Crank type rubbish bag chipper

A technology of garbage bags and shredders, applied in the direction of grain processing, etc., can solve the problems of land pollution, low efficiency, health hazards of operators, etc., and achieve the effect of no harm to health and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

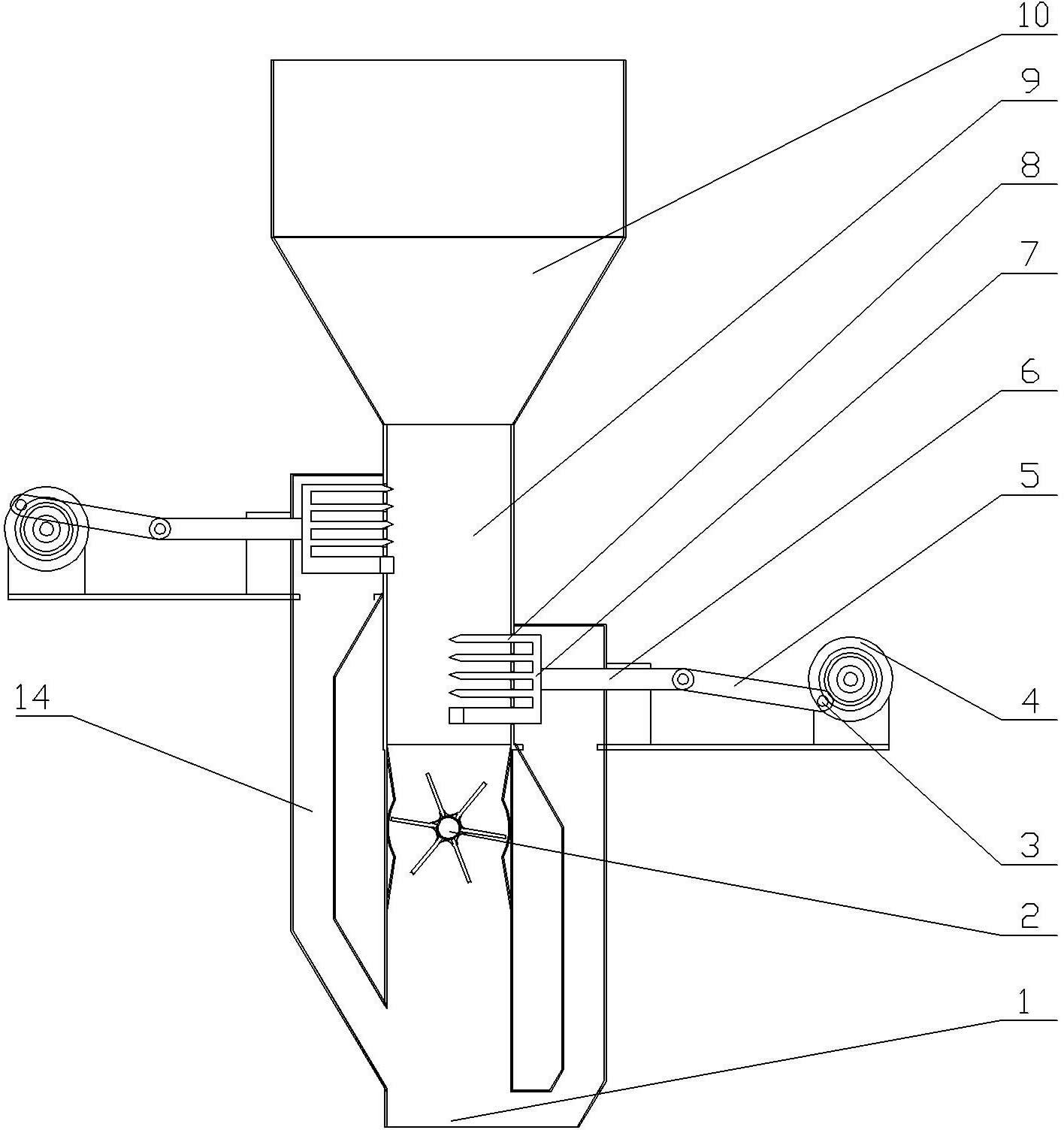

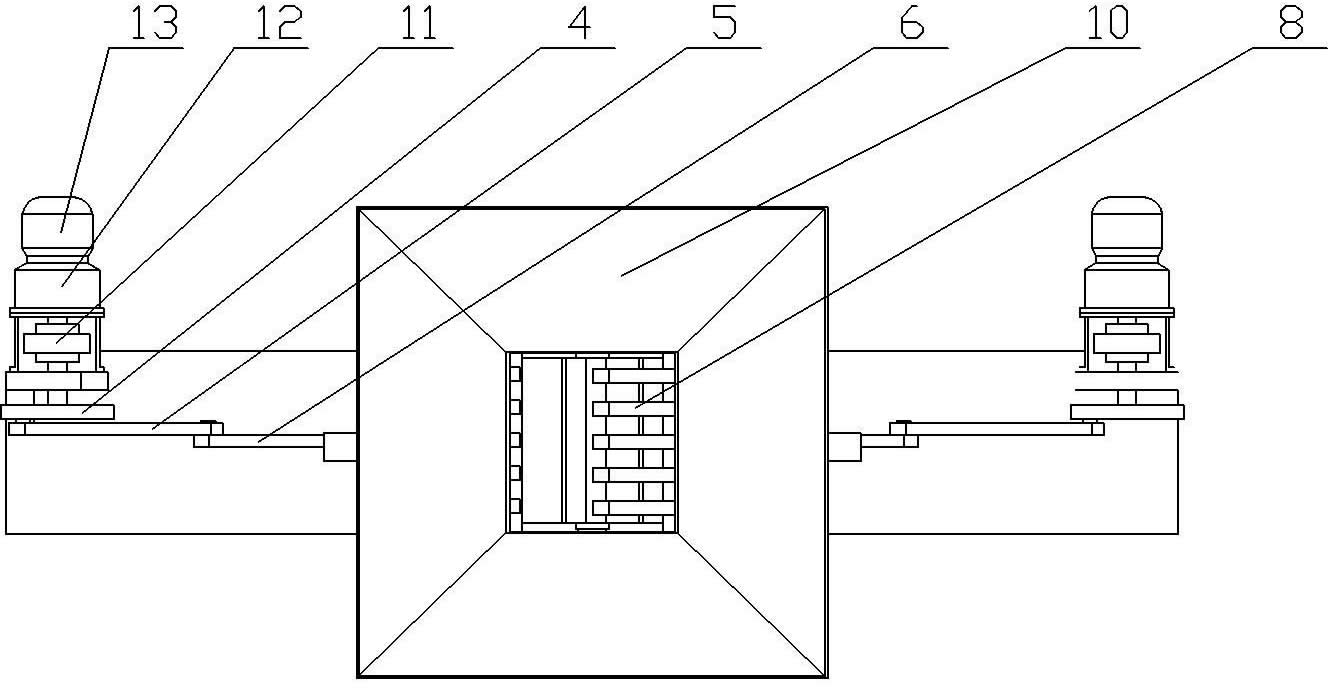

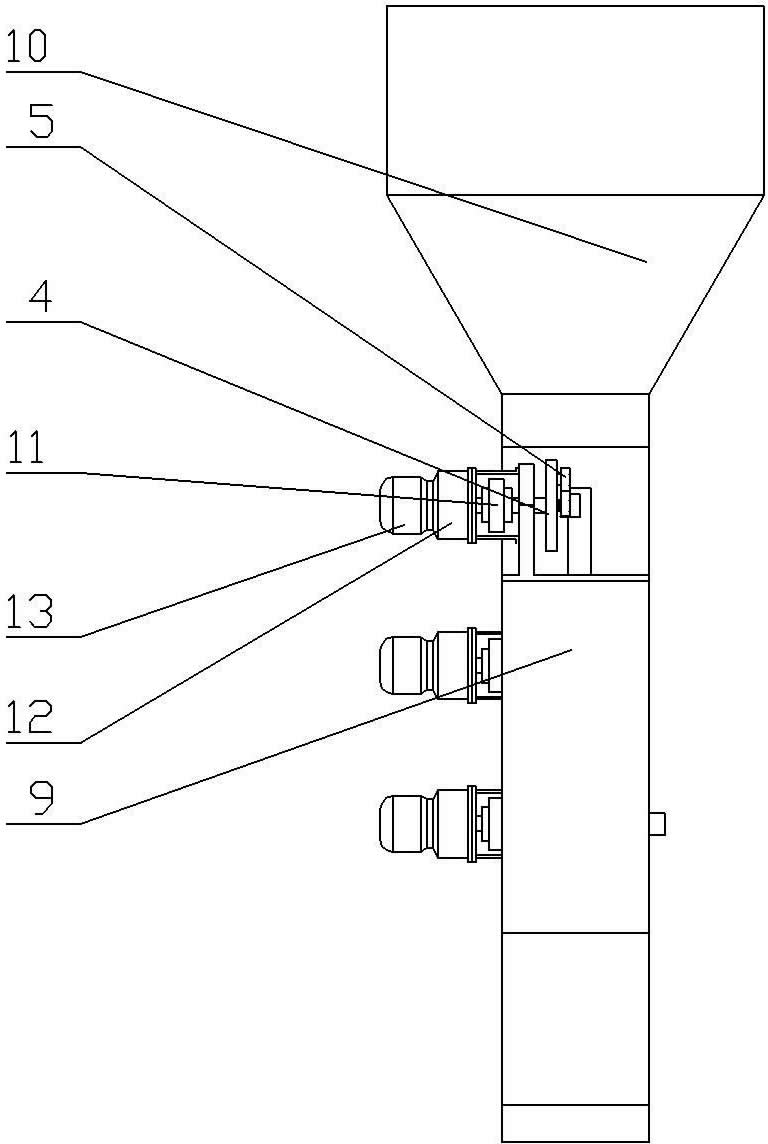

[0019] As shown in the figure, the present invention includes a bag breaking box 9, the upper end of the bag breaking box 9 is provided with a garbage bag inlet 10, and the lower end of the bag breaking box 9 is provided with a discharge port 1; the bag breaking box 9 is provided with a cutter 8 , The cutting knife 8 is arranged on the plunger cutter rest 7, and the plunger cutter rest 7 is connected with the power unit.

[0020] The garbage bag inlet 10 is a vertebral body whose lower end opening is smaller than the upper end opening.

[0021] There are two inserting and cutting knife rests 7, one is an upper inserting and cutting knife rest, and the other is a lower inserting and cutting knife rest; It is arranged at the lower right part of the bag-breaking box 9; it is cut by crossing and layered, and the cutting effect is good.

[0022] An air-closed discharger 2 is arranged between the plunger cutter holder 7 and the discharge port 1 . The air-closed discharger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com