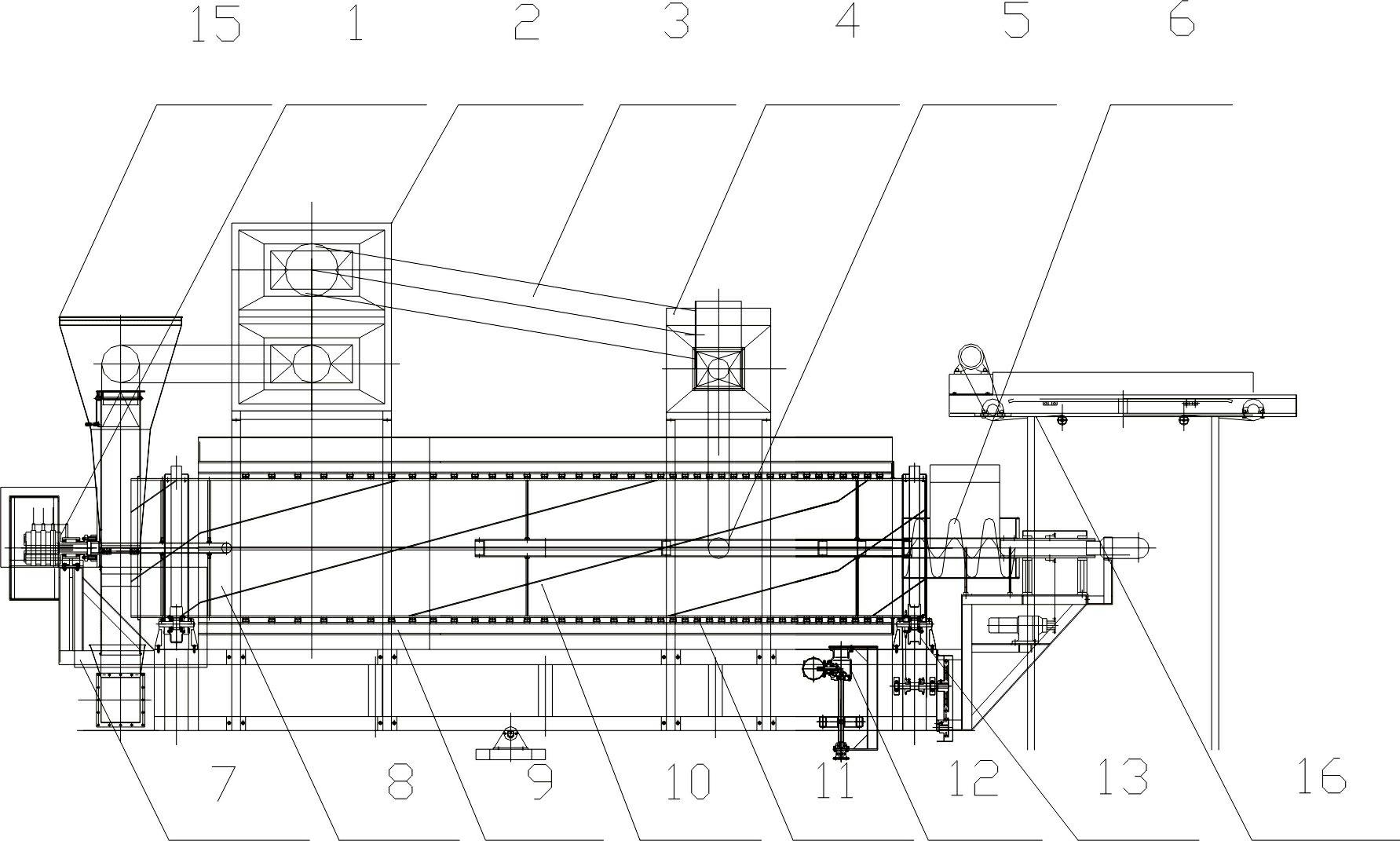

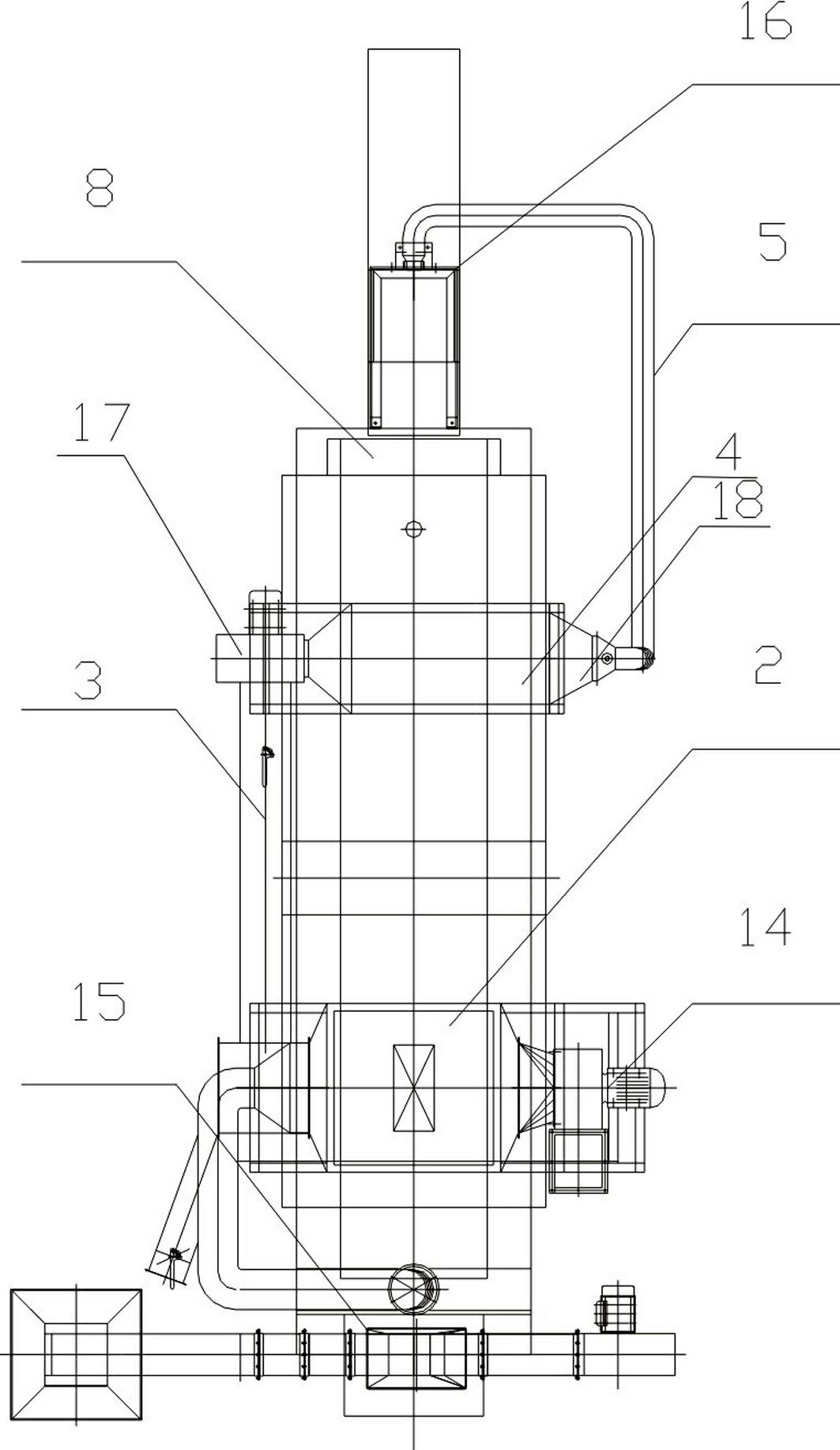

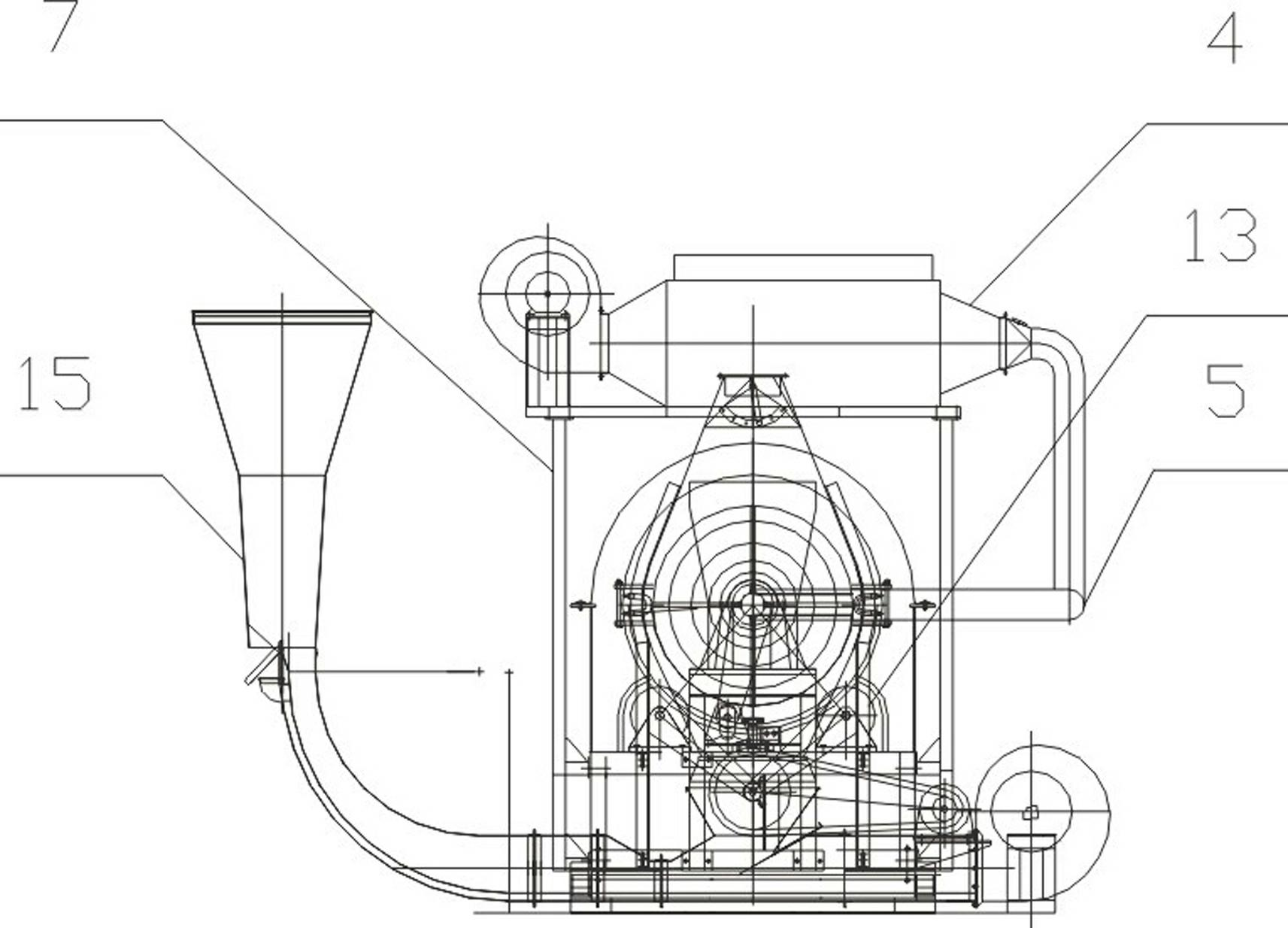

[0036] An automatic greening machine for tea, comprising a belt electronic scale 15, a frame 7, a rotating drum 8, an electric heating tube 11, a support mechanism, an inclination adjuster 12, a heater 4, a heater tube 5, a motor, a screw propeller 6, Humidity exhaust fan 14, winnowing machine 15, transmission mechanism. A screw propeller 6 is installed at the entrance of the rotating drum 8, a vane plate 10 is installed inside the rotating drum 8, and an electric heating tube 11 is fixed on the outer wall of the rotating drum 8; The air duct 5 is connected to the rotating drum 8; the waste heat recovery device 2 is installed on the top of the frame 7, and the waste heat recovery device 2 is connected to the dehumidification blower 14 through the waste heat recovery pipe 3.

[0037] One side of the frame 7 is provided with a belt electronic scale 16, and the belt electronic scale 16 is located above the entrance of the rotary drum 8.

[0038] An inclination adjuster 12 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com