An electrode heating device for high pressure test in liquid environment

A technology of electrode heating and high voltage test, applied in the preparation of test samples, material breakdown voltage and other directions, can solve the problem that electrode heating device is not suitable for high voltage test and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

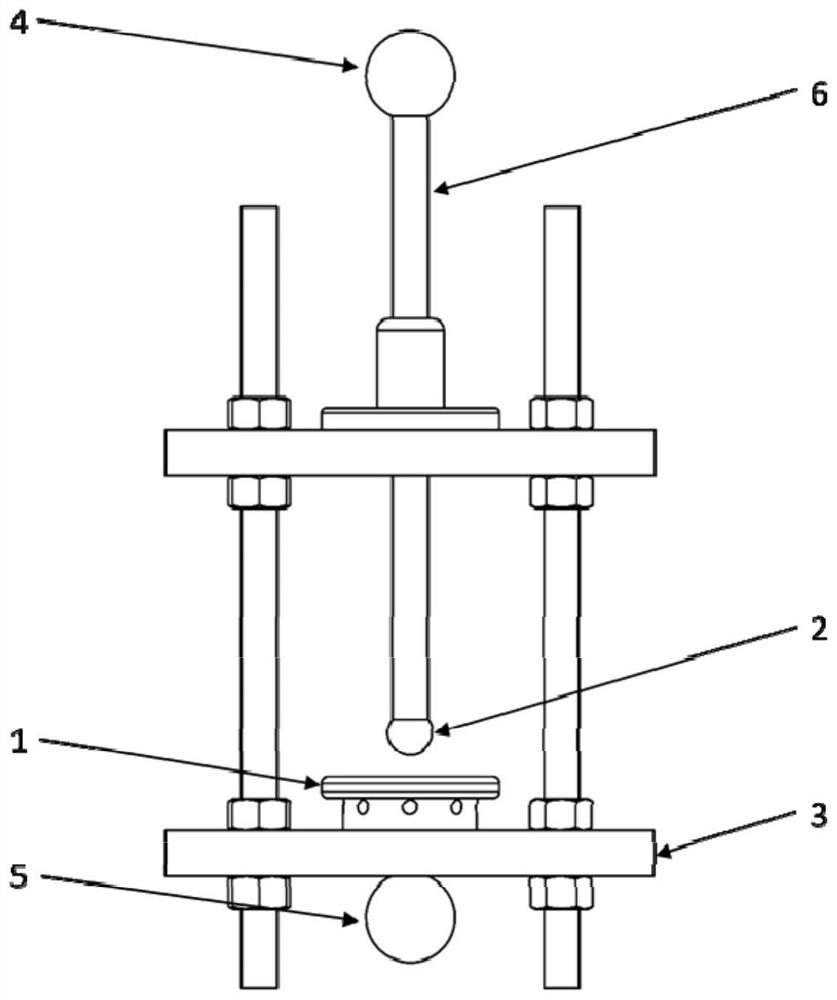

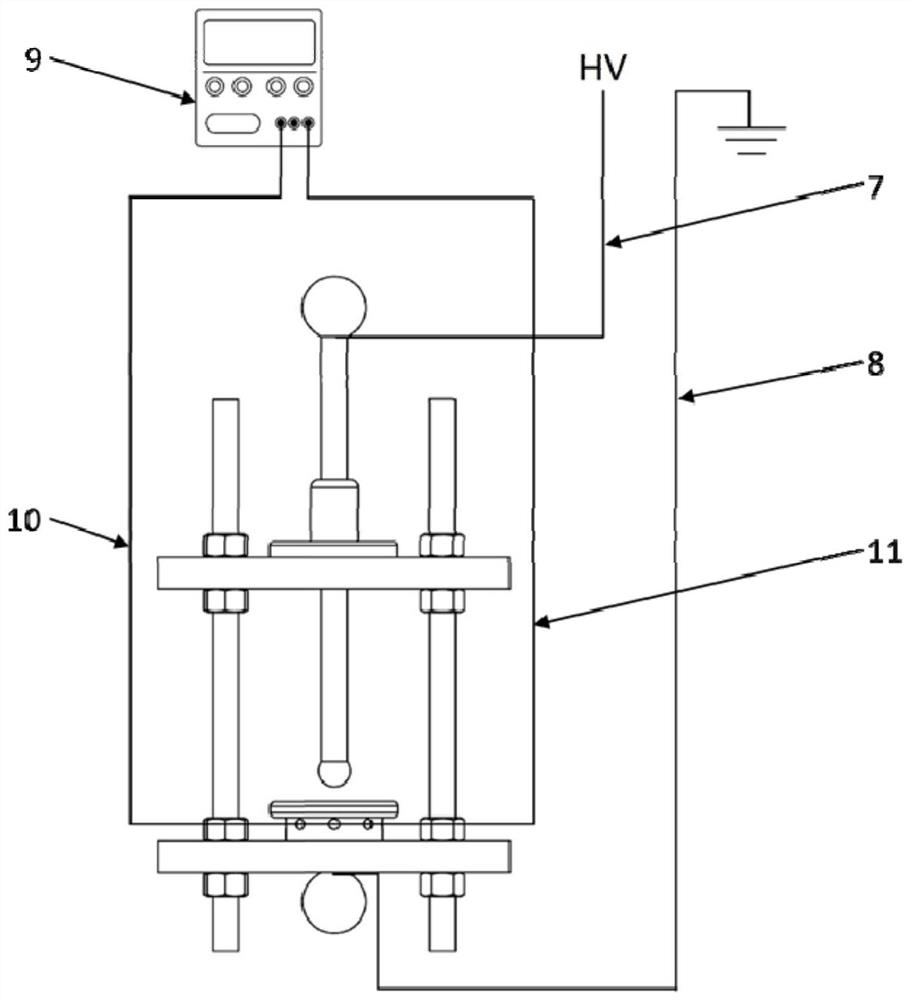

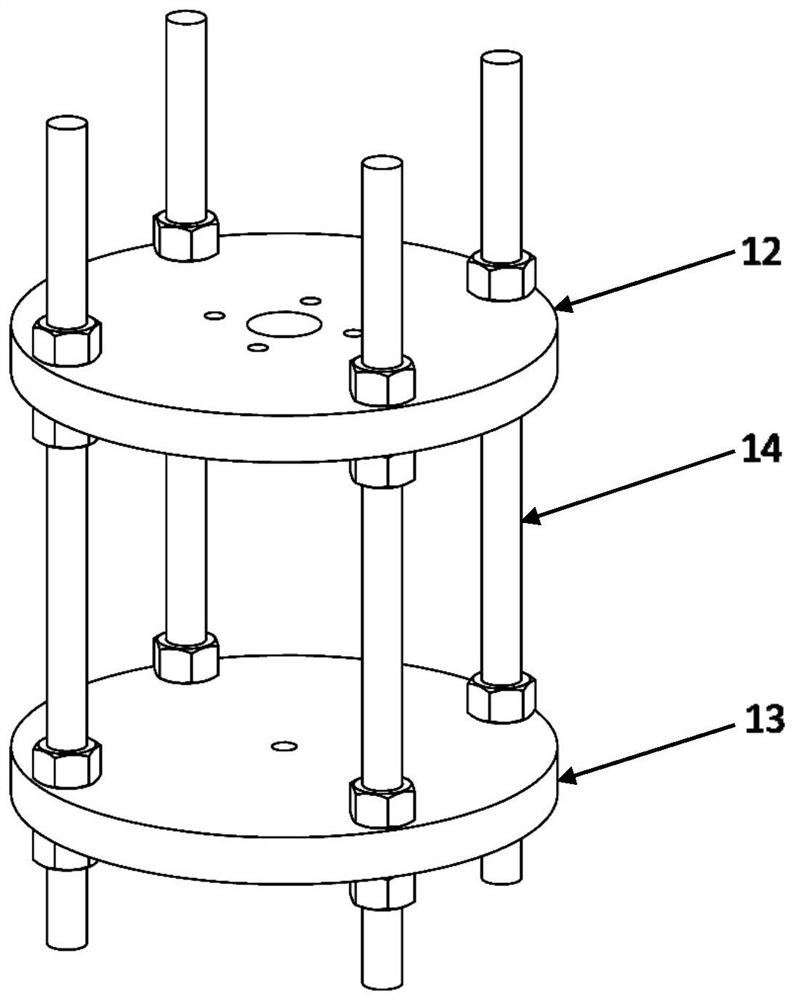

[0030] like figure 1 and figure 2 As shown, the electrode heating device of the present invention consists of a heating electrode 1, a high-voltage ball electrode 2, an electrode holder 3, a high-voltage side pressure-equalizing ball 4, a ground-side pressure-equalizing ball 5, a high-voltage connecting rod 6, a high-voltage lead 7, a grounding lead 8, and DC stabilized power supply 9 is formed.

[0031] One end of the high-voltage lead 7 is fixed between the high-voltage side pressure equalizing ball 4 and the high-voltage connecting rod 6, and the other end of the high-voltage lead 7 is connected to the high-voltage generator. The high pressure side pressure equalizing ball 4 is located on the top of the high pressure connecting rod 6, and the high pressure side pressure equalizing ball 4 is connected with the high pressure connecting rod 6 through a screw. The high-voltage ball electrode 2 is located at the bottom of the high-voltage connecting rod 6, and the high-voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com